Sapura Energy sets new standards in wellhead platform delivery and installation

Building and transporting heavy platform jackets is a complex process under normal conditions. However, Sapura Energy Berhad had just one year to build three jackets in Malaysia and transport them to Al Shaheed Field, Qatar’s largest offshore oil field. Managed by North Oil Company (NOC), this field includes 33 platforms spread across nine areas.

To enhance production capacity, NOC initiated the USD 60 million Al Shaheen Phase 2 project, which involved installing seven new wellhead platforms (WHPs) in two batches. Sapura Energy, as the engineering, procurement, construction, installation, and commissioning (EPCIC) contractor, was responsible for delivering three WHP jackets, encompassing design, fabrication, transportation, and installation.

The project faced a significant challenge: delivering the WHP jackets within a tight 12-month timeframe. All structures were to be fabricated in Malaysia, and traditional towing methods would require at least 40 days to reach Qatar, leaving only 10.5 months for design and construction. Sapura Energy was challenged with finding the best way to transport the jackets on time and within budget.

Navigating challenges with efficient transport

Sapura Energy proposed transporting all three barges with the WHP jackets (8,000 metric tons total mass) onboard a large semi-submersible vessel, the OHT Albatross. This vessel, capable of sailing at 10 to 13 knots, would reduce the transit time to just 14 days. “The real challenge for this operation was to prove and convince NOC to accept the idea,” said Mohd Fariq Billah, lead naval architect at Sapura Energy. “There were significant concerns due to the arrangement of the BARGE at a right angle with the semi-submersible vessel, resulting in an excessive overhang of approximately 28 meters on both sides.”

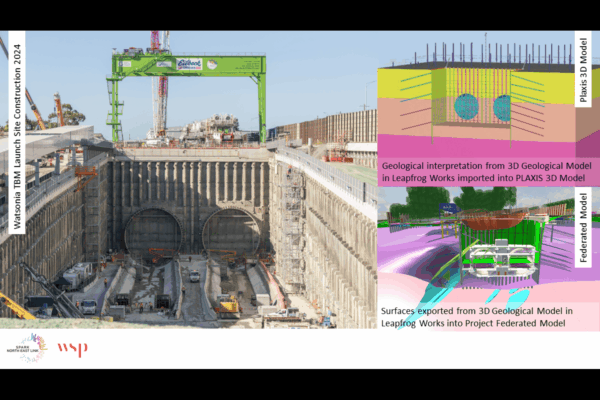

To ensure that the vessel was the most viable option, the team’s transportation and installation engineering group needed to conduct a detailed study, requiring finite element analysis (FEA), hydrostatic and hydrodynamic analysis, and structural analysis software to assess the barge strength, stability, and vessel motion.

Optimizing vessel selection with advanced analysis

After considering their options, Sapura Energy used MOSES to calculate vessel stability, mobility, and longitudinal strength. The application’s finite element analysis capabilities were used to study how the semi-submersible and its cargo would interact with ocean waters from Malaysia to Qatar, allowing Sapura Energy to choose the optimal barge. The team also used SACS to model the jackets, piles, and barges, and then perform a frequency domain analysis to evaluate the performance of both wider and smaller breadth vessels. SACS was used to model jackets and other materials carried by the semi-submersible. These models were then transferred to MOSES, taking advantage of the interoperability of Bentley products.

The analysis revealed that a smaller vessel, despite having a lower GM value, offered better stability and reduced dynamic roll angles, making it a safer and more cost-effective option. The sea state during transportation was forecast to consist of wave periods between 8 and 12 seconds with a significant wave height between 4 and 5 meters. A slimmer vessel was the preferred choice due to its favorable seakeeping characteristics in transportation compared to wider vessels. The innovative transportation strategy involved careful vessel ballasting and ensuring the barge overhangs would not submerge during transit. This approach not only saved time, but also reduced costs by avoiding multiple tug hires.

Setting new benchmarks in offshore transportation

By implementing MOSES and SACS on this project, Sapura Energy significantly reduced transportation time. “We transported the three barges from Malaysia to the Al Shaheen Field in approximately 14 days, compared to at least 40 days with traditional towing methods,” explained Billah. “This saved over 50% in transit time, crucial for meeting the project’s 12-month schedule.” They were also able to lower transportation costs by 40% through the use of a single semi-submersible heavy-lift vessel instead of multiple tugboats. But perhaps most importantly, the team was able to ensure the safe delivery of structures with minimal risk of submersion or damage.

The successful delivery and installation of the WHP jackets set a new benchmark for Sapura Energy and NOC. The project demonstrated the effectiveness of using a semi-submersible heavy-lift vessel for transporting large offshore structures. This innovative approach has enhanced Sapura Energy’s reputation and highlighted their capability to undertake similar projects in the future. “The successful use of MOSES software to simulate the selected vessel’s adequacy and expected behavior while transporting large and risky cargo within allowed tolerances gave us the ability to deliver projects that make possibilities a reality,” said Billah. “This achievement paves the way for many more future projects, opening paths to even more innovations in the region.”

Tags