Interview: V G Sakthikumar, Chairman and Managing Director, SCHWING Stetter India

We will unveil 17 new products that reinforce shift towards alternative fuels, electrification, and advanced precast technology, aligned with India’s Net-Zero and Aatma Nirbhar Bharat vision

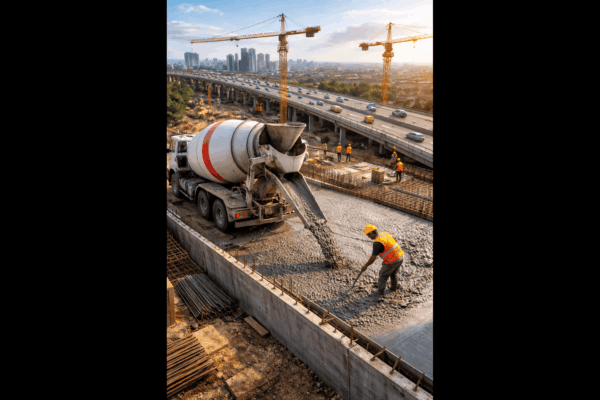

Concrete plays a critical role in every large infrastructure project. What shifts are you seeing in the type or scale of equipment being preferred today?

The primary shifts SCHWING Stetter India (SSI) observes are driven by massive government-led initiatives like the National Infrastructure Pipeline, leading to a demand for equipment that can deliver high-volume, high-quality concrete with improved productivity. There is a pronounced shift towards higher capacity batching plants and larger-capacity transit mixers (eg, 9-12 Cubic meter truck mixers) to meet the sheer volume requirements of major projects like expressways, metro rail, and large tunnels. For projects that are spread out (eg, roads, canals), the preference is for Mobile Batching Plants (like the M 21 Z or M 30 Z with Pan Mixers) which offer quick erection, dismantling, and re-location, reducing cycle time between sites. For high-rise and tunnelling projects, the demand for Truck Mounted Concrete Pumps (eg, the S 43 SX III or S36X and the new launch S56 SXF) and specialized Stationary Pumps (like the SP 8800 or SP 4507 which are high-pressure pumps) remains strong. There is a growing focus on high-reach and easy-to-manoeuvre placing booms. SSI is positioning itself as a comprehensive infrastructure partner by expanding beyond core concrete equipment into segments like crushers (under material handling) and pre cast solutions, indicating a customer preference for a single-source equipment provider.

How is your company approaching the transition to electric and hybrid concrete equipment, and what challenges do you see in scaling this technology in India’s operating conditions?

SSI is accelerating its shift towards electric and hybrid concrete equipment, moving swiftly from concept to commercial launch to support India’s decarbonisation and modern infrastructure goals. The TSR 30.1 fully electric Shotcrete Pump is already serving tunnel and underground projects requiring zero-emission operations. The upcoming S 36 hybrid Boom Pump, fully electric Truck Mixers, and Stationary Pumps further demonstrate SSI’s commitment to full-fleet electrification. For customers not yet ready for complete electric adoption, SSI continues to offer Biodiesel (B7)-compatible equipment as an immediate, lower-carbon alternative. All new machines are equipped with IoT and telematics for real-time monitoring and predictive maintenance, ensuring optimal battery performance and uptime.

The key challenges in scaling electric and hybrid concrete equipment include the absence of robust, standardised charging infrastructure across India’s remote and widely dispersed construction sites; the high upfront cost of large battery packs and long-term battery replacement concerns affecting Total Cost of Ownership; unreliable grid supply that limits fast charging for high-output equipment; and battery weight constraints on electric truck mixers, which can reduce legal payload capacity and operational range – critical factors for RMC logistics.

With the push toward Make in India and supply chain resilience, how are you localising key components such as batteries, hydraulics, or electronics, and what impact has this had on costs and delivery timelines?

Localization has been central to our strategy for over two decades – well before the ‘Make in India’ initiative—and has strengthened our supply chain resilience and cost competitiveness. By developing a robust local vendor base and leveraging our Global Manufacturing Hub (GMH) in Cheyyar, we have achieved high localisation across major structural components such as frames, bins, and mixer drums, sharply reducing costs and cutting delivery timelines by avoiding international logistics. For hydraulic systems, we localise non-precision parts while continuing to import specialised, high-precision components to maintain performance and reliability. The main challenge now lies in localising advanced electronics, chips, and high-density battery cells required for electric and hybrid equipment, as global supply chain complexities keep us dependent on international suppliers and increase costs. Despite this, our broad localisation success has improved parts availability, strengthened after-sales service, and reduced maintenance times. The GMH in Cheyyar anchors this effort, enabling large-scale domestic production, Industry 4.0-compliant quality, and positioning SSI as a global export hub for the Schwing group.

