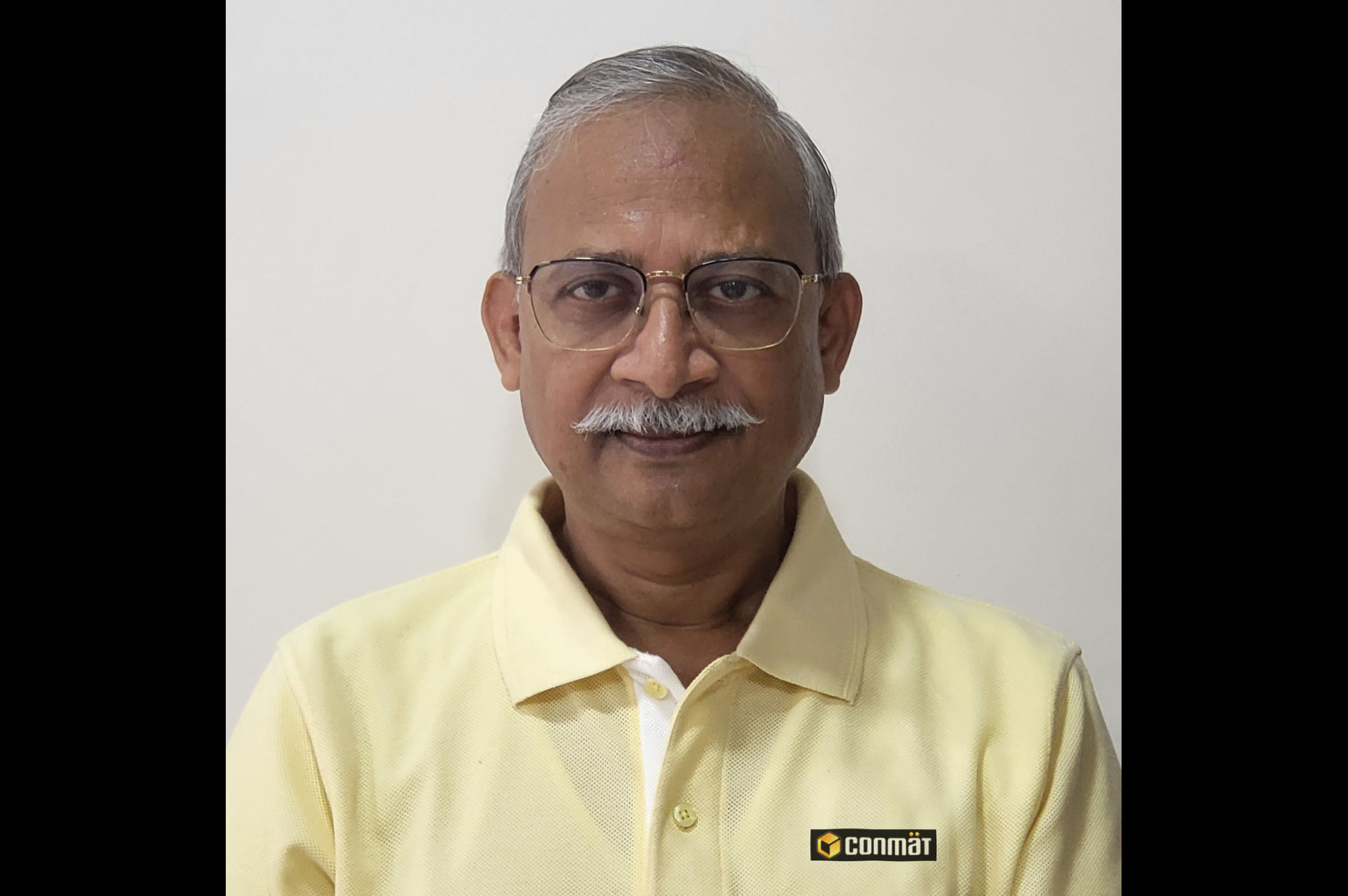

Interview: Prem Raj Keshyep, Founder & CMD of Conmat Heavy Industries

How central is R&D to Conmat’s long-term growth and innovation strategy?

