Enhancing concrete performance: Cutting-edge solutions for durable and high-quality structures

by Rajiv Upadhyay, President APAC and India, Saint Gobain Construction Chemicals

The construction industry is experiencing multi-fold transformation with a strong focus on enhancing the performance of concrete through innovative solutions. Concrete – one of the most used and known for strength, versatility, and durability, serves as the primary construction material globally. However, to ensure the long-term performance of concrete structures, there is a need to enhance their quality and durability further. In recent years, remarkable progress in concrete technology has resulted in the emergence of advanced solutions that elevate concrete performance. These include concrete admixtures, construction systems, and cutting-edge cement grinding techniques, establishing certain companies as frontrunners in this field.

Sustainable concrete will truly revolutionize the construction industry by providing a greener and more eco-friendly alternative to traditional concrete. Its impressive combination of durability, strength, and low carbon footprint makes it a preferred choice for sustainable construction projects. The incorporation of supplementary cementitious materials like fly ash or slag, along with the use of recycled aggregates, significantly reduces the demand for virgin materials and helps minimize waste generation. This shift towards a circular economy in construction is a significant step in the right direction. Furthermore, the implementation of advanced manufacturing techniques and admixtures not only improves the quality of sustainable concrete but also reduces energy consumption during production, making the construction process more sustainable and resource efficient. By opting for sustainable concrete, we can effectively reduce greenhouse gas emissions and enhance the overall environmental performance of buildings and infrastructure. It's an exciting development that is paving the way for a more sustainable future in the construction industry.

Concrete Admixtures: Helping transform concrete properties

Concrete Admixtures play a vital role in enhancing the performance of concrete structures. By adding chemical formulations to concrete, these admixtures modify concrete properties – resulting in improved workability, strength & durability. Overall helping to reduce cracking, enhance curing, and provide protection against adverse environmental conditions.

In recent years, advancements in admixture technology have provided precise control over concrete characteristics and performance. Superplasticizers, also known as high-range water reducers, are gaining popularity for their ability to improve workability without compromising strength and other properties of concrete.

Optimizing efficiency and sustainability in construction practices

The construction industry is undergoing transformation to enhance concrete performance. Precast concrete, reinforced concrete, and post-tensioning techniques are revolutionizing construction by improving efficiency, cost-effectiveness, and sustainability.

Precast concrete systems involve manufacturing components off-site and then assembling them on-site, resulting in greater precision, faster construction timelines, and reduced waste. Concrete reinforced with steel bars, enhance load-bearing capacity for large-scale projects. Post-tensioning techniques helps to strengthen the concrete, enabling the construction of longer spans and thinner slabs.

As a collective force, these advanced technologies are revolutionizing the industry by maximizing efficiency, optimizing costs, and promoting sustainability. Through their integration, the construction sector is embracing a future characterized by enhanced performance, environmental consciousness, and a commitment to progress.

In the pursuit of optimizing efficiency and sustainability in the construction industry, concrete admixtures emerge as powerful allies. These chemical additives not only enhance the performance of concrete but also support sustainable construction practices. Admixtures such as water reducers enable the reduction of water content in concrete, improving workability while minimizing water usage. This reduces the energy required for mixing and decreases the carbon footprint associated with concrete production. Additionally, supplementary cementitious materials like fly ash and slag replace a portion of cement, reducing greenhouse gas emissions and conserving natural resources. By incorporating concrete admixtures, the construction industry can achieve higher efficiency, lower environmental impact, and contribute to the development of more sustainable built environments.

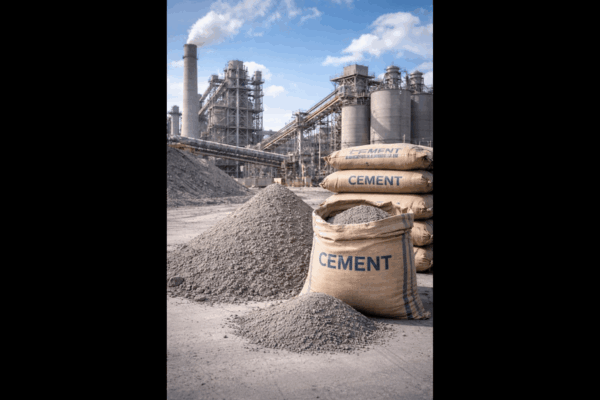

Cement grinding: Helping reduce carbon footprint

Being one of the largest cement producer, cement manufacturing contributes to very high CO2 emission. Where cement grinding aid helps cement producer to cut down CO2 emission, performance enhancers enable them to use industry waste such as fly ash, blast furnace slag, etc. Cement grinding aid not only support the environmental aspects but also enhance the quality of cement produced while increasing strength at all edges.

Elevating concrete performance towards a sustainable future

We are building more bridges, taller buildings & complex transport systems to cater the surge of increasing urban population. While building we have to balance between high strength, challenges in concrete placement & sustainability. Construction chemical industry is evolving every day to meet these challenges while keeping their eyes on sustainability. New technology for higher strength, better placability, enabling contractors to produce slender structures which are designed for long life span while keeping the carbon footprint in limits. Besides this the concrete producers & contractors are adapting to new methods which enables them to make better homes & infrastructures. They are continuously harping on reduced energy consumption, faster pace of construction & EHS of their employees.

Within the quest for advancing concrete performance, prominent industry leaders have emerged, and among them, Saint-Gobain Chryso stands out for its significant contributions to the construction sector. By embracing innovative solutions and fostering collaborations with forward-thinking companies, the construction industry can ensure the delivery of high-quality structures that exhibit longevity. This collective effort lays the foundation for a future where structures are not only functional and durable but also imbued with sustainability and environmental consciousness. At the forefront of this movement, Chryso by Saint-Gobain provides comprehensive additive solutions for sustainable construction. Their cutting-edge additives assist in significantly reducing concrete's carbon footprint, addressing the environmental impact associated with traditional construction practices.