Capex Boost and Policy Tailwinds to Fuel Cement Sector Growth

Union Budget 2026–27 has set the ball rolling for the cement sector. By combining robust capital expenditure with policy measures aimed at infrastructure-led growth, and with public capex raised to ₹12.2 lakh crore alongside renewed focus on Tier II and III cities, the Budget is expected to support steady cement demand across housing, industrial, and transport project

The Indian cement industry has much to cheer as macroeconomic stability and a renewed policy push on infrastructure set the stage for sustained demand growth. The Reserve Bank of India’s decision to keep the repo rate unchanged has provided comfort on financing costs, while the Union Budget’s strong emphasis on capital expenditure has reinforced confidence across construction-linked sectors. “The increase in public capex to ₹12.2 lakh crore, the focus on Tier 2 and Tier 3 cities, and the creation of City Economic Regions stand to strengthen the growth of the Cement sector. We welcome the Budget’s emphasis on tourism, cultural and social infrastructure, which should broaden construction activity across regions. Investments in tourism facilities, heritage and Buddhist circuits, regional connectivity in Purvodaya and North Eastern States, and the strengthening of emergency and trauma care infrastructure in district hospitals reinforce the Cement sector’s role in enabling inclusive growth,” said Dr Raghavpat Singhania, Vice President, Cement Manufacturers’ Association. As India aspires to become the world’s third-largest economy, infrastructure development remains the single most critical lever – and cement sits at the very heart of this transformation.

Key Budget and Policy Tailwinds for the Cement Sector

The Union Budget 2026–27’s capital expenditure set at ₹12.2 lakh crore forms the cornerstone of the government’s infrastructure-led growth strategy and provides strong multi-year visibility for cement demand. This allocation, one of the highest ever, underscores the government’s intent to sustain momentum in large-scale infrastructure creation, spanning highways, expressways, metro rail systems, railways, ports, airports, industrial corridors and logistics infrastructure. Each of these segments is inherently cement-intensive, ensuring steady volume absorption for the industry over the execution cycle of projects. Beyond headline capex, the sharp increase in Grants-in-Aid for the creation of capitalassets significantly lifts effective public investment. When combined, total effective capital expenditure rises well above ₹17 lakh crore, materially expanding the addressable construction pipeline. This enhanced spending capacity is expected to translate into improved project execution, reduced bottlenecks and faster rollout of infrastructure projects, thereby supporting consistent cement offtake rather than sporadic demand spikes.

A key structural support for execution comes from the substantial increase in fiscal transfersto states, which have been raised to ₹25.43 lakh crore in FY27. This decentralisation of financial resources empowers state governments and urban local bodies to accelerate infrastructure and redevelopment initiatives tailored to local needs. For the cement sector, this is particularly important, as state-led projects such as metro rail networks, urban road upgrades, water and sewage systems, and regional highways tend to be geographically dispersed and execution-heavy, creating stable and diversified demand.

Housing remains a central pillar of cement consumption, and the Budget reinforces this segment across both rural and urban markets. Higher allocations for PMAY-Gramin are expected to support rural housing construction, a segment that contributes nearly 35–36% of total cement demand. Improved farm incomes, aided by higher rural development and agriculture spending, are likely to enhance affordability and sustain construction activity in semi-urban and rural regions. Urban housing has also received renewed policy impetus. Increased funding for PMAY-Urban, combined with the government’s focus on Tier II and Tier III cities, is expected to broaden the base of housing-led cement demand beyond the top metropolitan centres. The proposed City Economic Regions (CERs), backed by multi-year funding commitments, are likely to catalyse integrated development across housing, transport, commercial infrastructure and urban services, further strengthening cement consumption over the medium term.

The Budget’s emphasis on tourism, cultural and social infrastructure adds another dimension to construction activity. Investments in heritage redevelopment, tourism facilities, Buddhist and cultural circuits, regional connectivity in Purvodaya and the North-Eastern states, as well as the strengthening of district-level healthcare and trauma care infrastructure, will generate construction demand across underpenetrated regions. While these projects are smaller in scale compared to mega infrastructure works, their wide geographic spread makes them cumulatively significant for cement volumes. A major structural reform benefiting the sector is the reduction in the GST rate on cement from 28% to 18%, addressing a long-standing industry concern. Cement had remained among the highest-taxed essential building materials, despite its foundational role in infrastructure and housing. The rationalisation restores parity with other core construction inputs, improves affordability, and enhances the competitiveness of Indian cement producers, particularly in price-sensitive segments such as affordable housing and rural construction.

