Interview: Ravi Todi, Managing Director, BTL EPC

The decade ahead is poised to unlock unprecedented growth and usher in a profound transformation across the mining sector. We are committed to playing a catalytic role in this evolution, says Ravi Todi, Managing Director of BTL EPC, in an interaction with EPC World

From underground mining equipment to large-scale EPC projects across mining, power, and ports — how has BTL EPC built its expertise and strengthened its market presence over the decades?

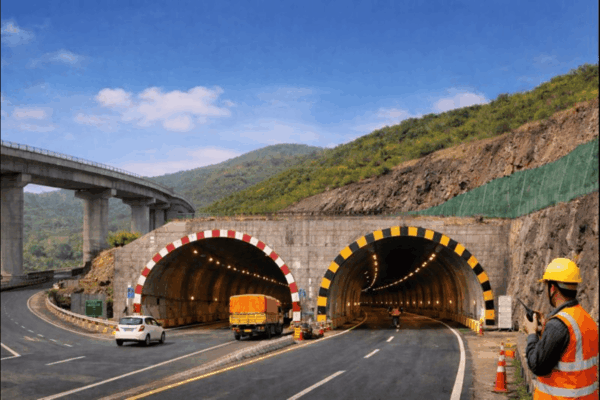

BTL EPC, with a legacy of nearly six decades, began its journey as a small tool manufacturing company and has since evolved into a diversified engineering, procurement and construction (EPC) organisation with a strong footprint across mining, power and material handling. Our first major breakthrough came in underground mining, where we supplied complete conveyor systems — motors, gearboxes and structural components — to leading mining subsidiaries across India. Over time, we became one of the country’s leading suppliers of underground conveyor equipment, serving clients such as JMS Mining, Gayatri Projects and Gainwell. Leveraging this foundation, we expanded into power integration and bulk material handling, covering coal, ash, coke and fertilisers. We have executed several coal and ash handling projects for BHEL, NTPC and Adani, and successfully completed assignments for HURL at Sindri and Barauni, including specialised bagging plants.

To date, we have delivered more than 50 coal-handling projects nationwide and continue to be a preferred partner for BHEL and NTPC. In mining, one of our flagship projects is the NTPC Pakri mines, where we executed a 3 km conveyor system connecting the mine to the rapid loading system and railway siding. Similar projects are currently under execution at NTPC’s Talaipalli and Kerandari mines. Mining services remain central to our operations. Our present order book stands at around ₹3,000 crore and includes major projects for TSGENCO, Adani, TANGEDCO, NTPC, Haldia Dock, KRIBHCO, HURL. Beyond mining, we are broadening our presence in port infrastructure with a new project at Haldia Port, and in coal chemical plants — all delivered under the EPC model. A major strength that sets BTL EPC apart is our in-house capability. With more than 100 designers and engineers across civil, structural, electrical and dust-separation domains, we deliver fully integrated, end-to-end solutions without external dependency. We are also proud to have commenced work with the Adani Group on the coal and ash handling plants at Adani Raigarh. This project marks another significant milestone in our journey, and we are confident of executing it with the same reliability and commitment that define BTL EPC.

With the government’s strong push for mining and rising demand for power, how do you assess the sector’s growth trajectory over the next few years?

The government is highly bullish on the mining sector and is backing it with strong policy support, especially as power demand continues to rise. With the expansion of the power sector, the requirement for coal and other raw materials is increasing rapidly, giving a substantial boost to mining activities nationwide. Coal India, for example, has significantly scaled up its production targets and is investing heavily in expanding underground mining. NTPC is also moving aggressively to develop and mechanise its captive mines. The future of mining in India clearly lies in mechanisation, with technologies such as highwall and longwall mining gaining wide acceptance. Another encouraging trend is the rising participation of private players through the Mine Developer and Operator (MDO) model, which is bringing in greater efficiency, advanced technology and much-needed investment into the sector. Given these developments, we at BTL EPC are very optimistic about the next 3–5 years. We see robust opportunities in mining infrastructure and mechanised systems, and we are gearing our capabilities to meet this demand. With our proven expertise in conveyor systems, bulk material handling and end-to-end EPC delivery, we are well positioned to support India’s mining expansion. The coming decade promises strong growth and significant transformation for the mining sector and we aim to be an active contributor to that progress.

BTL EPC has been expanding its manufacturing capabilities across several locations. How is this supporting your current India-centric strategy and global ambitions?

At present, there is ample opportunity within India, and our focus remains on consolidating our position in the domestic market. We have not yet ventured into international markets, but expanding our global footprint is certainly on our long-term roadmap. BTL EPC has a strong manufacturing base with five facilities – three in Kolkata, one in Durgapur, and one in Kharagpur. These facilities are being continuously upgraded to enhance our in-house capabilities. We are now producing a wide range of specialised mining equipment, including paddle feeders, gearboxes for underground mining, pulleys, idlers, and structural fabrications. Our strategy is to maximise in-house manufacturing to support our EPC operations. This not only ensures better quality control and faster project execution but also gives us a competitive advantage in terms of cost and delivery. With these capabilities in place, we are confident that when the time is right, we will be well positioned to enter overseas markets and deliver world-class EPC solutions globally.

Is BTL EPC exploring joint ventures or strategic partnerships to support larger and more complex projects?

We are definitely open to joint ventures and partnerships. Many large-scale projects today require collaboration – it’s not possible to execute everything independently. As we move towards larger and more complex assignments, particularly in the Balance of Plant (BOP) segment, partnerships are becoming an integral part of our strategy. We are already in discussions with a few prospective partners, both domestic and international, to jointly bid for major BOP projects. These projects typically cover civil, structural, and electrical works, and in such cases, combining expertise is essential to meet scale, technology, and qualification requirements. In addition, we are exploring technological joint ventures for certain specialised equipment and systems. Such collaborations will allow us to integrate advanced technologies, enhance our execution capabilities, and expand our footprint into new domains. We see partnerships as a key enabler for our next phase of growth.

What message would you like to give to young engineers who are considering a career in the EPC sector?

The message to young engineers is, there is tremendous opportunity for young engineers in the EPC and power infrastructure sectors today. After a brief slowdown a few years ago, the industry has revived strongly. The government’s renewed focus on power and infrastructure, along with major investments from players like BHEL, NTPC, and Adani, has created a vibrant ecosystem for growth. Similarly, the steel sector is witnessing massive expansions – with projects worth thousands of crores underway at plants in Durgapur, Rourkela, Burnpur, and others. This is the right time for young mechanical, electrical, and civil engineers to enter and make their mark in this industry. For too long, talent has been drawn mainly toward IT and software, but engineering and infrastructure now offer equally rewarding and dynamic career paths.

Tags