Driven by government mandates for accelerated project timelines and infrastructure modernization, precast concrete is gaining prominence as a strategic construction technology—offering standardized quality, reduced on-site labor dependency, faster execution, and enhanced compliance with safety and sustainability norms across all the infrastructure sector. With galore of infrastructure projects in the pipeline, the demand for precast concrete would soar in the coming years

As part of my daily routine, I commute to my workplace by train – like millions of others in Mumbai. On some days, I’m lucky enough to get a window seat; on others, I settle for the fourth seat or end up standing. One morning, as the train slowed near a familiar stretch, I noticed a plot of land being enclosed with metal sheets. Curious, I later found out that a major real estate project was coming up there. It was just a quick glance through the window—but enough to pique my interest.

After a week of missing that view – and a brief work trip to another city – I was back on my usual route. This time, luck was on my side again: I got the window seat. What I saw amazed me. In such a short time, the site had transformed. A building had already reached the fourth floor. The pace of construction was striking. I watched as massive concrete slabs were being hoisted and set into place with remarkable speed and precision.

The Eureka moment for me – it was precast concrete in action.

In earlier years, precast concrete wasn’t widely used- perhaps because the technology was relatively new and more expensive compared to traditional construction methods. The conventional approach, which we’re all familiar with, is the brick-and-mortar method. This age-old technique, the most common in India, relies on bricks bonded with cement mortar and has been the backbone of the country’s building practices for centuries. It involves preparing all raw materials – concrete, bricks, steel – directly at the construction site and then constructing the structure from the ground up, piece by piece. While this method is still widely used, several modern construction technologies have also gained ground over the years. Precast concrete is one such innovation.

Expanding the horizon

Precast concrete is one of the fastest-growing construction technologies today. With stricter government regulations and tighter project deadlines, it has steadily gained ground over traditional construction methods. Its increasing adoption can be attributed to its efficiency, consistency, and speed of execution- qualities that are essential in today’s fast-paced construction environment. “While traditional materials continue to have higher market adoption, precast concrete is emerging as an effective solution – delivering superior quality, reduced construction time, and a significantly lower environmental impact. Precast concrete construction is more than just an alternative – it’s a smarter way to build. Precast concrete can stay relevant and competitive by embracing innovation and sustainability,” says Abhijit Gawde, Head of Marketing & Business Development, Construction business of Godrej Enterprises Group.

Leading the pack

But what exactly is precast concrete, and why is it gaining such momentum?

Precast concrete is a construction product made by casting concrete in a reusable mould or "form," which is then cured in a controlled environment, transported to the construction site, and maneuvered into place. Examples include precast beams and wall panels used in tilt-up construction. In contrast, cast-in-place concrete is poured into site-specific forms and cured directly on-site – often making it more vulnerable to delays caused by weather conditions, labour shortages, or inconsistencies in materials. One of the key advantages of precast concrete lies in the controlled production environment. By manufacturing components in a dedicated precast plant, the process allows for greater quality control, uniformity, and better curing conditions, ensuring the durability and strength of the final product. Speed is another major advantage. Since components are manufactured in advance and delivered ready for installation, construction time is significantly reduced – making precast ideal for projects with tight timelines. Safety and efficiency also improve, as most production happens at ground level, minimizing on-site risks and reducing the reliance on extensive scaffolding or formwork.

Cost-effectiveness comes from the reusability of moulds. In a precast plant, moulds can be used hundreds or even thousands of times, significantly lowering the cost per unit compared to on-site casting. Sustainability is yet another benefit. Precast production generates less material waste and can incorporate eco-friendly materials like lightweight expanded polystyrene (EPS) foam, which improves thermal insulation while reducing overall panel weight. “Unlike traditional construction methods that depend heavily on on-site labour and extended timelines, precast concrete offers several key advantages. It enables faster project completion, as precast elements are manufactured off-site and quickly assembled on-site, minimizing construction delays. It also ensures cost efficiency by reducing labour requirements and minimizing material wastage, which lowers overall costs. Additionally, factory-controlled production allows for consistent quality and structural integrity. From a sustainability perspective, precast construction consumes less water and generates minimal construction waste. To further strengthen its market position, the precast concrete industry must continue focusing on innovation, automation, and increasing awareness of its numerous advantages,” says Krishan Mohan Sharma, Head of India Operations, Vollert India.

