From Craft to Code: How Modern Manufacturing is Transforming Architectural Hardware

by Aditya Bhargava, Product Development & Operations, The House of Jolly

Architectural hardware is often treated as a finishing detail – something chosen toward the end of a project. In reality, it plays a far more fundamental role. Hardware is a system component that directly affects safety, durability, usability, and the long-term performance of a building.

As construction across housing, commercial, institutional, and public spaces grow in scale and complexity, expectations from architectural hardware have changed. What was once driven largely by artisanal skill is now being reshaped by engineering discipline and digitally governed manufacturing.

Craft: The Foundation, Not the Finish Line

Traditional craft laid the foundation of architectural hardware. Skilled workmanship, material intuition, and design sensitivity produced pieces that were expressive and long-lasting. Many historic buildings around the world still rely on hardware made decades or even centuries ago.

However, craft-led production has natural limits. It depends heavily on individual skill, allows variation in output, and does not scale easily. As buildings become larger and usage becomes more intense, tolerance for inconsistency reduces. In such environments, even small deviations can lead to wear, failure, or maintenance challenges over time.

Craft Created Character. Modern Buildings Require Consistency

Engineering Brings Structure

The shift from craft to modern manufacturing did not mean abandoning craftsmanship. It meant structuring it.

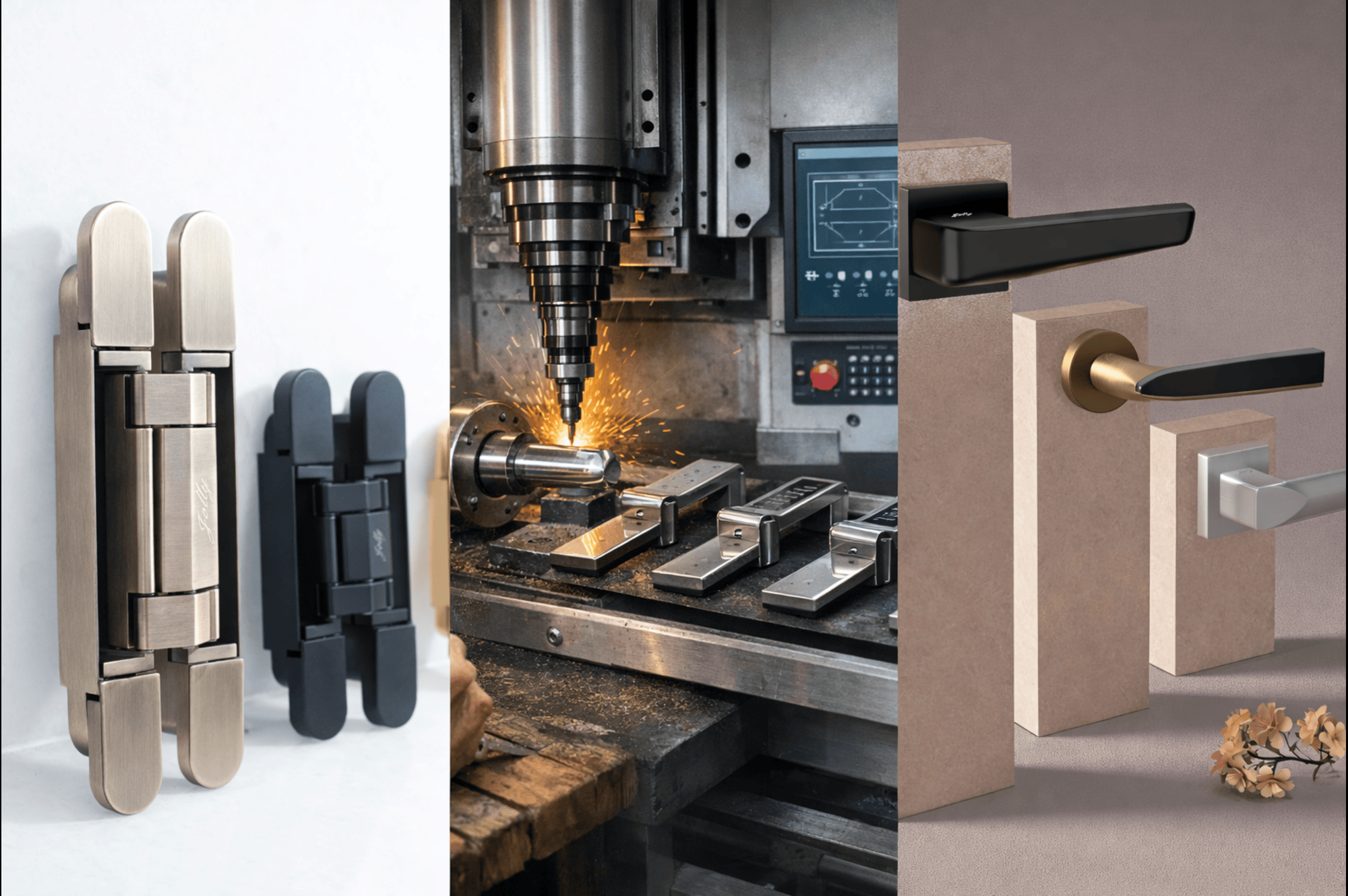

Engineering introduced standardisation, material science, lifecycle testing, and performance benchmarks. Hardware evolved from being primarily decorative to becoming functional, measurable, and dependable. This transition made it possible to deliver the same quality repeatedly—across projects, geographies, and volumes.

Processes such as precision forging, followed by controlled machining, improved structural reliability while reducing internal stress in components. This ensured that products could withstand long-term use without compromising performance.

Code: Manufacturing in the Digital Era

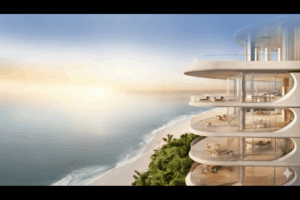

The most significant transformation today is being driven by code—digitally enabled manufacturing systems that govern how products are designed, produced, finished, and tested.

Computer-controlled machining allows for exact tolerances to be maintained consistently. Automated finishing and polishing systems ensure that surface texture, tactile feel, and appearance remain uniform across large production runs—something manual processes struggle to achieve at scale.

