We Build the Greenest Vessel for the Greenest Energy

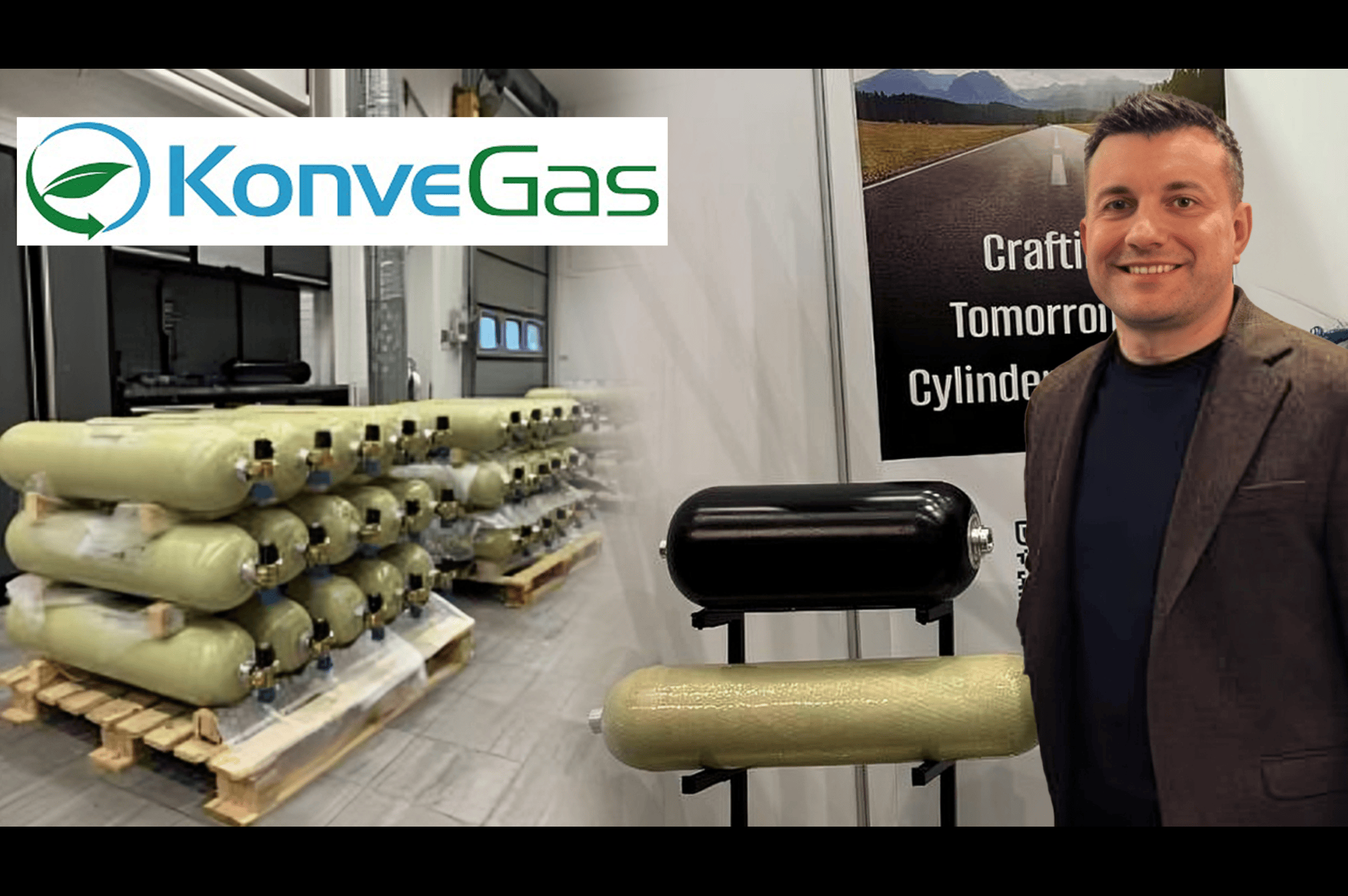

As the energy transition accelerates, KonveGas Sweden AB is leading the way with its innovative composite cylinders—lightweight, durable, and low-carbon solutions for hydrogen, biogas, and CNG. In an exclusive interaction with EPC World, ALEXANDER ENULESCU, CEO, shares how the company is scaling production, reducing lifecycle emissions, and partnering with EPCs and OEMs to drive the future of clean energy infrastructure in Europe, India, and beyond.

