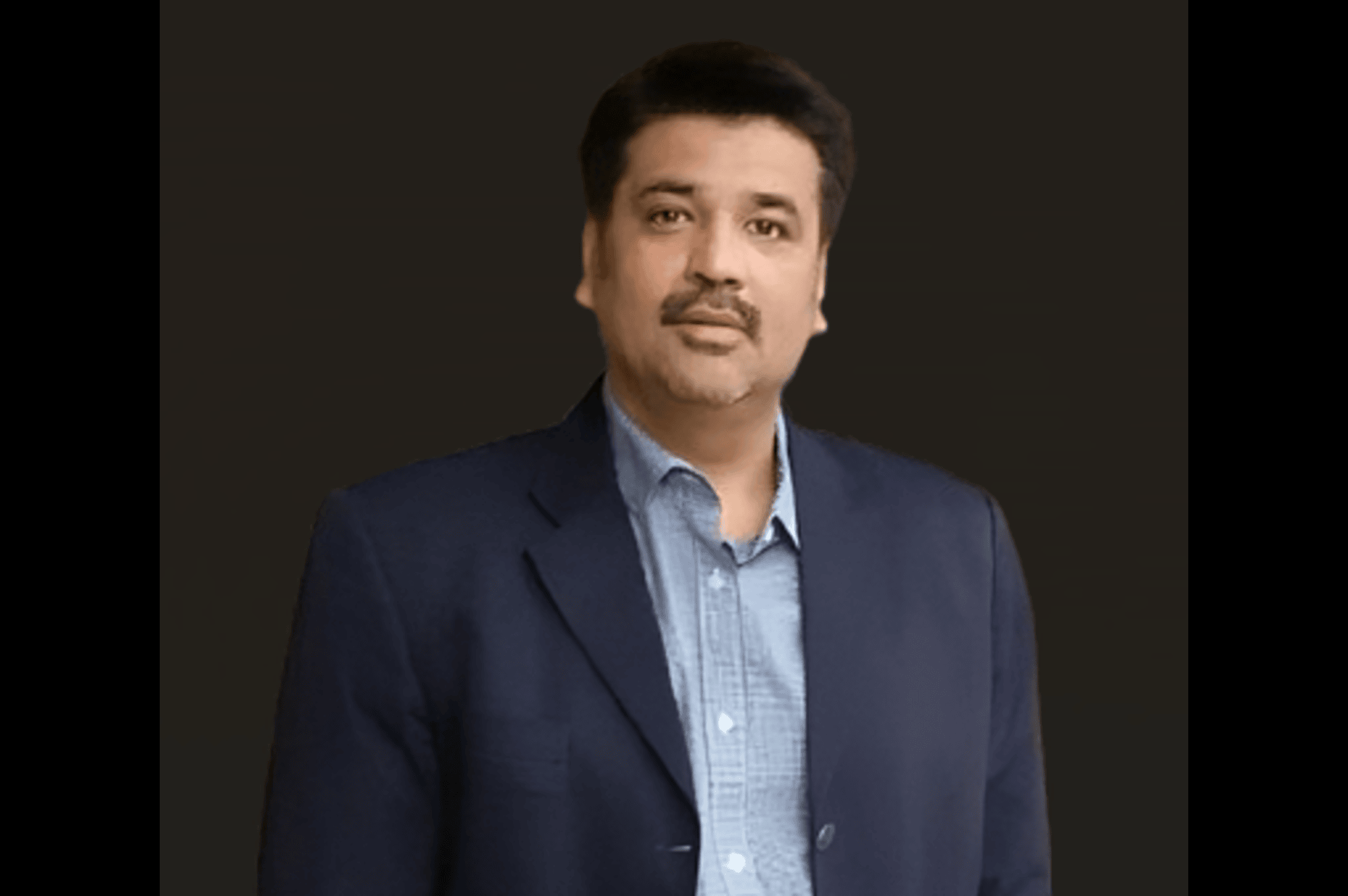

Interview: Ritesh Puranik, Chief General Manager, OTR Tires (Mining & Solutions), Bridgestone India

Bridgestone I Track has proven abilities of improving tyre performance, mine site safety & productivity while resulting in customer savings

How is Bridgestone driving value creation and sustainability in the off-the-road (OTR) tyre segment for the mining industry?

At Bridgestone, our goal, as a sustainable solutions company, is to co-create with our customers to AMPLIFY VALUE through our products, solutions, and expertise that helps deliver our business aspirations. Bridgestone Off-The-Road offers a robust lineup of innovative tyres engineered with compounds suited for various surfaces and applications. Bridgestone OTR tyres are designed with intelligent technologies to help customers in their quest for reliable performance and improved productivity. Designed with smart tech inside for hard work outside, Bridgestone Master core tyres are built to take on mining applications – with innovative core technology and proprietary design improvements for enhanced performance and lasting wear, enabling customers to discover up to more durability, faster speeds and increased load capacity. Bridgestone, I Track – Global Next Generation Comprehensive Mining Monitoring System delivers customers real time data regarding live temperature, pressure of tires along with vehicle position, speed and accelerometer data which helps our customers make data driven decisions & improve their operational productivity.

How is Bridgestone supporting the transformation of India’s mining sector through its advanced product and solution offerings?

