by Abhishek Agashe, Co-Founder & CEO, Elima

While in the business world, the phrase "closing the loop" is commonly used to indicate the completion of tasks and the achievement of goals. But with the world transitioning towards green revolution with a significant amount of focus on sustainability and its context of sustainability, "closing the loop" aims to decrease waste and resource usage by changing how products are managed throughout their life cycles. Within the circular economy, waste is minimized as products from today are transformed into raw materials for tomorrow, creating a closed loop system. According to a recent study by CII's 'National Circular Economy Framework' (NCEF), India's circular economy is projected to reach $2 trillion and is expected to generate 10 million jobs by 2050.

What is closed loop supply chain?

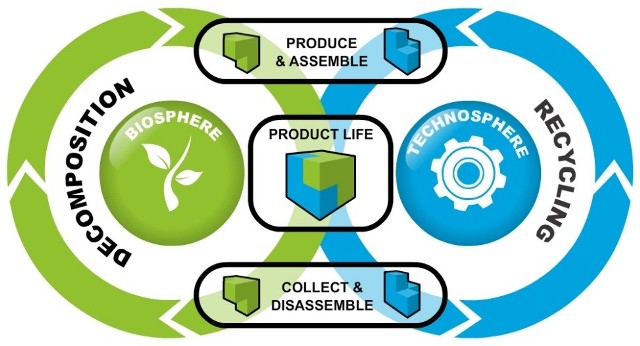

A closed-loop supply chain describes a setup where items and components undergo recycling, refurbishment, or remanufacturing to generate fresh products, thereby cutting down on waste and optimizing the use of resources. Embracing such a system is vital for promoting circularity, as it facilitates the ongoing utilization of materials and diminishes the demand for new resources. In this approach, products are engineered with recycling and reuse considerations, and materials are meticulously handled throughout their lifespan to maintain their value and utility.

Why it is must be embraced?

More and more businesses are adopting closed-loop supply chains as a crucial element in promoting sustainability within the framework of the circular economy. The circular concept can be likened to a "Butterfly diagram," symbolizing its transformation akin to the metamorphosis from a caterpillar to a butterfly. This transformation not only alters its physical appearance but also its fundamental essence. And now with the implementation of the Govt’s revised EPR policies, it has become a necessity for brands to instill in the brands DNA as EPR or Extended Producer Responsibility, is a cornerstone of waste management and sustainable resource use. It essentially means that manufacturers and producers take responsibility for the entire lifecycle of their products, including their disposal. By implementing EPR programs, we encourage producers to design products with recyclability and environmental impact in mind, and it incentivizes them to invest in processes that reduce waste and promote recycling. This not only helps to alleviate the burden on landfills but also contributes to the development of a circular economy where resources are kept in use for as long as possible, maximizing their value and minimizing environmental harm.

Technology as a catapult to drive the closed loop supply chain

The future to achieve circularity lies in leveraging technology, specially embracing tech like AI, IoT and data analytics to drive innovation to reshape traditional linear supply chains into sustainable, circular models. By leveraging advanced data analytics, efficient logistics, and creative solutions, technology is steering us towards a future where waste is minimized, resources are conserved, and businesses operate in harmony with the environment.

Data-driven approaches are pivotal in identifying opportunities to reduce waste and improve processes. By analyzing vast datasets collected across the supply chain, companies can pinpoint areas where materials are inefficiently used or wasted and implement targeted measures to address these issues. Predictive analysis can forecast changes in demand, enabling better inventory management and reducing the risk of overproduction and excess inventory, thus supporting waste reduction efforts. Additionally, innovative tracking systems, powered by IoT sensors and RFID tags, enable continuous monitoring of products and materials throughout their journey. This enhanced visibility allows businesses to optimize reverse logistics, identify inefficiencies, and streamline the return process, resulting in cost savings and improved resource management. IoT too plays a key role in understanding product usage, enabling repair & scheduling maintenance.

Furthermore, advanced technology-driven waste management solutions are instrumental in helping businesses transition to zero waste-to-landfill operations. By deploying sophisticated sorting and recycling technologies, companies can more effectively separate various types of waste, diverting recyclable materials from landfills and reintegrating them into the production cycle. Automated sorting systems equipped with AI algorithms accurately identify and separate recyclable materials, increasing recycling rates and reducing contamination.

Road Ahead

Overall, the future of closed-loop supply chains and circularity in India hinges on collaborative efforts among stakeholders, technological innovation, policy support, and consumer engagement. By embracing circular economy principles, India can strive towards a more sustainable and resilient future.