Mr. Enulescu, how is KonveGas leveraging composite cylinder technology to support the global clean energy transition, and what is your strategy to scale production and supply chains to meet growing demand across mobility, LPG, hydrogen, and industrial gas markets, particularly for EPC-led projects in Europe and India?

At KonveGas, we see ourselves as delivering the ‘greenest vessel for the greenest energy.’ The energy transition cannot succeed if emissions are merely shifted from the tailpipe to the supply chain. That is why our composite cylinder technology is built around a low-carbon raw-material strategy and locally anchored supply chains, ensuring that the distribution of hydrogen, biogas, and CNG remains as clean as the fuels themselves.

Our approach to scale is based on resilience and localisation rather than volume alone. We use a modular manufacturing model with standardised Type-4 production cells that can be replicated globally while maintaining strict quality and safety control. In key markets such as India, we are advancing a local-assembly strategy that combines Swedish engineering and validated processes with regional production partnerships. This reduces lead times, logistics emissions, and overall cost without compromising performance.

In terms of demand, clean mobility and the CNG transition are driving the strongest near-term growth, particularly where biomethane and existing infrastructure enable rapid emissions reduction at scale. Hydrogen storage represents the next major growth phase, though it remains more project-driven, while industrial gases serve selective applications where weight, handling, and safety are critical.

To support high-volume EPC and infrastructure projects in Europe, India, and beyond, we are building a supply-chain model that is regional, scalable, and secure. By relying on raw materials that are naturally abundant and locally available, we reduce dependency on long transport routes and lower embedded emissions—making our composite cylinders eco-friendly by design.

How does KonveGas minimise lifecycle carbon footprint through low-energy manufacturing and circular design, and how is growing customer demand for measurable sustainability influencing your strategy?

At KonveGas, ‘low-carbon by design’ begins with our raw-material philosophy. We prioritise composite systems based on naturally abundant, non-fossil resources that can be produced locally, reducing dependence on long transport routes and lowering embedded emissions. A clear example is our use of glass fibre, which offers a significantly lower carbon footprint and stronger regional supply resilience compared to carbon fibre.

Our manufacturing model is highly industrialised, with stable, repeatable process control that minimises scrap, rework, and energy intensity. Lightweight cylinder design further reduces emissions during transport, handling, and operation over many years of service. We also focus on extended, certified service life and responsible end-of-life pathways aligned with local regulations, reducing the footprint per year of operation.

This lifecycle-driven approach aligns closely with EU decarbonisation frameworks such as ‘Fit for 55’ and responds to growing global demand for measurable sustainability in procurement. While Europe already mandates lifecycle CO₂ transparency, markets like India are rapidly moving in the same direction as clean mobility and alternative fuels scale up. KonveGas’ Type IV cylinders are designed to meet both mature and emerging sustainability expectations—delivering low lifecycle emissions without compromising safety or performance.

How do KonveGas’s engineering standards and global certifications ensure durability and safety, and what have real-world deployments revealed about the operational benefits of lightweight, corrosion-free composite cylinders?

KonveGas Type IV cylinders achieve high impact resistance and durability through the inherent behaviour of glass-fibre composite materials. The composite architecture offers high strain tolerance, effective energy absorption, and damage containment, enabling the cylinders to withstand impact, vibration, and harsh field conditions. All products have successfully passed mandatory impact, fatigue, and environmental qualification tests and are already deployed in real vehicle applications, confirming robust performance under operational conditions.

