With the target of 430 GW of renewable energy by 2030, Energy Storage in India offers a great opportunity for Advanced Lead Acid Batteries. We have been producing hydro and thermal power for several decades in India but only recently has the focus shifted to renewable energy and Lead batteries, highly recyclable & economical offer the required energy density. Shifting to new technologies always has some pains; while the established, technology with advances usually penetrate rapidly. However, some technologies straddle the gap between traditional technology and the new one that is projected to take over. In the case of energy storage, this is the space that Advanced Lead-Acid Batteries will take over. It has better energy density than traditional lead-acid batteries but does not suffer from the high production cost and recyclingbottlenecks associated with Lithium-ion batteries.

Why are batteries important?

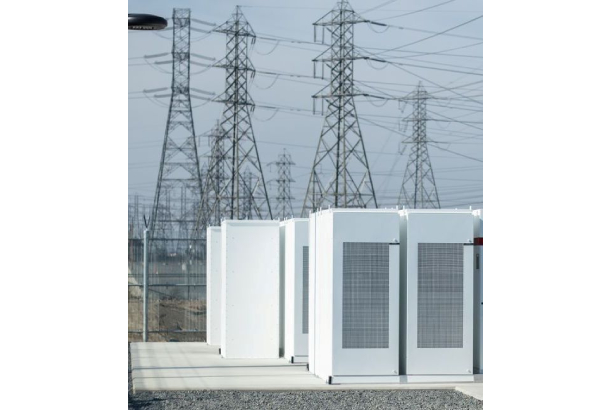

Generating power from non-renewable sources such as coal or nuclear energy does not need the storage of energy – one can increase or reduce the production at the source as per the energy demand. However, with renewable energy sources such as solar or wind energy, the production cannot be consistent. For example, most countries in the European Union go through an extended period without much sunshine during winter. It is therefore imperative that there should be a low-cost and reliable method to store excess energy generated for use during periods when either production dips, or demand spikes. Lead batteries have always stored electricity, as it is the oldest, most proven and reliable battery technology available to us today. The Indian government has recently launched the National Electric Mobility Mission, which will see increased usage of Lead batteries in electric two-wheelers and e-rickshaws. There are also the new vehicles and replacement battery sectors, which are a major consumer of Lead-acid batteries that power the vehicle’s electrical systems, ignition and starter motors.

Lead-acid batteries: a background

Lead-acid batteries are one of the oldest and most matured battery technologies, and one can find this product in several applications, including cars, UPS for computers, inverters for houses, and even grid-scale storage systems. They have a reasonable life and low costs compared to other battery types. However, their power density is low, which makes them quite unsuitable for certain applications like hybrid or electric vehicles. They have robust manufacturing and supply chains with the lowest production cost. At the end of its life, 99 per cent of a lead-acid battery can be recycled in a green manner, which is not the case with other battery technologies. That 99 per cent recycling rate of Lead is highest when compared to other regularly recycled items, like corrugated boxes (88.5%), steel cans (71%), newspapers or paper in general (67%), and aluminum cans (55%).

According to India Energy Storage Alliance (IESA), the Indian energy storage market is likely to double and is expected to grow to 70 GW by 2022. Therefore, the need for recycling Lead-acid batteries to ensure less dependence on Lead imports and to prevent harm to the environment. To this end, India Lead Zinc Development Association has urged State Pollution Control Boards/Committees to ensure that the awareness on eco-friendly recycling of batteries should be spread with the industry as well as the population.

L Pugazhenthy, Executive Director, ILZDA said, ‘Currently, a sizeable number of Used Lead-acid batteries (ULABs) are reaching unregistered recyclers who do not follow the required environmental norms and cause pollution. ULABs when recycled responsibly are not only safe for the environment but also propel the circular economy. A public awareness campaign will aid the regulatory boards in streamlining and bringing more and more unregistered recyclers under a legal recycling framework. Most importantly, it will make citizens and other stakeholders aware and responsible on how they can be a part of responsible recycling of the ULABs.’

Advanced lead-acid batteries: the next step

Advanced lead-acid batteries offer better energy density and more cycles before they start to lose capacity; they have a longer life compared to a standard lead-acid battery. At the same time, they do not give up any of the positives of the traditional lead-acid battery, which are low cost and energy for production, easy availability, high reliability, and a robust recycling ecosystem – India can recycle more than 3 million units per annum – that is kind to the environment.

Li-ion vs lead-acid batteries

Lithium-ion batteries have a few advantages compared to lead-acid batteries. For one, they have a volume energy density that is well over two times that of advanced lead-acid batteries. That makes them better in terms of weight as well, and their typical state of charge (SoC) operating window ranges from full discharge to a fully charged cell. Advanced lead-acid batteries have a typical SoC operating window of 20-100% charge. This is where the advantages of Li-ion batteries end versus advanced lead-acid batteries, however, the latter is comparable in terms of cycle life and efficiency and can run on a lower nominal voltage (2V vs 3.2V). There are other factors that need to be considered, like the fact that India as of now has no manufacturing capability for Li-ion batteries, and neither do we have any capacity to recycle them. This means that their cost, both in terms of purchase cost as well as impact to the environment, is very high. In fact, the rate of recycling of Li-ion batteries is very low even in developed markets – as of July 2019, an abysmal 2-3% in Australia and less than 5% in the EU and USA are collected and recycled. It is obvious that lead-acid batteries are still a better answer to our energy storage requirements.

Approximately 85% of the lead consumed in India is used to manufacture Lead-acid batteries. At present India’s consumption of lead, as per industry estimates, is put at 1.2 million tonnes of which about 225,000 tonnes come from primary lead produced by Hindustan Zinc.

Arun Misra, CEO, Hindustan Zinc said, “It is imperative to look at a product like a battery as a holistic solution to a problem. The world is going electric as it is more efficient and allows us to source energy from clean & green resources like wind and sun. In enabling this transition Advanced Lead-Acid batteries are a one-stop solution for India's future energy needs. One big green point is the recyclability element of Advanced Lead-Acid batteries which paves the way for a circular economy which makes them cost-effective as it is 99% recyclable, meaning new batteries can be made with the lead being used multiple times. Lead-Acid batteries act as the auxiliary medium in the new era of Lithium-Ion batteries in the energy & power space which will reduce India's dependency on imports. It is based on mature technology thus making it a better choice for India's future energy needs.

With their low cost of production and zero impact on the environment, thanks to their recyclability, Advanced Lead-Acid Batteries can play a strategic role in India’s energy storage market.