Solutions in action

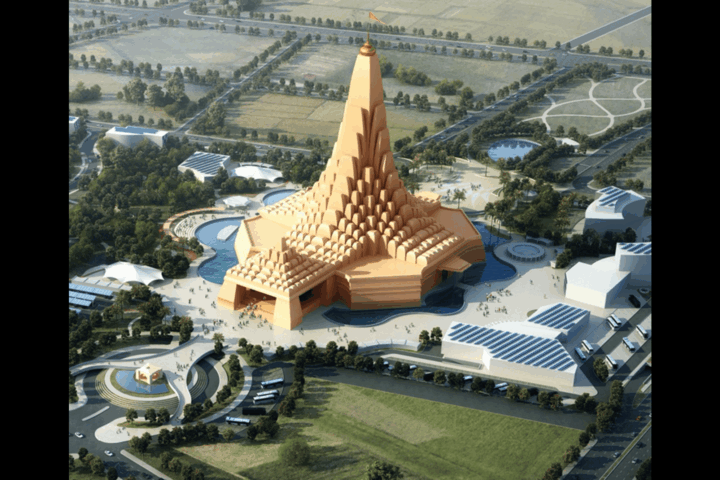

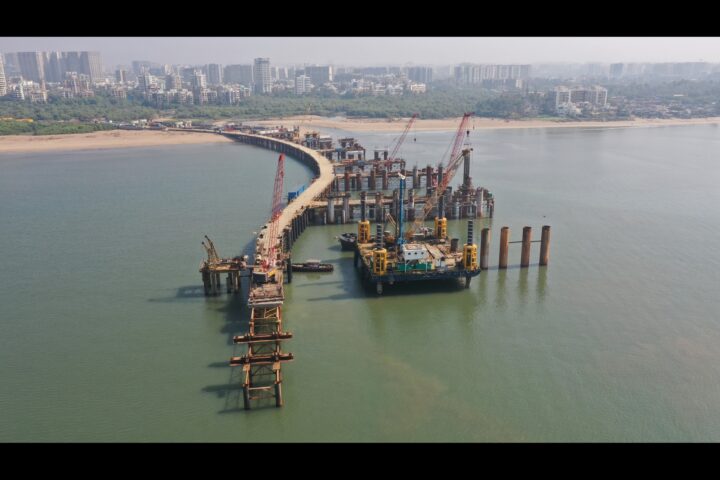

Precast concrete is used in both interior and exterior applications, making it one of the most versatile construction materials available today. Its usage spans a wide range of sectors – including infrastructure, commercial, industrial, and residential projects. In infrastructure, precast concrete is commonly used for highways, flyovers, bridges, tunnels, underpasses, metro rail systems, and railway platforms. Components like girders, crash barriers, culverts, and retaining walls are manufactured offsite and quickly assembled on location, minimizing traffic disruption and project timelines. In high-rise and mid-rise residential or commercial buildings, precast elements such as wall panels, floor slabs, staircases, balconies, columns, and beams offer both structural support and design flexibility. These components can be custom-designed for architectural finishes, insulation needs, and functional integration like plumbing or electrical channels.

Tilt-up construction, typically used for warehouses, industrial sheds, logistics hubs, and data centers, is another major application. Here, large precast wall panels are cast horizontally at the site or in a nearby factory, then tilted vertically and secured in place – offering rapid assembly and significant savings in labour and time. In urban settings, precast is increasingly being used for stormwater drains, manholes, boundary walls, street furniture, and even precast toilets and small modular structures, addressing both infrastructure and urban development goals. Its adaptability also supports innovative and green building practices. Precast can be integrated with thermal insulation, soundproofing, and energy-efficient building systems, making it ideal for modern, sustainable construction.

Unlocking market potential

Whether the priority is speed, structural integrity, cost-efficiency, or design flexibility, precast concrete consistently delivers—making it a preferred choice for developers, engineers, and urban planners alike. It’s no surprise, then, that the market for precast construction in India has witnessed significant growth in recent years. “India’s precast industry is experiencing robust growth, fueled by rapid urbanization, increased infrastructure investment, and significant technological advancements. The rising demand for faster and more cost-effective construction solutions is accelerating the adoption of precast methods across residential, commercial, and industrial sectors. Technological innovations such as automation, AI-driven production planning, and robotics are further enhancing the efficiency and precision of precast manufacturing,” says Krishan Mohan Sharma. According to a report by Grand View Research, the India precast concrete market was valued at USD 6.16 billion in 2023 and is projected to grow at a CAGR of 9.2% from 2024 to 2030. The report attributes this growth to a combination of factors, including exponential population rise, rapid urbanization, large-scale infrastructure development, growing demand for sustainable construction methods, technological advancements, and the pressing need for affordable and efficient residential spaces.

