Integrating CHP, hybrid and energy storage for greener and reliable energy

by Sarang Modi, Head – Sales and Marketing, CoGen, Sterling and Wilson

Thermal power stations have always played a central role in the energy sector. Even today, they are fulfilling up to 85% of the world’s electrical power demand. By their very nature – of being heavily dependent on fossil fuels, they happen to be responsible for causing significant air pollution and occasioning heat loss during energy distribution.

On-site power generation, also known as distributed generation or decentralized energy, refers to the electric power produced at the site of consumption, which reduces dependence and peak demand on the grid.

Through cogeneration or combined heat and power (CHP), on-site power generation addresses many of the challenges faced by traditional thermal power plants. CHP systems are usually located nearby or within the precincts of business establishments, offices, and residential places.

It is interesting to note that Pearl Street Station, the world's first commercial power plant built by Thomas Edison in New York City in 1882, was based on the CHP concept. The plant routed waste heat to generate steam that helped heat nearby buildings and manufacturing facilities. Now, once again, CHP systems are becoming increasingly important in the energy sector’s transformation to a more decentralized, stable, and sustainable future.

CHP: Putting power in the hands of end-users

In traditional coal and gas-fired power stations, up to 67% of the energy used in the generation process is discharged into the atmosphere, resulting in thermal energy loss. Additionally, around 7% of heat is lost during the distribution of electricity to end-users. On the other hand, CHP is an energy-efficient technology that concurrently generates electricity or mechanical power, and heat from a single source of energy. The source can be a fossil fuel, such as fuel oil or natural gas, or a renewable fuel such as biogas or biomass.

The thermal energy so generated in the CHP process can be utilized in industrial processes or for space heating, supplying domestic hot water, or cooling. This way, the heat that would otherwise be lost by traditional thermal power generation is captured, and efficiencies of over 80%, can be achieved, as compared to 50% for typical technologies involving conventional electricity generation and an on-site boiler.

With its ability to generate 24×7 power, the CHP model is highly reliable, besides also being cost-effective. It allows for faster deployment, with fewer geographic limitations. As CHP plants also make better use of the fuel utilized by them, saving anywhere between 15%–40% of the energy in total, they contribute towards fuel supply security. Operators typically save fuel costs and energy bills. CHP can reduce carbon emissions by up to 30% compared to the separate means of conventional energy generation via a boiler and power station.

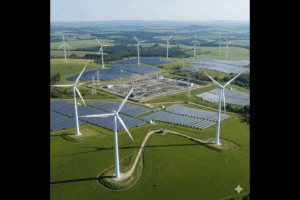

While CHP goes a long way in achieving decentralization and stability in power generation, it doesn’t completely eschew reliance on coal. However, when the on-site power generation system is configured as a hybrid system, integrating CHP with either solar or wind, it helps bring down the carbon footprint of the overall energy generation system, further. For example, under favourable daytime conditions, the solar photovoltaic (PV) system could generate enough power from 8 am to 6 pm, after which the CHP system can take over.

Energy storage with EMS: The future of reliable, uninterrupted power

Renewable energy sources such as solar PV and wind energy, much as they are clean, have an intermittent output, which can be variable, uncertain, and unreliable, depending upon weather conditions.

Energy storage, when introduced in a hybrid on-site power generation system incorporating CHP and solar, makes a winning configuration and opens the doors to a whole new world of hybrid – making the process not only efficient and cost-effective but the power also clean reliable, and stable. Furthermore, this configuration reduces dependence on the grid and fossil fuels, and provides power 24×7, while providing resiliency and seamless transition.

Most storage technologies are capable of discharging power to the grid quickly – in a matter of milliseconds, unlike traditional fossil fuel sources, which tend to take longer to ramp up. Such a rapid response is crucial for ensuring the stability of the power generation system – especially when demand surges. Islands and microgrids that are disconnected from the larger electrical grid system benefit the most from energy storage, in turn ensuring power stability.

In any organization, energy management plays an elemental role in monitoring, conserving, and controlling energy. Using an Energy Management Software (EMS), a user can effectively monitor, control, and optimize the performance of the power generation system. The EMS plays the most important role in hybrid power generation project deployments, managing assets and keeping voltage, frequency, and KVAR consistent. It helps identify the most cost-effective configuration of producing power, transmitting, and distributing it within a network, while emphasizing the required criteria for system stability, safety, and reliability.

EMS solutions measure energy consumption and collect data before identifying energy-saving opportunities and estimating the quantum of energy that can be saved, allowing any critical facility to rely on on-site hybrid power generation. Several hybrid projects in Africa and remote islands serve as a testimony to its adoption globally.

Energy storage, along with EMS, is the game-changer that is allowing operators to become completely self-reliant and free from the traditional grid. There is a growing consensus that hybrid, on-site power generation systems incorporating CHP with solar and energy storage are the way forward for large-scale electricity and heating supplies, and in time we will likely see a growing number of these configurations across the world.

TWA hotel: A model Cogen plant with energy storage

The 512-room TWA Hotel at New York’s John F Kennedy airport, with its industrial-grade SCADA and PLC control system, features an advanced CHP microgrid, inclusive of a 1 MW cogeneration plant coupled with a 1 MWh battery storage system, along with reciprocating engines and an energy management system solution. This system is particularly unique in the fact that it is completely disengaged from the local electrical utility during all modes of operation. The battery is used as a ‘grid former’, varying its rate of discharge (or charge) to maintain the voltage and frequency of the hotel and the conference centre’s electrical grid. The plant control system has allowed the hotel, conference centre, and flight centre to rely completely on the cogeneration plant for its energy.

Related Posts