Surface engineering has also evolved significantly. Advanced processes such as PVD coating have transformed finishes from decorative layers into performance-driven systems. These coatings improve corrosion resistance, enhance durability, and ensure colour consistency across batches, especially in high-use environments.

Digitised quality control adds another layer of reliability. Inspection data can now be logged, reviewed, and refined across batches, introducing traceability and accountability into the manufacturing process. Quality is no longer assumed; it is measured.

Why This Shift Matters

When architectural hardware is engineered and digitally governed, the impact is tangible. Installation becomes predictable. Performance becomes consistent. Longevity becomes intentional.

In buildings where hardware is used thousands of times every day, reliability cannot be left to chance. Manufacturing processes must ensure that what is approved in design performs the same way in real-world use, across time.

Mechanisation plays a key role here. Unlike automation, which focuses on speed, mechanisation focuses on control. It ensures repeatability, reduces human fatigue-related errors, and maintains consistency across volumes. This control is what allows manufacturers to deliver dependable outcomes at scale.

Design Integrity Still Matters

As manufacturing becomes more technical, design integrity becomes even more important. The goal is not to replace sensitivity with systems, but to ensure that design intent is faithfully translated into performance.

Well-designed hardware should feel intuitive to use. It should sit quietly within a space, doing its job without drawing attention to itself. The balance between engineering precision and human experience is where true manufacturing maturity shows.

The most effective manufacturers understand both—how a product is made, and how it is used.

Looking Ahead

The future of architectural hardware lies in deeper integration with building systems and longer-term thinking around sustainability. Longevity will matter more than novelty. Precision will matter more than excess.

Sustainability, in particular, will be driven by durability. Products that last longer, perform consistently, and reduce the need for replacement will define responsible manufacturing. Advanced coatings, controlled processes, and data-backed quality systems will be central to this shift.

Technology will continue to evolve, but the principle remains unchanged: manufacturing must support people, buildings, and systems over time.

Conclusion

The journey from craft to code is not about replacing human expertise. It is about amplifying it through discipline, structure, and technology.

As architecture evolves, architectural hardware must evolve with it—quietly supporting spaces through reliability, consistency, and thoughtful engineering.

In the end, manufacturing excellence does not announce itself.

It earns trust, over time.

Tags