Interview: Mehul Parikh, President – Customer Service Group, Pidilite Industries

We want leak-free, heat-free and energy-efficient structures to become the norm across the country

Pidilite has been a pioneer in construction chemicals and waterproofing solutions for decades. What prompted the launch of Pidilite Professional Solutions (PPS), and what gap in the market is it designed to fill?

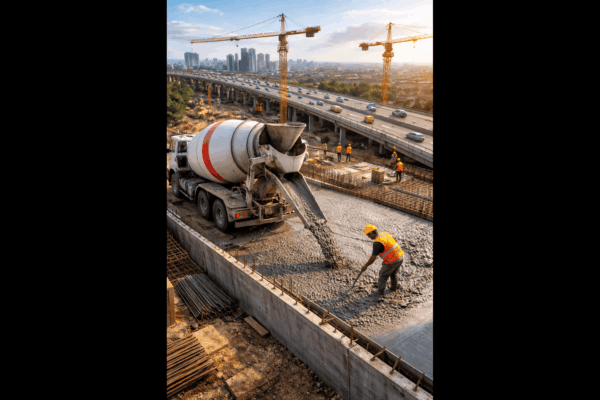

Over the years, we have observed a consistent challenge in the construction ecosystem. While construction materials and technologies have evolved significantly, many architects, developers and civil contractors still struggle with two critical aspects: selecting the right, fit-for-purpose solution and ensuring its correct application. Apart from the errors in application, most failures in waterproofing or specialty construction chemicals such as floor coatings or complex tilling applications often can be traced back to an error in system selection, or an assumption that a solution used in one project can be replicated in another – when in reality, every project has distinct functional, structural and environmental requirements. For example, the solution needed for a hospital may be very different from that for a five-star hotel or a residential tower. This gap – between available technologies and the ability to select and apply them correctly – is what prompted the creation of Pidilite Professional Solutions (PPS). PPS was conceptualised as an integrated, end-to-end support platform for stakeholders across the value chain, whether the requirement is waterproofing, flooring, tile and stone care, external façade protection or structural rehabilitation. Through PPS, we work closely with real estate developers, architects, structural consultants and contractors right from the design and conceptualisation stage to define the most appropriate system solution for the project. By bringing together diagnostics, material science and technical application expertise under one umbrella, PPS enables a shift from a product-centric approach to a holistic, solution-led ecosystem. The aim is simple: to ensure long-term durability, leak-free performance and total peace of mind.

How Pidilite Professional Solutions aligns with India’s growing emphasis on sustainable and high-performance construction and what unique value does it bring to the construction fraternity?

India’s climate realities are changing rapidly, and this has a direct impact on how we must design and build our structures. Recent climate reports show a 1.4x increase in extreme rainfall events in just the past five years, alongside an unprecedented rise in out-of-season rain. At the same time, India has experienced a 15-fold increase in extreme heat days over the past three decades. These shifts – erratic monsoons, extended rainfall, and severe heat – demand a transition toward high-performance, durable and sustainable construction systems. Sustainability today goes far beyond simply using ‘green’ materials. It encompasses resource efficiency, lifecycle durability, reduced maintenance needs and minimal environmental footprint. This is where PPS creates significant value. PPS focuses on system solutions that minimise rework, reduce material wastage and shorten application time to speed up construction across seasons, all while enhancing long-term structural durability. For example, our recently launched primer-less roof waterproofing system lowers material consumption by reducing the number of layers needed and their ability to bond to multiple substrates including PVC enables fool proof detailing at penetrations, simplifying application for ensuring successful outcomes. Our new age solutions not only require less labour reducing the challenges faced in getting sufficient skilled manpower on sites, but also have lower VOC content and support faster, more efficient construction. In addition, PPS helps developers meet and exceed green-building compliance requirements by offering integrated, energy-efficient systems – for instance, Dr. Fixit LEC for roof waterproofing with insulation, and WALACE façade systems that combine insulation, waterproofing and finishing in one integrated solution. These systems not only support sustainability certifications but also ensure that buildings remain durable, leak-free and resource-efficient throughout their lifecycle. In essence, PPS aligns perfectly with India’s growing emphasis on sustainable and high-performance construction by providing end-to-end, science-backed, application-driven solutions that improve durability, reduce environmental impact and future-proof our built environment.