Taken together, the combination of ₹12.2 lakh crore in capital expenditure, higher effective public investment, decentralised state spending, strong housing support and tax rationalisation creates a favourable policy environment for the cement industry. These measures not only support near-term demand but also provide durable visibility for growth over the next three to five years, firmly positioning cement as a cornerstone of India’s infrastructure-led development trajectory.

The Road to Structural Growth

What was once an occasional feature of the cement industry has now become a defining trend. Over the past few years, mergers and acquisitions have emerged as a preferred route for expansion, driven by the need for rapid scale, regional diversification and operational efficiencies. This consolidation cycle effectively began in September 2022, when the Adani Group entered the cement sector by acquiring controlling stakes in Ambuja Cements and ACCfrom Switzerland-based Holcim in a landmark USD 10.5 billion transaction. Following this entry, the Adani Group moved swiftly to expand its cement footprint through a series of acquisitions. This included the acquiring Sanghi Industriesin 2023, Penna CementIndustriesJune 2024), and Orient Cementin October 2024. These acquisitions significantly strengthened the Group’s presence across western, southern and eastern India, while adding meaningful capacity and limestone reserves. The Adani Group has approved the consolidation of its cement operations under a single corporate structure. As part of this strategy, ACC and Orient Cement are proposed to bemerged into Ambuja Cements, creating a unified “One Cement” platform. This consolidation fits well with the Group’s broader strategy of emerging as a leading player across infrastructure verticals, enabling tighter integration with its ports, logistics, power and construction businesses. The move is expected to simplify the operating structure, unlock synergies across procurement, logistics and distribution, improve capital efficiency, and reinforce the Group’s long-term commitment to the cement sector.

UltraTech Cement, the country’s largest cement manufacturer, has pursued a steady and methodical acquisition-led strategy to reinforce its market leadership and deepen its regional presence. In 2024, the company acquired a 32.72% stake in India Cements from its promoters for ₹3,954 crore, following an earlier 23% stake purchase in June the same year. Together, these transactions raised UltraTech’s shareholding beyond 55%, giving it majority control and strengthening its foothold in the southern markets. This followed the acquisition of Kesoram Industries’ cement assets in November 2023 for ₹7,600 crore, which added 10.75 MTPA of capacity and further consolidated UltraTech’s scale in South India. In December 2023, the company also acquired the cement grinding assets of Burnpur Cement for ₹169.79 crore, enhancing its operational flexibility. Beyond core cement capacity, UltraTech has selectively expanded its geographic reach and product portfolio. In December 2024, it agreed to acquire an 8.69% stake in Star Cement for ₹851 crore to strengthen its presence in the North East, while in April 2025 it completed the 100% acquisition of Wonder WallCare for ₹235 crore, reinforcing its push into value-added and branded building solutions.

As the renewed thrust on infrastructure development continues to create a more attractive demand environment for the cement sector, companies have increasingly turned to brownfield expansion as a faster and lower-risk route to capacity addition. Rather than committing large capital to greenfield projects with longer gestation periods, manufacturers are selectively acquiring existing assets to strengthen regional presence and accelerate market access. JK Cement, for instance, completed the acquisition of a 60% stake in Srinagar-based Saifco Cements for ₹150 crore, marking a strategic entry into the Jammu & Kashmir market and providing immediate operational capacity in a region with growing infrastructure and housing demand. Similarly, K Cement acquired 100% equity shareholding in Toshali Cements, headquartered in Hyderabad, for ₹157 crore, enabling the company to expand its footprint in southern India and leverage established assets to support near-term growth. JK Lakshmi Cement has also pursued targeted acquisitions as part of its broader growth and portfolio-strengthening strategy. The company acquired Agrani Cement in February 2024, followed by the acquisition of Hidrive Developers & Industries in September 2023, enabling it to augment capacity and expand its regional footprint through existing operational assets. Further underlining its intent to deepen its presence in high-growth southern markets, JK Lakshmi Cement was reported to be in discussions in July 2025 to acquire Telangana-based Deccan Cements, a move that would provide incremental capacity and strategic access to a key demand centre in South India. Nuvoco Vistas Corporation has successfully completed the acquisition of Vadraj Cement under the corporate insolvency resolution process (CIRP). The transaction was finalised on 2025, following a payment of ₹1,800 crore to the company’s lenders, led by Punjab National Bank and Union Bank of India.

