Strategic network optimisation: Transforming India’s supply chains through effective planning

by Abhishek Baheti, Co-Founder – Strategy and Network Buildout, MatchLog Solutions

India's logistics sector, valued at over $250 billion in 2023, plays a vital role in driving economic growth but suffers from inefficiencies costing the nation an estimated 14% of its GDP annually. Issues like delayed shipments, fragmented networks, and high operating costs hinder India's ambition to emerge as a global manufacturing hub. Strategic network optimisation presents a solution by reimagining supply chains to be agile, resilient, and customer-focused. For a geographically diverse nation, optimising supply chains is critical to unlocking efficiencies and staying competitive in a world driven by speed, sustainability, and digital transformation.

Challenges unique to India

India’s logistics sector faces significant challenges due to its over-reliance on road freight, with 60 percent of goods transported by road. This dependency makes supply chains vulnerable to delays caused by poor infrastructure, traffic congestion, and unpredictable weather conditions. The lack of multimodal integration further exacerbates inefficiencies, even as initiatives like the PM Gati Shakti National Master Plan aim to address these bottlenecks. Additionally, the rapid growth of e-commerce has elevated consumer expectations for faster deliveries and enhanced last-mile connectivity. Small and medium enterprises, which form a significant portion of the economy, often struggle to access efficient and cost-effective supply chain solutions. These interconnected challenges require more than temporary fixes and call for long-term, strategic interventions.

Strategic network optimisation

Strategic network optimization is a comprehensive approach that involves analyzing, designing, and refining supply chain networks for maximum efficiency, scalability, and resilience. This process is built on three key pillars: data-driven decision-making, multimodal integration, and demand forecasting. By leveraging data, supply chain stakeholders can identify inefficiencies, predict demand trends, and optimize routes. For instance, artificial intelligence can evaluate historical shipment data to address bottlenecks and improve real-time operational efficiency.

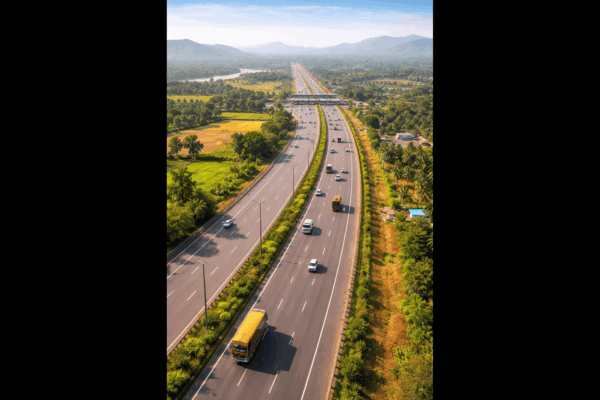

Multimodal integration is another critical aspect of optimisation. Combining road, rail, air, and waterways enhances flexibility and cost-efficiency, with solutions like shifting long-haul freight to rail or coastal shipping capable of reducing costs by up to 30% while cutting carbon emissions. Furthermore, accurate demand forecasting helps prevent overstocking or understocking, improving inventory management and customer satisfaction. Redesigning distribution centers closer to demand hubs can significantly reduce lead times and enhance service delivery.

Key benefits of optimisation

The benefits of strategic network optimisation go beyond cost reduction. By cutting fuel consumption, minimizing idle times, and optimizing inventory, businesses can achieve cost savings of up to 20 percent. It also enhances resilience, allowing supply chains to handle disruptions caused by monsoons, geopolitical issues, or labour strikes through robust contingency planning.

Sustainability is another major advantage. Optimization reduces carbon footprints through efficient route planning and load consolidation, aligning supply chains with environmental objectives. Moreover, improved delivery speeds, greater order accuracy, and real-time tracking create a superior customer experience, fostering loyalty and repeat business.

India’s opportunity to lead

India’s location as a gateway to Asia positions it uniquely to optimize supply chains both domestically and internationally. Initiatives like the Sagarmala Project, focused on port connectivity, and dedicated freight corridors, aimed at easing road traffic by shifting freight to rail, offer significant potential when integrated with strategic planning. Emerging technologies are also transforming logistics. Digital twins enable businesses to simulate and refine network designs before implementation, while blockchain enhances transparency and trust in operations, crucial for seamless collaboration with stakeholders.

Overcoming implementation challenges

Despite its promise, network optimization faces challenges. High upfront costs for advanced technologies like AI, IoT, and digital twins deter adoption, especially for MSMEs. Public-private partnerships and subsidies can help mitigate these barriers. Additionally, resistance to change among stakeholders requires education and clear demonstration of long-term benefits to ensure buy-in.

Data silos also hinder efficiency, as fragmented information limits collaboration across supply chain partners. Real-time data-sharing platforms can dismantle silos and foster transparency. Regulatory complexities, including inconsistent state-level policies, further complicate logistics operations. Streamlining and harmonising regulations will be essential to achieving long-term success.

Conclusion

For India to achieve its full potential as a logistics powerhouse, businesses must prioritize strategic, data-driven supply chain management over short-term cost-cutting measures. Collaboration among industry leaders, policymakers, and technology providers is essential to creating an ecosystem focused on efficiency, sustainability, and resilience. With India poised to become a $5 trillion economy by 2027, the time for action is now.