The concept of integrated project solutions is gaining traction. How does PPS plan to offer a one-stop approach – from design consultation to execution – in areas such as waterproofing, flooring, and structural rehabilitation?

Our PPS model is built entirely around the principle of integration. Instead of treating waterproofing, flooring or structural rehabilitation as isolated activities, PPS brings every critical stage of a project under a unified, holistic technical framework. We engage with clients through five key pillars: diagnostics, design support, innovation in products and technologies, on-site technical audits, and trained application and execution support. Together, these create a true one-stop solution – right from project conceptualisation to final delivery. It begins with detailed site diagnostics. Using advanced tools, we identify root causes and project-specific requirements early, enabling us to prescribe the right system rather than generic solutions. This is followed by close collaboration with architects and structural consultants during the design stage, where our technical experts help incorporate accurate, performance-based specifications into project documents.

For execution, PPS offers a robust delivery ecosystem. Our in-house subsidiary Nina Percept handles large-project waterproofing, while our nationwide network of certified and trained applicators supports flooring, tile and stone care, façade solutions and more. This ensures precision, consistency and adherence to best practices across all solution categories. To further strengthen integration, we have digitised much of the process. Our SAATHI digital platform enables on-site training, periodic inspections and SOP-based quality checks, giving project teams real-time visibility and governance over application standards. Through this seamless integration – from diagnostics and design consultation to certified application and digital project tracking – PPS ensures higher performance, faster execution, reduced long-term maintenance costs and sustainable, durable structures. This is the foundation of our one-stop, end-to-end project solutions approach.

The construction chemicals industry is witnessing rapid technological evolution. What are the latest innovations in waterproofing and construction chemicals that Pidilite is introducing through PPS?

The rapid shifts in climate patterns, rising temperatures and the shortage of skilled labour are driving the need for simplified yet high-performance construction solutions. At PPS, our innovation philosophy is centred on exactly this – developing systems that are easier to apply, reduce layers and time, and deliver superior long-term performance. One of our key innovations is Dr. Fixit Wonderproof 100, a hybrid PU liquid-applied, primer-less waterproofing system designed especially for roofs in new construction and renovation projects. It can be applied directly over existing roof surfaces – including old tile finishes like china mosaic – and bonds seamlessly to PVC, metal and other substrates without the need for primers or separate detailing products and is rainproof in one hour of application. This makes it an industry-first solution for fast, reliable refurbishment of roofs. We have also introduced Dr Fixit Flexi PU 500GC, another hybrid PU based liquid-applied system that can be applied even over damp surfaces. This is a major advantage during monsoons or in basement and podium applications where substrates often have higher moisture content. By eliminating delays caused by having to wait for typical drying times, the product addresses a critical pain point for contractors significantly speeding up the overall construction. In tiling, our ROFF range now includes specialised adhesives for large-format tiles and exterior cladding, which require significantly higher bonding strength. As architects increasingly shift to bigger tiles and complex façade designs, these high-performance adhesives ensure better stability, reduced failures and faster installation. We are also developing advanced flexible coatings and hybrid polymer systems to support the growing trend of larger floor plates in commercial, institutional and premium residential projects. These structures experience higher thermal movement, and our coatings are engineered to withstand greater expansion–contraction cycles, especially in podium decks with mixed-use loads like parking, landscaping or recreational spaces. On the façade and roofing side, we are integrating insulation, waterproofing and energy-efficient finishes into single systems through our WalAce and Deco InsuPanel solutions. This not only improves thermal comfort but also aligns with India’s push to reduce urban heat island effects. For rooftop sustainability, we now offer robust solutions for roof gardens – systems designed to give designers confidence that green roofs can be executed safely without long-term leakage risks. These innovations – across waterproofing, tiling, façade systems and energy-efficient solutions – reflect PPS’s commitment to delivering solutions that simplify application, minimise waste and rework, accelerate construction timelines and ensure long-lasting, high-performance structures.

Sustainability has become a key driver in the construction ecosystem. How is PPS helping clients meet green building standards and reduce carbon footprints through environmentally friendly formulations?