Q3 FY26: Navigating the Ups and Downs

In Q3 FY26, the Indian cement sector operated in a challenging environment marked by persistent cost pressures, subdued pricing power and uneven demand execution. Volatility in fuel and energy costs weighed on margins, while intense competition and recent capacity additions—especially in the East, Central and Southern regions—kept realisations under pressure. Infrastructure demand offered underlying support, though state-level execution remained uneven and weather-related disruptions impacted offtake in select markets. Against this backdrop, performance across companies diverged. UltraTech Cement stood out with a strong showing, reporting a 32% year-on-year rise in consolidated net profit (before exceptional items) to ₹1,792 crore, supported by 22.5% revenue growth to ₹21,506 crore, around 15% domestic grey cement volume growth and improved cost efficiencies, which lifted EBITDA to ₹4,051 crore and EBITDA per tonne to ₹1,051. ACC and Ambuja Cements delivered mixed results despite healthy volume growth. ACC’s net profit declined 63% YoY to ₹404 crore even as revenue rose 21.7% to ₹6,391 crore, while Ambuja’s profit fell to ₹367 crore despite a 20% increase in revenue to ₹10,180 crore, with higher input and operating costs compressing margins. JSW Cement reported a sharp turnaround, with net sales rising 8.7% to ₹1,478.7 crore and net profit surging to ₹149.5 crore, aided by strong EBITDA growth of nearly 88% YoY. J K Cement posted solid growth, with net sales up 18.2% to ₹3,463 crore, EBITDA rising to ₹558 crore and profit after tax increasing to ₹174 crore on improved utilisation and cost control. JK Lakshmi Cement reported moderate revenue growth of 6.1% to ₹1,588 crore, though net profit declined to about ₹57 crore amid higher costs, even as volumes supported EBITDA at ₹234 crore.

