Smart procurement, stronger infrastructure: How digitalization is solving complex challenges in construction

by Sakshi Katyal, Deputy Head of Procurement, Capacit’e Infraprojects

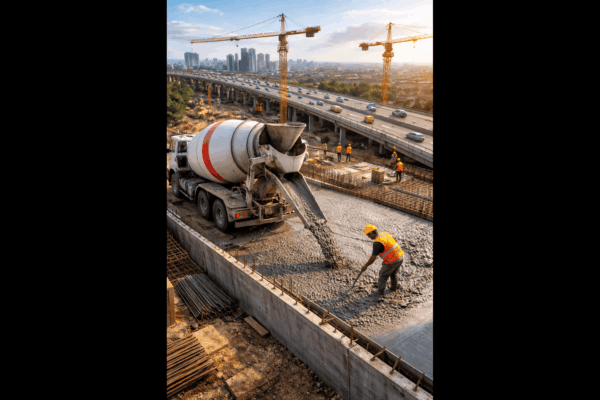

India’s construction sector is projected to contribute $1 trillion to the economy by 2030. Urban expansion, housing requirements, and increasing demand for data centres, logistics facilities, and public infrastructure are driving the need for steady project delivery. However, successful execution requires more than budgets and designs. It depends on accurate planning, predictable procurement, and efficient deployment of labour on the ground.

Procurement, once seen as a backend activity, is now central to project strategy. When integrated with digital systems, it offers better control over timelines, resources, and vendor coordination. At the same time, digital platforms are helping construction teams address long-standing issues in labour management, an area that continues to affect progress across sites.

Together, these changes are transforming not just what we build, but how we build it. Capacit’e Infraprojects is among the companies actively embracing these tools to enhance execution across high-rise and infrastructure projects.

Procurement: From Transactional to Strategic

Traditional procurement processes in construction rely on paper-based tracking, email approvals, and limited coordination between departments. This often results in late ordering, missed deliveries, and increased project costs.

Digital procurement tools provide project teams with visibility over material requirements, order timelines, vendor history, and pricing in a structured format. Dashboards reflect real-time updates, helping procurement teams adjust orders based on stock availability or changes in project scope. This reduces the risk of over-ordering or underestimating needs.

More importantly, procurement data from multiple projects can now be accessed centrally. This helps organisations evaluate vendor performance, compare pricing across regions, and identify sourcing patterns that improve efficiency. With budgets under pressure and timelines fixed, informed procurement decisions reduce uncertainty.

Labour Management: Addressing an Overlooked Gap

While materials and equipment have seen improvements, labour deployment still relies on outdated practices. Attendance is often marked manually. Workers are assigned based on verbal instructions. Subcontractors wait for updates over phone calls or fragmented messages.

This method leaves too much room for delays. Skilled workers remain underutilised. Contractors spend time coordinating rather than managing progress. Project delays accumulate, not due to design or engineering challenges, but because basic workforce planning is inefficient.

Digital labour management tools such as eFORCE now allow contractors to view daily headcounts, monitor attendance, and track output across tasks. Project managers can see which subcontractors have mobilised teams, which trades are on-site, and what progress is being made. Daily labour reports generated through mobile apps replace paper logs, improving both accuracy and access.

More importantly, companies are beginning to link productivity not just to task tracking but also to worker well-being. Investments in livable labour colonies and hygienic canteens are no longer viewed as compliance measures but as contributors to output. Workers who rest in cleaner, safer accommodations and have access to nutritious meals are more likely to show up regularly, remain focused, and deliver consistently. Healthier workforces reduce absenteeism and improve execution on site.

Digital tools reduce the guesswork in labour management. They shorten the time between identifying a manpower requirement and deploying the right team. When combined with improved living and working conditions, the result is a more efficient, more motivated workforce that helps projects stay on track.

Real-Time Coordination Through Shared Data

Execution often slows due to poor communication across teams—engineers, architects, procurement, site managers, and clients. Digital construction platforms solve this by offering a unified view of project data. Drawings, schedules, approvals, and site photos are accessible in one place. When site teams upload progress or delivery logs, senior managers stay updated without needing to be on-site.

This shared visibility speeds up issue resolution and keeps projects moving. It also supports compliance and audit readiness in government or public-private projects.

Real-time data enables faster, more accurate decisions. If a task is slipping, labour can be reassigned early. If a shipment is delayed, an alternate source can be activated before the work sequence breaks. Dashboards help contractors track multiple sites remotely, especially valuable for infrastructure players spread across locations.

Building Vendor and Labour Intelligence

Procurement systems like ERP now do more than track order values. They log delivery timelines, payment cycles, quality records, and issue resolution—creating a reliable performance history for each vendor and subcontractor. This allows project teams to select partners based on past delivery consistency, not just quoted rates, reducing reliance on unreliable suppliers and improving on-site continuity.

The same shift is happening in labour management. Digital platforms now maintain real-time databases of worker profiles, trade skills, and availability. Subcontractors can update manpower levels via mobile apps, enabling site teams to align deployment with task schedules. Labour is no longer mobilised reactively but planned in advance, reducing idle time and ensuring that safety checks, onboarding, and compliance are completed before work begins.

Together, these tools turn procurement and workforce planning into repeatable, data-informed processes. Over time, performance insights help identify region-wise vendor strengths and workforce efficiencies, supporting strategic sourcing and smoother execution across projects.

Construction Technology and Its Practical Value

Construction Technology now reflects the practical application of digital tools in construction, not as a category, but as a working system. It helps align design, procurement, labour, compliance, and execution into one trackable flow.

Project heads can use this system to plan backwards from deadlines, identify dependencies, and spot bottlenecks. From smaller residential developments to national-level infrastructure projects, the principle remains the same: structured coordination improves delivery.

As the size and complexity of projects grow, digital systems bring predictability to work that was previously difficult to track in real-time.

What This Means for the Sector

India’s infrastructure plans are wide-ranging. They require thousands of contractors, millions of workers, and coordination across central and state departments. The pressure to deliver on time and within cost is high.

Smart procurement and digital labour management will not solve every problem in construction. But they reduce the number of preventable delays. They bring order to processes that were previously fragmented. They improve data access for decision-makers. Renowned companies like Capacit’e Infraprojects continue to invest in these systems to build smarter, faster, and more sustainably.

Conclusion

The construction sector has focused heavily on design and material innovation. But some of the biggest operational gains are now coming from how well teams are able to plan, procure, and manage their workforce.

Digital procurement systems and labour management tools bring structure, accountability, and speed. They are practical solutions to long-standing execution issues. As infrastructure investments scale up across India, these tools will help maintain clarity where it matters most, on the ground.

Smart procurement is not about software adoption. It is about giving project teams the ability to make decisions based on accurate, timely data. And when that happens consistently, stronger infrastructure follows.

Tags