Data: The Fuel for India’s Next-Gen Rail

As India advances toward its net-zero goals, the rail sector is emerging as a key enabler of sustainable transport. With over 95% of the network electrified, the focus is now on optimizing operations for safety, efficiency, and long-term performance. In this article, Vyankatesh Patole, Solution Consultant at Hexagon Asset Lifecycle Intelligence, highlights how data, digitalization, and advanced asset management are transforming rail infrastructure—enabling predictive maintenance, smarter investment planning, and a more connected, future-ready ecosystem.

Can rail live up to expectations? Across the world, several regions and governments have unveiled large-scale plans to develop rail, the least emission-intensive mode of transport.

India recently announced that it had electrified 95% of its rail network to advance its net zero 2030 objectives.

To achieve these objectives, there are several factors in play. Rail system operators face the difficult balancing act of ensuring safety and state of good repair of their existing networks.

Data- and AI-driven railroad maintenance

Building and operating these railways goes far beyond laying kilometers of tracks. Despite their old-fashioned image, rail networks create vast amounts of data through control systems and sensors. However, the value does not always lie with creating more data, but in collating and analyzing granular data, turning it into actionable insights and automating actions based on these insights.

One of the areas where results have been the most striking is predictive maintenance. Using HxGN EAM, a leading asset management platform, major rail operators have been able to leverage data and machine learning algorithms to predict asset failure and support real-time decision-making – an approach that has been proven to reduce equipment downtime by 30-50% and increases its lifetime by 20-40%.

The platform also takes into account resource availability to optimize maintenance schedules and save time by digitizing processes and making them mobile – two crucial dimensions in a context of strained resources and skills shortages. One of the key results is an increase in planned maintenance that reduces emergency maintenance and road calls.

Better investment planning

The use of data does not stop there: recent approaches, such as Asset Investment Planning (AIP), help operators get a glimpse of the future and the impact of potential investments.

Using asset data, it helps rail companies project how to best deploy their limited financial resources to manage their network and asset base and meet their service level objectives. This strategy requires bridging the gap between different dimensions, such as asset lifecycle monitoring, long-term capital planning and service level agreements.

AIP builds on another approach, Asset Performance Management, or APM. Modern APM combines traditional asset management practices with new digital technologies for transformation advances in reliability, centered maintenance execution, asset health and asset condition. It helps companies align their maintenance practices align with business priorities and objectives.

Both approaches are crucial in rail, a sector where asset maintenance can consume up to 20% of a company’s total revenue. Many investment decisions, such as decisions to repair or replace an existing asset, upgrade equipment or expand services can come with costly consequences if they fail to leverage data and are shaped by faulty assumptions.

Visibility across the trains’ complete lifecycle: the case of Stadler

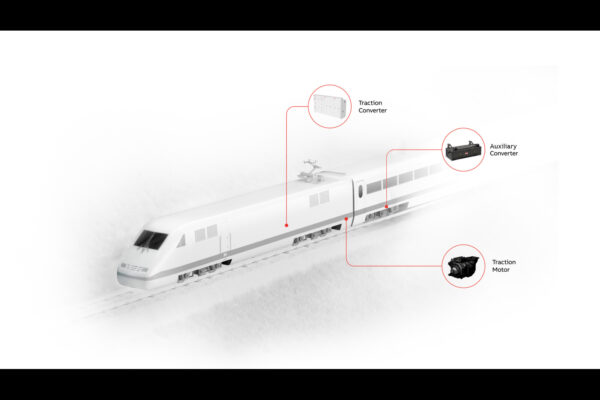

Train operators are undergoing the same journey towards greater use of data to optimize maintenance and operations.

Take the example of Stadler Rail Group: headquartered in Switzerland, the company was initially specialized in train manufacturing, a category in which it had become the global leader in the rack-and-pinion vehicle market and a developer of high-speed trains such as the SMILE, which can reach speeds up to 250 km/h. Increasing privatization worldwide – particularly in the regional rail sector – offered the company the opportunity to expand its focus to the maintenance of rail vehicles.

This new activity comes with its own set of challenges, such as stringent and evolving compliance requirements that vary across geographies and the importance of warranty management.

Today, all maintenance activities at Stadler Rail are recorded and tracked in HxGN EAM, providing Stadler with the capability to map a new train fleet, including definition of maintenance activities, in a single system. For Stadler, a company that associates manufacturing and maintenance, a particularly promising perspective is having visibility across a train’s and a fleet’s complete lifecycle – from the assembly line to the maintenance workshops.

Digitization and automation

Achieving such visibility across the complete lifecycle of tracks or rolling stock is a complex endeavor.

For one, many rail companies struggle with multiple, scattered solutions that are not integrated, with each covering a small part of their activity. Key operational processes, such as inspections or shift handover, may also be largely manual and rely on outdated tools. In addition, companies often rely on a number of third-parties, making interoperability even more difficult. However, solutions exist to overcome these hurdles.

A crucial first step is the digitization of field procedures, with mobility and ease-of-use as pre requisites. Well conducted, this digitization can bring a number of material benefits: immediate visibility over operations, greater safety by reducing human errors and miscommunications and significant time savings by eliminating tedious clerical tasks, to name a few. A solution such as j5 can rapidly deliver full coverage of field operations.

At the scale of a vast rail networks or a large fleet, automation has an important role to play. It can enrich the data collected, for example with geolocalization or asset information, and support and automate better decision-making. Change detection technologies, for example, can support autonomous train operations or railway track inspections.

Digital twin

What is the end-game of these digitization efforts? Combining and visualizing all asset, spatial and other data that was previously spread across multiple systems, departments and formats into a dynamic digital twin that serves as a single pane of glass.

Implementing a cutting edge digital twin solution, such as HxGN SDx, can fulfil a large range of uses and revolutionize daily operations. For a maintenance technician, it can drastically increase productivity by providing all necessary information in one place, optimizing schedules, and pinpointing the exact intervention that is needed. Management can gain a comprehensive view of operations and identify where investments are needed, what outcomes would result from different scenarios.

Over time, these benefits compound. Companies that can rely on high-quality tools and a data driven culture enjoy a competitive advantage in safety, efficiency and, ultimately, profitability. And, at a time when the rail sector is undergoing a large transformation and increased competition, the stakes could not be higher.

Tags