Navigating Cyclical Pressures to Structural Growth

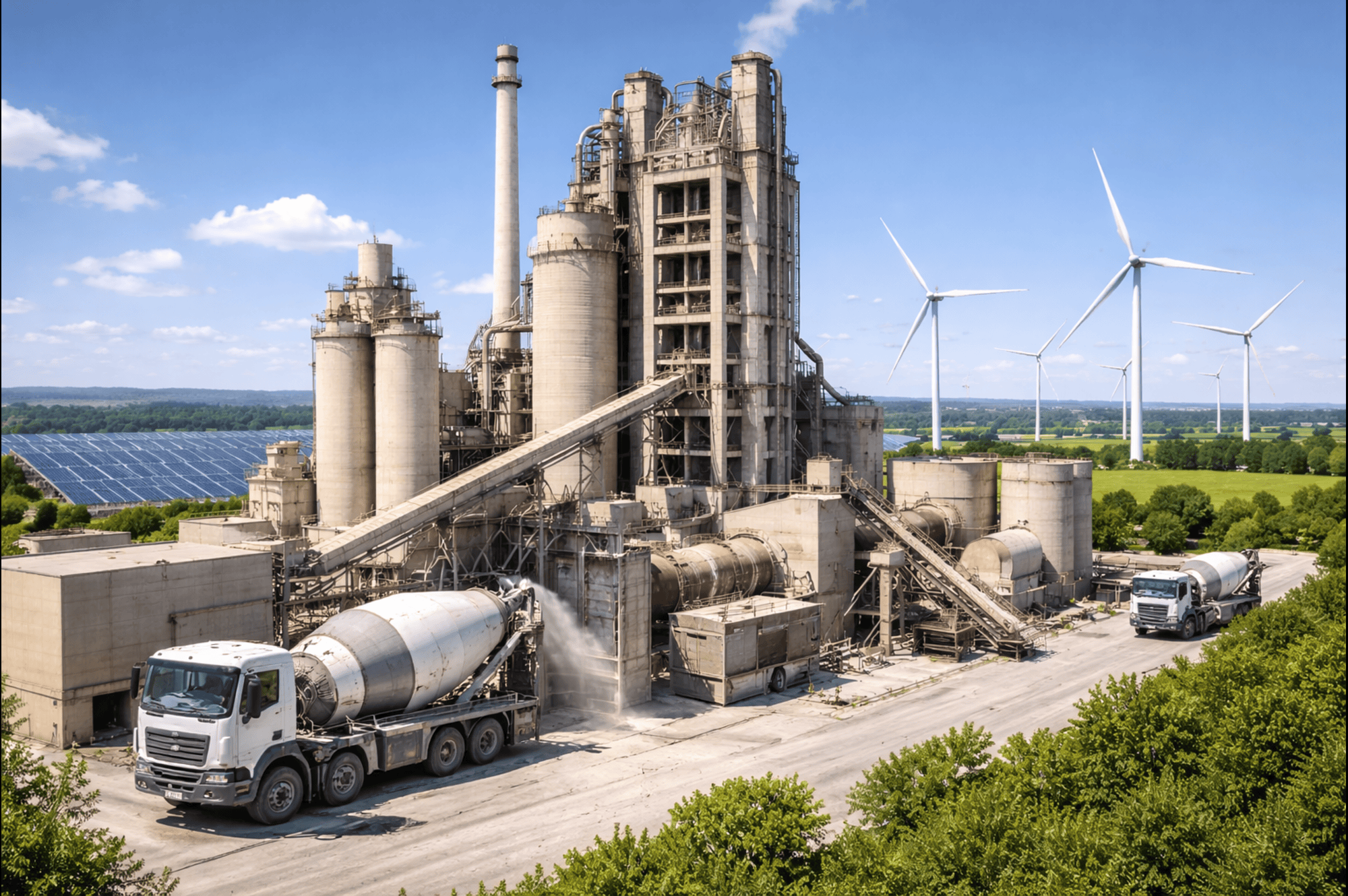

The Indian cement sector is at an inflection point, with near-term challenges running alongside strong medium- to long-term opportunities. Elevated capacity additions over the past two years have intensified competition, particularly in the East, Central and Southern regions, constraining pricing power despite a gradual demand recovery. Cost volatility -especially in fuel, power and freight – continues to weigh on margins, while uneven state-level project execution, weather disruptions and working capital pressures pose near-term risks, particularly for mid-sized players. Offsetting these headwinds are robust structural demand drivers. Sustained public infrastructure spending, expanding housing demand across urban and rural markets, and rising private investment in industrial and logistics assets provide strong volume growth visibility. Policy support through higher capital expenditure, increased focus on Tier II and Tier III cities, and the development of City Economic Regions further strengthens the long-term outlook. Sector consolidation is also improving scale efficiencies, cost competitiveness and balance sheet resilience for larger players. In parallel, the industry’s growing focus on sustainability—through alternative fuels, waste heat recovery, green power and higher clinker substitution – offers a pathway to structurally lower costs while advancing decarbonisation goals. Going forward, success will hinge on disciplined capacity expansion, efficient execution and effective cost management.

On a Steadier Growth Path

Looking ahead, cement demand is expected to remain on a firm footing, underpinned by sustained public infrastructure spending, continued momentum in housing across both urban and rural markets, and rising investments in industrial and logistics infrastructure. Large-scale projects across roads, railways, metros, urban redevelopment and industrial corridors are likely to ensure steady volume growth over the next few years. While near-term pricing pressures may persist due to elevated capacity additions and intense regional competition, improving capacity utilisation, operating leverage and ongoing cost-efficiency initiatives – such as greater use of alternative fuels, green power and logistics optimisation -should support a gradual recovery in profitability over the medium term, particularly for well-capitalised and efficient players.

Tags