The mining industry is constantly evolving, and the Indian mining landscape is undergoing a shift with digitalization and adoption of new technologies. With rising demand for coal & critical minerals, there is a stress on mines to extract more. Our products are focussed on improving mining productivity, while adopting the highest levels of safety for the operations. As Bridgestone’s best-in-class mining tire, Master Core is the foundation of the company’s mining solutions business. The tire is engineered for ultra-high durability, based on a combination of unique technologies that include a new type of steel cord and other advanced materials, structure and process engineering. The tyres can also be customized to various mine sites and operations. Master Core tyres can be optimized for a number of performance attributes including faster speeds, increased payload and maximized uptime. Our Next Generation Mining Solution – Bridgestone I Track, helps customer make data driven decisions with 24X7 live data about important tyre parameters such as temperature and pressure, combined with vehicle operational data such as GPS position, mine site Geo Fence & Accelerometer data which provides insights into haul road conditions, driver behaviour and downtime, all of which enables customer to optimize their operations and MOVE MORE WITH LESS.

The tyre industry has made significant strides with digital technologies, including IoT sensors, telematics, AI, and digital tyre monitoring systems. How are these features integrated into your tyres, and how do they enhance performance, safety, and operational efficiency?

The use of digital technologies has become vital in analysing tyre performance, and the mining segment is no different. Bridgestone I Track is the leading IoT enabled TPMS solution for the ultra-large class mining dumpers which provides real time data on tyre temperatures, pressures & insights into haul road conditions. We make use of hardware devices such as sensors, receivers and processors which collect & analyse vital tyre and vehicle data which is accessible to customers over a webpage Dashboard. Bridgestone I Track has proven abilities of improving tyre performance, mine site safety & productivity while resulting in customer savings. Bridgestone iTrack also provides the customer with detailed KPI reports and data insights through analytics. Our system can also be integrated with other solutions which the customer may be using, such as mine dispatch systems, OEM provided systems or other 3rd party systems. Bridgestone iTrack, with proven integration capability & highest level of sensor/system availability, is the most suitable & reliable partner for solutions project. In addition, by continuously feeding back data and knowledge obtained by the company’s solutions offering, Bridgestone will further improve its product portfolio, expand its service offering and strengthen the company’s tyre wear and durability prediction technology. This will enable Bridgestone to continue to provide even greater value to society and customers.

Sustainability is becoming a key focus. How are your tyres designed to support sustainability, efficiency, and reduced environmental impact in mining operations?

With the mission of “Serving Society with Superior Quality”, Bridgestone since its foundation in 1931 has continued to grow by turning various changes into opportunities. Based on our mission and guided by our vision – “Toward 2050, Bridgestone continues to provide social value and customer value as a sustainable solutions company”- we are accelerating our transformation, with our corporate commitment, the Bridgestone E8 Commitment, as the axis of the Bridgestone way of value creation that embodies our vision and mission. Bridgestone is striving to realize a sustainable society and simultaneously build a foundation of sustainable value creation across the value chain. Our sustainable procurement initiatives are grounded in our Global Sustainable Procurement Policy and align with our goal of using 100% sustainable materials by 2050. Bridgestone is focussing on sustainable procurement of natural rubber, a key raw material in tyre manufacturing and an essential renewable resource for producing high quality tyres. However, as demand for natural rubber continues to rise, it is beginning to be viewed as a threat to global deforestation. Therefore, efforts towards sustainability of natural rubber are recognized as crucial management issue for business continuity. We have proactively collaborated with our suppliers to enhance supply chain traceability to ensure governance and compliance to ever-changing business conditions. Moving forward, we will continue to build fair, “win-win” partnerships through diligent and steady efforts practicing Genbutsu-Genba (Respect for Being On-Site) that ultimately results in sustainable use of natural rubber. We remain dedicated to creating sustainable value through growth with quality.

With the global economy slowing and supply chains under pressure, what financing solutions do you offer? Are you offering any financial assistance or support to customers?

Our cornerstone for sustainable value creation is “creating good business quality.” In today’s turbulent business environment, responding to change and delivering value sustainably requires enhancing customer value through our offerings – ranging from Dan-Totsu products to digital transformation that fuses digital and physical capabilities, including the strong craftsperson skills we have cultivated on-site. Thorough planning and clear visibility into customer demand enable us to respond effectively to fluctuating demand cycles, maintaining only the necessary inventory of SKUs. Our strong Distributor Network in key mining regions ensures timely fulfilment of customer demands

Going forward, how do you see your engagement with the Indian mining industry?

The mining sector is on the threshold of a new era in tyre management, driven by digital innovations. The integration of AI, data analytics, and advanced sensor technology is transforming the way tyres are monitored and maintained, promising significant improvements in safety, efficiency, and environmental impact. Telematics and fleet management software play a pivotal role in modernising mining tyre safety. These systems collect data from various sensors embedded in mining vehicles and tyres, transmitting it to a central system where fleet managers can access it remotely. With this data, fleet managers can monitor tyre pressure, wear, and temperature, as well as other operational metrics in real time.

Bridgestone, as a sustainable solutions company, will be central to that transformation through Dan-Totsu tyres, next-generation mining solutions, and on-field expertise that help customers MOVE MORE WITH LESS. Our aim is to enhance customer value by increasing operational efficiency and maximizing economic returns, while generating social benefits through lower CO2 emissions and improved resource productivity. Bridgestone has also designed upskilling initiatives training tyre for people who work in the mining area. Together these efforts help build a Bridgestone-led mobility ecosystem.

Tags