Tunnelling through challenges: TBM construction revolutionizing metro projects

by Raman Kapil, President & COO – Buildings & Infrastructure, Tata Projects

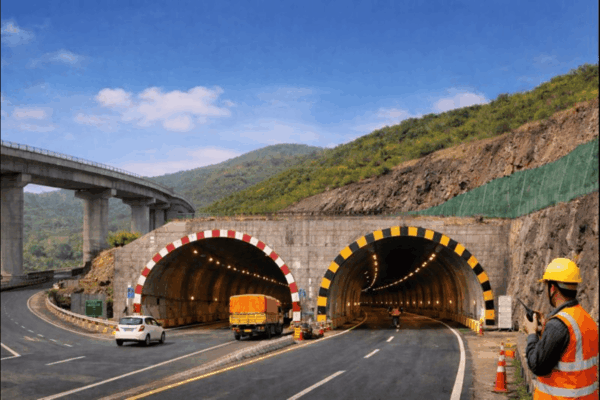

The demand for rapid connectivity from point A to point B is more pressing than ever, driven by immediate needs. As India's urban landscape evolves at a swift pace, the call for efficient and sustainable public transportation systems has never been more urgent. At the forefront of this transformation are metro rail projects, which are reshaping the way millions of Indians commute daily. A key factor driving the success and rapid implementation of these projects is the revolutionary use of Tunnel Boring Machines (TBMs) in underground construction. TBMs represent the pinnacle of modern tunnelling technology. These massive machines, often referred to as "underground factories," are capable of excavating through various soil and rock conditions while simultaneously installing tunnel support structures. The adoption of TBMs in metro projects has been a game-changer, offering numerous advantages over conventional tunnelling methods.

According to projects tracked by India Infrastructure Research, as of May 2024, there are more than 70 tunnels spanning a total length of approximately 220 km, which includes more than 40 under-construction tunnels (120+ km) and more than 20 in the planning stage (80 km) which majorly seem to be applying the TBM and cut & cover methods of tunnelling. In metro projects across India, from Pune to Delhi, the implementation of TBMs has significantly reduced construction timelines while minimizing disruption to the city life above ground. For instance, in the Pune Metro and Chennai Metro project, TBMs have been employed to create underground sections with remarkable efficiency. These machines operate with precision, creating smooth tunnel walls that require minimal additional finishing, thus saving both time and resources.

Accelerating progress with prefabrication

Enhancing the use of TBMs is the incorporation of prefabricated construction techniques, especially to ensurethe protection lining. This approach has led to the rapid completion of underground metro project, as evidenced in projects like the Lucknow Metro. By manufacturing key structural components off-site and assembling them on location, construction times are drastically reduced, and on-site disruptions are minimized.

A study published in the Journal of Construction Engineering and Management underscores the efficacy of such innovative approaches. The research found that collaboration tools related to Building Information Modelling (BIM) – often used in conjunction with TBM and prefab techniques – can reduce project delivery time by up to 20 percent.

Aligning with India's urban transit vision

The strategic use of TBMs and prefabricated construction aligns perfectly with India's ambitious vision to have operational metro networks in over 50 cities by 2025. This goal, part of the country's broader urban transit revolution, requires not just speed but also precision and quality in construction – attributes that modern tunnelling technologies deliver in spades.

Enhanced safety and quality

Beyond speed, the advanced technologies employed in modern metro construction significantly enhance the safety and quality of infrastructure. TBMs, with their controlled excavation process, reduce the risk of ground settlement and structural damage to nearby buildings – a critical consideration in densely populated urban areas.

Moreover, the precision of TBM-constructed tunnels, combined with the quality control possible in prefabricated components, ensures the longevity of the infrastructure. This translates to reduced maintenance costs for cities in the long run, making metro systems more sustainable both environmentally and economically.

Environmental considerations

The environmental impact of metro construction is another area where TBMs shine. By minimizing surface disruption, these machines help preserve the urban ecosystem. The reduced need for extensive excavation and the ability to reuse excavated material in construction further contribute to the sustainability of these projects.

Challenges and future outlook

While the benefits of TBM technology are clear, challenges remain. The high initial cost of TBMs can be a deterrent for smaller projects. Additionally, the complex nature of these machines requires specialized skills and training, highlighting the need for continuous workforce development in the sector. Further, unpredictable conditions and the coming up of unforeseen circumstances such as breakages and flooding lead to increased costs and delays.

Looking ahead, the future of metro construction in India seems promising. As cities expand and the demand for efficient public transportation increases, the importance of advanced tunneling technologies will only grow more significant. Innovations in TBM design, such as multi-mode TBMs capable of adapting to varying geological conditions, are set to further revolutionize the field.

India's infrastructure development is advancing significantly with the adoption of Tunnel Boring Machines and prefabrication technologies. These innovations aim to build smarter, safer, and more sustainable cities, paving the way for a more connected and efficient future. The synergy between urban planning and construction technologies will shape India's metropolitan landscapes.