Telematics and IoT are redefining fleet management. How are you integrating these technologies into your machines, and how do you see data-driven insights influencing future product development?

SSI’s telematics framework – IoT In, IoT Ready, and IoT Abled – provides real-time monitoring and control across its equipment range. It tracks production parameters such as concrete volume, batch cycle times, mix consistency (via MCI 550), and full material traceability to ensure consistent quality. Mobile plants benefit from GPS-based location tracking, while critical performance data such as hydraulic pressure, temperature, pump hours, stroke count, and actual output enable accurate machine health assessment. VECTOR-based remote diagnostics deliver instant alerts and faster troubleshooting, improving uptime. In RMC logistics, telematics monitors vehicle movement, drum RPM and status, rotation counts, maintenance reminders, and battery voltage through a CAN-based controller, ensuring efficient fleet and delivery management. These data streams feed directly into SSI’s R&D. By analysing fuel use, hydraulic pressure patterns, wear part behaviour, and component stress, SSI advances from scheduled to predictive maintenance. Insights are used to optimise engines, hydraulics, and battery performance for upcoming EV/hybrid models like the S 36 Hybrid Boom Pump, while improving durability and safety through smarter control systems. Ultimately, this data-driven approach enables continuous product improvement and lays the foundation for future AI-driven, self-optimising machines aligned with real-world customer needs.

The industry is moving toward equipment-as-a-service and leasing models. How is your company responding to this trend, and what advantages does it offer both manufacturers and contractors?

SSI is strategically responding to the industry shift towards Equipment-as-a-Service (EaaS) and leasing models by broadening its financial and service offerings, recognizing that contractors increasingly prioritize operational flexibility over outright ownership. While direct manufacturer-owned leasing is emerging, SSI’s primary response involves establishing strong partnerships with leading financial institutions and banks and Non-Banking Financial Companies (NBFCs). These alliances allow SSI to offer customers highly customized financial solutions, including commercial equipment loans and easy monthly repayment plans, which function similarly to a finance lease by lowering the initial capital outlay and spreading the cost. Furthermore, SSI directly supports the EaaS model through its robust Operation and Maintenance (O&M) and Annual Maintenance Contract (AMC) services, which are crucial for success in leasing, as these transfer the technical and reliability risk to SSI, the equipment expert.

Sustainability is becoming central to construction. What initiatives – such as eco-friendly manufacturing, energy-efficient equipment, or cleaner power options like hybrid and electric machines – is your company taking to align with India’s net-zero goals?

SSI is strongly aligned with India’s Net-Zero 2070 goals through a comprehensive sustainability strategy focused on circularity, clean power, and green manufacturing. The company promotes a circular economy with its Concrete Recycling Plants (RA series) and C&D Waste Crushers, enabling reuse of the 750 million tonnes of concrete waste generated annually and reducing reliance on fresh aggregates. SSI is rapidly shifting toward clean-power equipment, with the TSR 30.1 fully electric Shotcrete Pump already launched and upcoming introductions of the S 36 Hybrid Boom Pump and fully electric Truck Mixers and Stationary Pumps. Energy efficiency is enhanced through optimised hydraulics, low-TCO design, and IoT-based performance monitoring that improves fuel and battery consumption. At the manufacturing level, the Industry 4.0-enabled Global Manufacturing Hub in Cheyyar runs on energy-efficient processes supported by a 1 MW solar power system. SSI’s #GoGreenwithSchwing campaign furthers its sustainability vision through large-scale reforestation drives, while collaborations with IIT Madras on low-carbon lean concrete reinforce its contribution to long-term decarbonisation.

What new products, live demos, or key initiatives can visitors look forward to from your company at Excon 2025?

At Excon 2025, Schwing Stetter India will present an extensive line-up of innovations under the theme “Driving India’s Infrastructure with Sustainable & Next-Gen Concreting Solutions” with the tagline “Engineering Future.” Located at the Orange Lot, OD 27 and Hall 1 – Lower Level, D 57, the company will unveil 17 new products that reinforce its shift towards alternative fuels, electrification, and advanced precast technology, aligned with India’s Net-Zero and Aatma Nirbhar Bharat vision. Visitors can look forward to a new era of sustainable transit mixers, including an 8 cu.m fully electric truck mixer, a range of CNG-powered mixers, and an advanced hybrid boom pump designed for cleaner, quieter operations. The showcase will also feature a high-efficiency VFD stationary pump with dynamic power optimisation and an expanded portfolio of Mar Truder precast solutions aimed at accelerating high-quality, standardised construction. In addition, Schwing Stetter will present its full range of crushing and recycling equipment to support aggregate production and promote circular economy practices through C&D waste processing.

Tags