Overcoming challenges

The precast concrete industry, while rapidly evolving, still faces several challenges. One of the primary concerns is the perception of high initial investment, as establishing automated precast plants involves substantial capital expenditure. This issue is gradually being addressed through the availability of industry-specific loans and financial incentives offered by banks and lending institutions. Another persistent challenge is the limited awareness among developers and contractors, many of whom continue to rely on traditional construction methods. The industry leaders and associations are taking proactive steps by conducting awareness drives, technical seminars, and skill development workshops to highlight the efficiency, durability, and long-term value of precast construction.

Precast concrete structures are manufactured in controlled factory environments and then transported to the construction site for assembly. However, transportation costs – which include fuel, labour, warehousing, and handling – can be highly volatile. Any increase in these costs directly impacts the overall project budget, a burden that ultimately falls on the end user. At the site, the installation of precast components requires heavy-duty cranes, which further adds to the operational costs. Handling these components also demands strict safety protocols, as precast elements are typically large and heavy, making them prone to damage if not managed carefully. “Transportation and logistics also pose difficulties, particularly in moving large precast elements to project sites. These issues are being mitigated through optimized supply chain management and the establishment of local manufacturing hubs,” says Krishan Mohan Sharma.

The precast construction industry in India is also experiencing a significant shortage of skilled labor, particularly in areas such as production, handling, and assembly of precast elements. To tackle this issue, targeted training programs and collaborations with technical institutes are being developed to build a skilled workforce and ensure quality standards across the sector. “To enhance the knowledge and skills of labourers, we have recently launched the TUFF Knowledge Series on YouTube. This series currently focuses on training the workforce in best practices for the effective use of Autoclaved Aerated Concrete (AAC) Blocks, covering aspects such as, how AAC Blocks make construction faster and more efficient,” says Abhijit Gawde. Vollert India offers hands-on training and apprenticeship programs focused on precast production and installation, ensuring practical exposure for new entrants. In addition, the company is collaborating with engineering institutes to introduce specialized courses in precast technology, bridging the gap between academia and industry needs. “To further enhance knowledge and adoption, we are conducting nationwide skill development workshops aimed at educating professionals and contractors about modern precast techniques. By investing in workforce development, we aim to create a talent pool capable of driving the precast industry forward,” says Krishan Mohan Sharma.

Scaling new heights

The precast concrete industry in India is witnessing unprecedented momentum, driven by a combination of government policy support, urbanization, infrastructure demand, and sustainability goals. One of the most significant catalysts has been government policies mandating the use of precast technology in infrastructure projects, including metro rail systems, bridges, and highways. The increased preference has, in turn, attracted investment in automated precast plants, fostering innovation, scalability, and widespread adoption across the country. With precast elements produced in controlled environments and assembled on-site, projects benefit from reduced timelines, lower labour costs, and consistent quality. Additionally, the reusability of moulds and reduction in on-site construction waste contribute to a lower carbon footprint, aligning well with India's green building initiatives and climate commitments. The government’s flagship urban development programs such as the Smart Cities Mission, Housing for All, and PMAY (Pradhan Mantri Awas Yojana) have fueled demand for faster and scalable construction technologies. In urban housing, precast technology has proven particularly effective. Rapid economic growth and limited land availability have restricted horizontal development, pushing real estate towards vertical construction. In this scenario, precast has become the go-to solution for building high-rises, especially in metro cities where older structures and slums are being redeveloped into modern, multi-story complexes. In the infrastructure sector, precast technology is helping developers meet stringent deadlines. Components like girders, bridge sections, and pillars are fabricated off-site and transported for quick assembly – saving on labour, reducing waste, and ensuring consistent quality. As India's infrastructure pipeline expands – with major investments in transport, logistics parks, airports, industrial corridors, and smart cities – precast is expected to play a critical role in meeting the demand for timely, efficient construction.

Bright roads ahead

As India accelerates its push toward urban transformation, sustainable infrastructure, and timely project execution, precast concrete is no longer just an alternative – it is becoming a necessity. With strong policy backing, rising private investment, and expanding applications across sectors, the precast industry is set to play an important role in shaping the country's infrastructure landscape.