Interview: Harsh Pareek, Vice President – Direct Sales, Asia-Pacific, Trimble

Trimble’s tools support sustainable construction in India’s urban housing sector by making every step of the building process more efficient and resource-conscious

How do Trimble’s model-based workflows ensure that prefabricated components designed for affordable housing projects in India are manufactured and assembled with exact precision on-site?

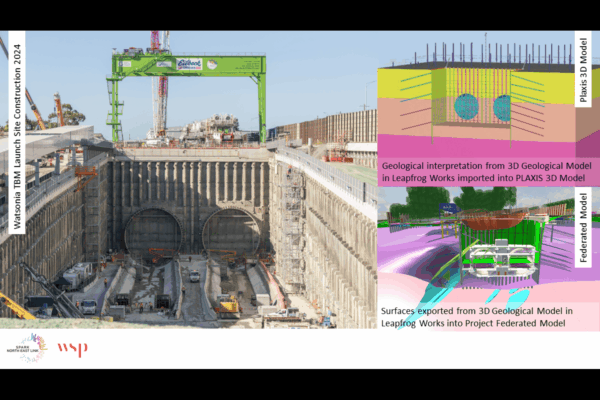

India is experiencing a rising demand for affordable housing and the challenge is not just to build more houses but also to do it with precision, longevity and quality that lasts. In order to achieve this, Trimble’s model-based workflows redefine the design, production and on-site assembly of prefabricated homes, guaranteeing that every part fits together correctly. Every aspect of a project is planned in a comprehensive 3D environment using Building Information Modeling (BIM), from the positioning of plumbing and electrical systems to the arrangement of wall panels. The production of components with precise measurements and stringent quality checks is based on this digital blueprint. The same model directs the assembly process once these components arrive at the location, guaranteeing that every component fits together perfectly. This excellent degree of coordination speeds up building, lowers error and contributes to the delivery of well-made, reasonably priced homes throughout India.

In what ways do Trimble’s connected BIM tools specifically help minimise rework and material waste in cost-sensitive urban housing projects?

In cost-sensitive housing projects, even minor mistakes can cause major delays and increase costs. This is resolved by Trimble’s integrated BIM tools, which offer a unified, coordinated digital model that functions as the project’s final point of reference. Errors during construction are significantly reduced because every panel, utility line and structural element is planned, examined and approved within this model before production starts. These tools ensure that problems between building systems are resolved virtually rather than on-site via early clash detection and design validation during planning. For the production of prefabricated parts, which are made with precise dimensions, the digital model offers precise specifications. Teams on-site then assemble the parts according to the model, making sure every part fits precisely, avoiding mistakes and misalignments.

How do Trimble’s BIM solutions enable developers and contractors to adhere to the stringent timelines often required in India’s affordable housing sector?

Delivering affordable housing in India requires construction projects to stay on very tight schedules. This is made possible by Trimble’s BIM solutions, which provide developers and contractors with a comprehensive digital model of the project. This reduces errors and delays by helping teams to precisely plan each step and foresee problems before they occur. BIM also combines the process of design, prefabrication and assembly. While site preparation is ongoing, components can be manufactured offsite, allowing for parallel workflows that shorten the construction timeline overall. This ensures that every component fits correctly the first time by providing step-by-step installation guidance on-site. Further, the centralised platform improves collaboration among architects, engineers and construction teams, keeping everyone aligned and informed.

How are Trimble’s prefab-ready solutions addressing the scalability challenges of affordable housing in rapidly expanding Indian cities?

Scaling affordable housing isn’t just about speed; it’s about being able to repeat success across many projects without losing quality. Trimble’s prefab-ready solutions make this possible by connecting design, detailing, and factory production in one workflow, so every panel or beam comes out right the first time. Because designs can be adapted and replicated directly from the model, contractors save time, avoid errors and cut waste, making it easier to deliver housing quickly and at scale in India’s rapidly growing cities.

In what ways do Trimble’s tools contribute to sustainable construction practices in the context of urban housing development in India?

Trimble’s tools support sustainable construction in India’s urban housing sector by making every step of the building process more efficient and resource-conscious. By carefully planning projects before construction starts, BIM helps prevent wasteful material use and mistakes made on the job site. During construction, this meticulous planning lowers waste and energy use. Using modular and prefabricated components improves sustainability even further. Construction teams can reduce the amount of time spent on-site and reduce environmental disturbance by preparing the site concurrently through manufacturing building components off-site. This approach guarantees more effective handling of materials, reducing waste and rework.

How does Trimble Connect’s real-time issue tracking sync with Indian EPC firms’ ERP systems to reduce rework by 25-30% in mid-rise housing projects?

Trimble Connect offers a centralised platform for real-time collaboration and communication among team members, which improves problem identification in mid-rise housing projects. This integration reduces rework and delays by enabling quick issue identification and resolution. Trimble Connect further provides effortless data sharing between office and construction site teams through its integration with ERP systems. This ensures that everyone has access to the most recent data, helping project managers to allocate resources effectively and make quick and accurate decisions. The system increases project efficiency by reducing rework and preventing errors by providing real-time updates to all teams.

Tags