Sustainability for us begins right at the system design stage. Every layer, material and application process in a PPS solution is evaluated for its environmental impact. We are developing formulations that reduce chemical consumption – such as systems that eliminate the need for primers – and extend maintenance cycles. Both aspects directly lower the lifecycle carbon footprint of a project and help clients meet green building standards. At the regulatory level, new standards like the Energy Conservation and Sustainability Building Code (ECSBC), introduced in 2024, are becoming increasingly important as states begin adopting them. In line with this, we have integrated insulation and waterproofing in systems such as Dr. Fixit LEC (low energy consumption). This enables buildings to meet the prescribed U-value requirements and improves overall energy efficiency providing long term cost benefits. Our product portfolio also complies with global norms for low VOC content and eco-friendly formulations. We align closely with Indian green rating frameworks such as GRIHA to ensure that our solutions support clients in achieving their sustainability targets. Overall, whether it is through optimised formulations, integrated systems, or compliance with advanced codes and rating frameworks, PPS is focused on helping customers adopt greener construction practices and significantly reduce their carbon footprint.

How is Pidilite integrating smart technologies like IoT and AI into its PPS offerings to enhance waterproofing performance and reduce failure rates?

Pidilite sees digitalisation as a key enabler for improving waterproofing reliability, and we are actively embedding smart technologies across our PPS operations. IoT-enabled tools support remote diagnostics and real-time site audits, allowing us to track application quality and generate predictive maintenance insights. Using AI-led data analysis, we can even anticipate potential failure zones by studying material behaviour, historical performance and environmental conditions. This makes preventive intervention possible, reducing the likelihood of failures significantly. On the diagnostics front, we use advanced tools such as thermal imaging with infrared sensors to detect hidden moisture pockets. Our advanced diagnostics lab is also equipped with LiDAR-based systems and tomography equipment, which help us map the movement of water – even through thick structural elements – and accurately identify the source of seepage. Additionally, several smart instruments are deployed on-site to verify correct substrate preparation, check surface moisture levels, and assess adhesion development of coatings. These technologies collectively ensure that every layer is applied as per specification. By combining smart monitoring with high-performance materials, we are able to deliver far more reliable waterproofing systems while building greater accountability across all stakeholders.

Despite strong domestic growth, a portion of high-performance construction chemicals and raw materials are still imported. What steps is Pidilite taking to reduce import dependency and strengthen local value chains?

Pidilite has always believed in strengthening India’s local manufacturing ecosystem, and this aligns closely with national priorities such as Make in India and Viksit Bharat. Over the past several years, we have invested heavily in developing indigenous technologies and building strong backward integration capabilities. As a result, many of our high-performance construction chemical systems are now fully developed and manufactured in India, customised to suit Indian climatic conditions and on-site construction realities rather than being adapted from global templates. We are also working very closely with domestic raw material suppliers, who themselves are rapidly expanding their capabilities. This collaboration is helping create a more robust supply ecosystem, which is essential for reducing import dependency. In parallel, we engage with Indian research institutes to co-develop formulations that are locally relevant and technically advanced. Our R&D centres are actively developing sustainable substitutes for imported polymers, additives, and other speciality raw materials. These efforts not only support self-reliance but also help us maintain strong cost competitiveness while ensuring high product performance. Overall, through indigenous innovation, local partnerships, and focused R&D, Pidilite is playing a meaningful role in strengthening India’s construction chemicals value chain and reducing dependence on imported materials.

Looking ahead, how do you envision PPS shaping India’s construction landscape over the next five years?

Over the next five years, our vision for PPS is to set a new industry benchmark for durability, sustainability and accountability in the Indian construction ecosystem. We want leak-free, heat-free and energy-efficient structures to become the norm across the country – not the exception. A major part of this journey involves deepening our engagement with architects, consultants and developers. We aim to drive a shift in mindset where durability is integrated into the design stage itself, rather than treating waterproofing or insulation as an afterthought. By embedding these considerations early in the planning process, buildings can achieve far superior long-term performance. We see PPS expanding its technical footprint across both urban centres and emerging markets, enabling projects of all scales – from small residential structures to large industrial facilities – to be built for longevity, resilience and energy efficiency. Our long-term vision is clear: to help build a leak-free, resilient and sustainable India, and to enable the construction fraternity to adopt practices that ensure structures stand strong for decades.

Tags