Research and development lies at the core of Conmat’s future strategy. The company has set up a dedicated R&D centre to design and manufacture machines indigenously, demonstrating that world-class innovation can emerge from India. While the development of electric and sustainable machinery involves significant technical complexity and investment, Conmat sees this as both a strategic imperative and a social responsibility, closely aligned with global sustainability objectives. Platforms like EXCON provide an ideal opportunity to showcase these innovations, engage directly with customers, and exchange insights with industry stakeholders. Through sustained investment in R&D, Conmat aims to elevate Indian manufacturers from being perceived as labour-driven players to recognised technology leaders, while contributing to a robust ecosystem for the next decade of infrastructure development.

How is Conmat expanding its export footprint from India, and what role do its manufacturing facilities play in supporting this growth, including the showcase at EXCON?

Conmat has already established a strong global presence, exporting to more than 25 countries, with its concrete equipment gaining wide acceptance and nearly 2,000 machines operating overseas. Building on this proven credibility, the company is now extending its export strategy to include earthmoving equipment as well. At present, earthmoving machines are manufactured at the Baroda facility; however, Conmat is making a significant investment in a new dedicated plant for its earthmoving range. This expansion underlines Conmat’s long-term commitment to strengthening its manufacturing base in India and scaling up exports, a strategy that is prominently showcased at platforms such as EXCON.

Which segment do you see as the strongest demand driver in the industry right now?

Conmat follows a strategy of diversification rather than relying on a single segment. Its product portfolio spans multiple sectors—including infrastructure, ports and bridges, factories, residential projects, and the RMC sector. This approach ensures that when one sector slows, others continue to support the business, allowing the company to navigate market fluctuations effectively. By maintaining a diverse customer base and application areas, Conmat has remained resilient and ready to handle challenging market conditions.

Looking at macroeconomic factors such as interest rates, fiscal spending, and exchange rates, which of these do you think is having the most impact on the industry?

Certainly, there is a direct impact from these macro factors—tariff restrictions, geopolitical tensions, and exchange rate fluctuations all affect the industry. However, at Conmat, we view challenges as opportunities. For instance, when external conditions are tough, we explore new avenues such as exports, indigenous development, or expanding our product range. Diversifying from concrete equipment into earthmoving machinery is a strategic move to strengthen the organisation internally, ensuring that external factors have minimal effect. The core philosophy is simple: if your internal capabilities are robust, you can navigate any external challenge. Tough times, in fact, are ideal for innovation. When markets are booming, there is little room for development. But during challenging periods, creativity and innovation naturally emerge, improving overall capability. Periodic industry slowdowns, while difficult, bring out the innovator in us – and that is precisely what Conmat is leveraging to build resilience and drive growth.

Digitalization and telematics are being widely discussed across the CE industry. Could you shed some light on Conmat’s approach in this area?

Conmat has been a pioneer in digitalization long before it became a buzzword. As early as 2009, we were using digital prototyping to design and develop machines on computers, testing them for lifecycle, maintainability, and fatigue life. Every product undergoes complete simulation before launch, enabling us to bring products to market rapidly and efficiently. Regarding IoT and technological advancements, we have integrated IoT into our operations for many years. Artificial intelligence has also been embedded in our batching plants for nearly a decade. AI enables precise control over critical parameters—cement, aggregates, water, and temperature—automatically adjusting based on material properties and environmental conditions. This long-standing adoption of digital technologies and AI gives us a significant edge in efficiency, accuracy, and product reliability, well ahead of current industry trends.

With the growing focus on electric and low-emission CE, how is Conmat addressing challenges related to charging and refueling?

Battery charging is indeed a major challenge for electric machinery. To address this, we are adopting a technology called range extension, which uses a diesel engine to charge a spare battery, thereby extending the operational time of the equipment. While many rely on cutting-edge technologies developed abroad, we believe that as an Indian manufacturer, it’s important to simplify and adapt solutions for our context. By combining innovative approaches with proven, time-tested principles, we are developing practical and implementable solutions for electric equipment.

Looking ahead three to five years, what major shifts do you foresee in terms of technology or business models in the CE industry?

Technology adoption is critical – companies that fail to adapt will be left behind. Similarly, business models must evolve. The market is no longer manufacturer-driven; it is increasingly customer-centric. Customers today are informed, knowledgeable, and demand solutions tailored to their needs. To succeed, manufacturers must be agile, listen to their customers, and position themselves as technology providers rather than just sellers. Adapting to these changes is no longer optional – it’s essential for survival.

Tags