Our design and testing are governed by internationally recognised standards, including ECE R110 for automotive applications, ISO 11119-3 for composite gas cylinders, and EN 12245 for transportable composite pressure vessels. These frameworks require extensive validation—covering burst pressure, cyclic fatigue, impact resistance, fire exposure, and environmental durability such as temperature cycling, humidity, chemical exposure, and vibration—ensuring consistent safety margins across diverse and demanding environments, including markets such as India.

From an operational perspective, the lightweight and corrosion-free construction of our composite cylinders supports improved efficiency, payload utilisation, and long-term reliability, depending on the application and duty cycle. Field deployments across passenger and heavy-duty vehicles, including off-road use, have accumulated hundreds of thousands of kilometres of operation. Performance has been further validated through close collaboration with customers during application-specific evaluations, with no durability or safety limitations identified and all certification requirements met with approved results.

How is the shift from steel to advanced composites reshaping energy storage infrastructure, and how is KonveGas aligning R&D, hydrogen readiness, and collaboration with EPCs and OEMs to support next-generation clean fuels?

Material choice is increasingly critical for the future of energy storage infrastructure, balancing durability, safety, performance, and lifecycle CO₂ impact. KonveGas’ strategy centres on high-performance glass fibre composites paired with optimised resin systems, delivering superior strength, fatigue resistance, and long-term reliability while reducing carbon footprint. Our cylinders are designed for both mobility and stationary hydrogen storage—including cascade and modular systems—with advanced composite architectures that ensure safe operation under dynamic and static conditions. Collaboration with EPCs, OEMs, and utilities further informs product design and system integration, ensuring real-world applicability while adhering to rigorous international safety and performance standards.

How do KonveGas cylinders achieve a 20-year certified service life, reduce maintenance compared to metal vessels, and deliver long-term economic benefits beyond the upfront cost?

KonveGas Type IV cylinders are certified for a 20-year service life through conservative design, robust structural layouts, and comprehensive international-standard testing, including extended pressure cycling to validate durability and fatigue resistance. Their composite construction ensures long-term structural stability while reducing maintenance compared to metal vessels, provided inspections follow regulatory and manufacturer guidelines. From a strategic perspective, buyers should consider total cost of ownership, factoring in service life, operational efficiency, reliability, and risk mitigation, as well as lifecycle carbon footprint. This lifecycle-driven approach delivers predictable performance, supports regulatory compliance, and enhances long-term economic and environmental value for mission-critical energy infrastructure applications.

What should EPC companies and engineers know about integrating composite cylinders into large projects, redesigning storage and distribution systems to leverage their advantages, and how should standards evolve to accelerate adoption?

EPC contractors should approach composite cylinders as an integral part of system design, addressing interfaces, installation conditions, and regulatory requirements early to ensure efficient, compliant, and predictable project delivery. Engineers can maximise the advantages of composites by redesigning storage and distribution systems at a holistic level—optimising layout, weight distribution, and modularity rather than simply replacing components. Widespread adoption can be further supported by performance-based, technology-neutral standards and closer alignment between global and regional codes, with ongoing collaboration between regulators and industry to keep standards in step with real-world deployment while maintaining safety.

Why is India a strategic market for KonveGas, how do you see composite storage technology evolving over the next decade, and what message would you give to engineers and policymakers driving the clean energy transition?

India represents a high-growth, strategic market for KonveGas, driven by significant investments in renewable energy, alternative fuels, and sustainable infrastructure. The country’s pragmatic, forward-looking policy environment aligns with our vision of energy systems that combine performance, sustainability, and local value creation. Over the next 10–15 years, we expect composite storage technology to play a central role in enabling decentralised, low-carbon energy systems, with advances in materials, manufacturing, and standards supporting broader adoption across mobility and stationary storage. My message to engineers and policymakers is to adopt a long-term perspective—decisions on materials, performance, environmental impact, and recyclability made today will shape the resilience and sustainability of energy systems for decades to come.

Tags