Interview: Josh Taylor, Vice President – Structural Engineering, Bentley Systems

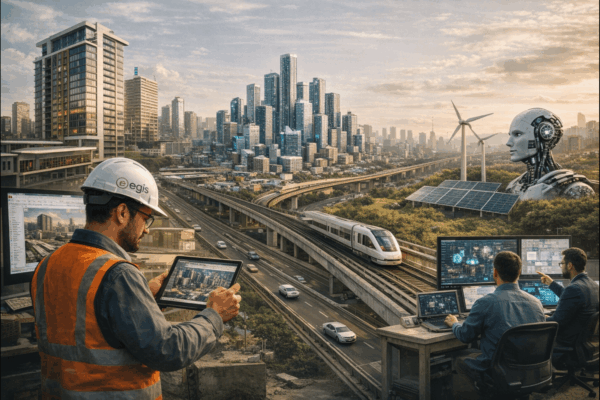

At Illuminate 2025 in Mumbai, hosted by Bentley Systems, Josh Taylor, Vice President – Structural Engineering, spoke with Tejasvi Sharma, Editor-in-Chief of EPC World, on the evolving role of structural engineering in India’s $30 trillion Viksit Bharat 2047 vision. Taylor shared global insights on how the discipline is driving resilience, sustainability, and digital transformation across India’s next-generation infrastructure landscape

India is on a path to becoming a USD 30 trillion economy under the Viksit Bharat 2047 roadmap. From your global vantage point, what are the key structural engineering priorities in India today? How are these shaped by the country’s unique infrastructural and developmental needs?

There’s a lot to unpack here. From the structural engineering standpoint, the Viksit Bharat 2047 vision intersects deeply with sustainability—minimizing reliance on oil and gas, enabling renewable energy, and optimizing the efficiency of what we build. Structural engineers play a foundational role wherever a built environment requires a skeleton, and their work is now increasingly about designing efficiently and using fewer materials. Another priority is developing standards for infrastructure that hasn’t existed long enough to have best practices—like solar panel framing and new forms of energy infrastructure. Some structural assets in India still don’t have comprehensive codes, especially in newer materials or emerging sectors. Regarding seismic resilience, there’s definitely a need to update and expand structural standards. Concrete has traditionally dominated construction in India, and while steel-framed structures are gaining attention, the codes for them are still catching up. For instance, new seismic standards for steel structures only came in 2023. There’s also a desire among Indian engineers for more frequent updates to design codes—similar to the 3–4-year cycle followed in the U.S.—instead of the longer gaps that currently exist.

With India’s infrastructure evolving—metros, expressways, smart cities, high-speed rail—what role does structural engineering play in addressing these complex civil challenges?One of the biggest challenges is working within extremely dense environments, often with poor soil conditions. Structural engineers must overcome significant constraints, especially in cities. That’s where optimized material use, efficient load transfer, and sustainability become vital. A great example is the Coronation Pillar Water Treatment Plant in Delhi. Structural engineers at L&T Construction achieved tremendous space efficiency by optimizing the structural design of tanks and treatment systems, ultimately reducing the land footprint of the plant. Sophisticated analysis and lean design techniques made that possible—this kind of innovation is where structural engineers make their most visible impact.

Especially in seismic regions like the Himalayan base, which do you believe performs better—concrete or steel frame structures?It’s less about the material and more about how well it’s designed and detailed. I’ve worked with both, and both can perform well if proportioned and reinforced correctly. Back in 2001, during my time designing buildings in Seattle, I witnessed how structures reacted to a 6.8 magnitude earthquake. Interestingly, while concrete performed well, it was certain steel connection details—like braced frames—that revealed unexpected behavior. So again, it’s not about choosing one material over another but ensuring that the system is engineered thoughtfully and in line with seismic best practices.

How are expectations evolving from stakeholders—government bodies, private developers, and the public—towards structural engineers today?

The biggest shift is the demand for speed. Project turnaround times are getting tighter, and if an engineering firm can’t deliver quickly, stakeholders simply move to the next option. So, efficiency has become paramount. Yet, amidst this pressure, the core fundamentals of structural mechanics can’t be compromised. No software, no AI, no automation can replace a solid grasp of engineering principles. At Bentley, we often remind our users that the best engineers use technology as an enabler—not a substitute. There’s also a growing need for structural engineers to communicate better—especially with non-technical audiences. Our work is invisible until it fails. But today, when we’re contributing to carbon reduction and sustainability, that story needs to be told more clearly and confidently.

Bentley Systems has been a leader in digital infrastructure. How is Bentley’s structural software portfolio evolving to address today’s demands for speed, scalability, and sustainability?

We’re making significant advances, particularly in our flagship brand STAAD. The software is becoming smarter—with enhanced auto-design capabilities, better optimization tools, and more efficient memory and processing functions. We’re introducing features that assist engineers in quickly identifying performance patterns within designs. In India especially, where speed, cost, and compliance must coexist, we’re ensuring that our tools empower engineers to balance all three. A major release is STAAD Foundation Advanced 2025, which will offer full compliance with both Indian and U.S. standards for all major foundation types. That’s a big leap from earlier versions. We’re also integrating ADINA, our advanced analysis software, into the Structural WorkSuite license. This gives Indian engineers access to sophisticated simulation capabilities for complex structural behavior—all in a cost-effective manner.

Are there any AI-powered features being introduced? What can users expect next?

Yes. One of the first AI-integrated features will be the STAAD Documentation Co-Pilot powered by GPT. It allows engineers to navigate STAAD’s vast technical documentation more intuitively, accelerating learning and troubleshooting. Later this year, we’re aiming to add intelligent design assistance tools that go beyond documentation—features that help users reach optimal design paths faster through smart suggestions, reducing trial-and-error cycles. This is the direction we’re headed in with AI.

With global pressure to achieve net-zero and ESG benchmarks, how does Bentley help structural engineers contribute to sustainable infrastructure?

Our iTwin platform includes a carbon calculator that integrates with our structural analysis tools like STAAD, RAM, and SACS. This allows engineers to assess embodied carbon during the design phase itself. Besides that, our optimization capabilities inherently promote leaner designs—reducing material consumption, which is a huge contributor to sustainability. We’re essentially helping engineers achieve more with less.

Finally, if you had one message for young structural engineers in India—especially those just entering the workforce—what would it be? What future do you envision for structural engineering as a discipline?

I must say, I’m genuinely impressed by the level of engineering sophistication in India—particularly in the infrastructure domain. The submissions we receive for our Going Digital Awards clearly reflect how Indian engineers are not just adopting digital tools but are using them strategically to optimize structural systems. It’s both inspiring and commendable. To young engineers: remain deeply rooted in the fundamentals. Embrace technology, but never lose sight of core engineering principles. And importantly—communicate your contributions. Structural engineers play a critical role in shaping resilient and sustainable infrastructure; it’s time the broader world understands that value.

Looking ahead, the future of structural engineering will be defined by resilience, sustainability, and intelligent design. In a country like India—where seismic activity, poor soil conditions, and intensifying climate events such as cyclones are growing concerns—structural engineers are vital. Designing for performance, safety, and environmental responsibility is no longer optional—it’s essential. On that note, testing and model simulation facilities play a crucial role. As we move toward new materials and more advanced seismic-resistant design, India must invest in strengthening its physical testing and simulation infrastructure. Digital twins and sophisticated simulations are powerful tools, but they must be grounded in real-world validation. A robust ecosystem of testing labs is indispensable for ensuring the safety, reliability, and future-readiness of our built environment.

Tags