The future of zero-waste construction: A new frontier in real estate

by Vivek Joshi, Head – Operations & EPC, Viceroy Properties

The construction and real estate industry stands at the threshold of a transformative era. With global climate imperatives and resource constraints tightening their grip, zero-waste construction is emerging not just as a green ideal but as a critical frontier that will define the future of real estate development.

India, with its massive urbanization drive and growing demand for quality housing, has a unique opportunity to lead this shift. For real estate companies like Viceroy Properties, the journey towards zero-waste is not just an environmental commitment – it is a business imperative that enhances operational efficiency, customer value, and brand leadership.

Understanding zero-waste in construction

Zero-waste construction refers to building practices that aim to eliminate waste sent to landfills through reduction, reuse, recycling, and recovery of materials. According to industry estimates, construction and demolition activities account for nearly 25-30%* of solid waste generated globally. In India alone, more than 150 million tonnes** of construction waste is produced annually – a number expected to rise as urbanization accelerates.

Yet, the future doesn't have to mirror the past. Advances in material science, modular construction, digital design tools like Building Information Modeling (BIM), and more sophisticated waste management systems are making zero-waste targets increasingly achievable.

From theory to practice: The Viceroy experience

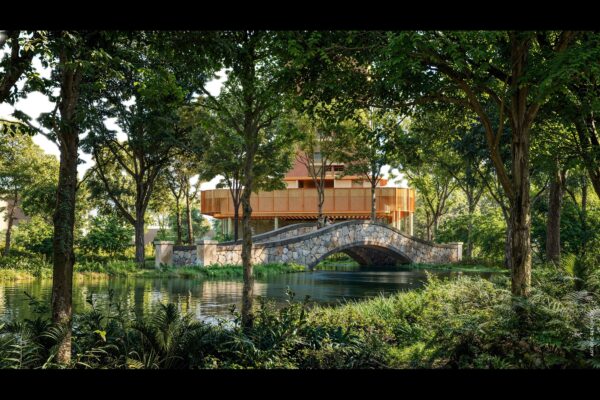

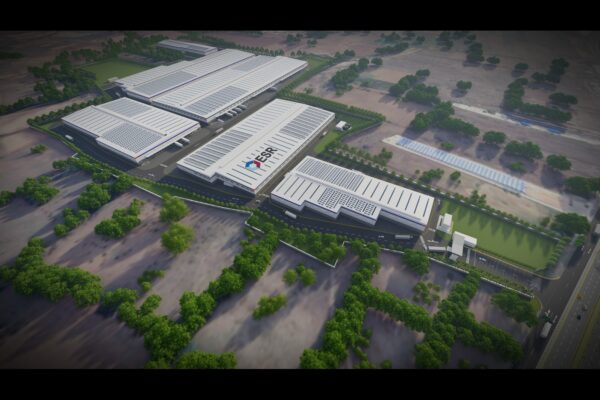

At Viceroy Properties, our projects—such as Viceroy Savana and Viceroy Prive in Kandivali East, Mumbai – have served as living laboratories for deploying more responsible construction practices.

Our project Viceroy Savana currently meets the IGBC Green Homes Gold Level rating with 77 achievable points as part of the IGBC Green Homes Feasibility Study Report. At Savana, we adopted meticulous material planning to reduce on-site wastage. By partnering with suppliers who provided precut and pre-shaped materials, we minimized surplus inventory. Leftover concrete was systematically repurposed for non-structural works, and metal scraps were recycled back into the supply chain. Our compliance with MOEF regulations and additional tree plantation drives further underscores our dedication to reducing our carbon footprint.

Specific practices include:

- Green procurement: We prioritize products and materials with lower environmental impacts throughout the design and construction phases.

- Structural design optimization: We used alternative materials for RCC mix, including fly ash, to enhance structural durability and reduce environmental impact. Steel rebars with couplers further optimize material efficiency.

At Viceroy Prive, our ongoing landmark project will also work to receive the prestigious IGBC Green Homes Certification. We have gone a step further by integrating digital construction management tools that track material usage in real time. This helps in dynamically adjusting procurement to prevent over-ordering and reduces the environmental burden of excess material handling and storage. Waste segregation at source has also been mandated across all contracting partners on site.

Multiple forces are converging to make zero-waste construction an industry standard rather than an exception:

- Stricter environmental regulations: Indian cities like Delhi, Mumbai, and Bengaluru are enforcing stricter norms on construction and demolition waste disposal. Compliance with Solid Waste Management Rules 2016 and Construction & Demolition Waste Management Rules 2016 is now mandatory. Developers failing to manage waste responsibly face penalties and delayed clearances.

- Operational and financial gains: Waste equals cost. Every kilogram of unused material represents sunk cost in procurement, transport, and disposal. Zero-waste construction improves project margins by reducing material losses, minimizing disposal fees, and cutting storage costs. Modular construction alone reduces wastage by up to 50% and slashes timelines by 20-50%. More efficient sites also see less rework, faster handovers, and enhanced labour productivity.

- Customer demand for green living: Indian homebuyers, especially in premium and luxury segments, are now prioritizing sustainability. Green-certified homes command higher marketability and resale value. A Knight Frank survey found that 73% of Indian respondents consider green credentials important when buying property.

- Supply chain readiness: India's ecosystem of recycling partners, prefabrication suppliers, and green material vendors has matured, making zero-waste operationally feasible. Materials like fly ash, recycled aggregates, and green-certified tiles are now readily available. Closed-loop supply chains are becoming viable in urban centers, enabling developers to send back waste for reuse.

- Brand leadership and competitive advantage: Developers who adopt zero-waste models can differentiate their brand, win customer trust, and appeal to investors increasingly focused on Environmental, Social, and Governance performance. At Viceroy Properties, our visible commitment to responsible construction at projects like Savana and Prive enhances stakeholder trust and market leadership.

Innovations Powering the Zero-Waste Revolution

Modular and prefabricated construction: Shifting construction to controlled environments reduces on-site waste dramatically.

Recycled and green materials: Use of fly ash bricks, recycled aggregates, and low-VOC paints is on the rise.

Digital Twins and BIM: Advanced modeling prevents design clashes, reduces errors, and improves material estimation.

Circular economy models: Developers form partnerships with recycling firms to close waste loops and monetize scrap materials.

Challenges on the Road Ahead

Despite the progress, scaling zero-waste practices industry-wide faces hurdles:

Fragmentation in India’s construction supply chain limits consistency

Absence of universal waste measurement and reporting protocols

Recycling infrastructure remains inadequate in tier-2 and tier-3 cities

However, as marquee projects adopt best practices and set new benchmarks, these challenges can be overcome by collective industry action.

The way forward

The future of real estate lies in embracing a circular construction economy where waste is viewed not as a byproduct but as a resource. As developers, we must collaborate with architects, engineers, contractors, and policymakers to institutionalize zero-waste norms and create standard operating procedures that can scale.

At Viceroy Properties, our commitment is to push the frontier – turning every new project into an opportunity to innovate and improve. Zero-waste is not a destination but an evolving journey. Projects like Savana and Prive are just the beginning.

As the real estate sector moves towards this new frontier, those who lead today will define the cities of tomorrow—cleaner, greener, and built not just to last, but to sustain.

*Source: World Bank, "What a Waste 2.0"

**Source: Centre for Science and Environment, 2023