Beyond Fuel: How green hydrogen will redefine India’s industrial backbone

by AK Tyagi, Founder & CMD, Nuberg Group of Industries

This article explores how green hydrogen is reshaping India’s industrial landscape — driving decarbonisation, strengthening energy security, and boosting competitiveness across sectors like steel, fertilisers, and chemicals. It also outlines India’s roadmap under the National Green Hydrogen Mission and how engineering and EPC expertise are translating policy goals into large-scale industrial action

India stands at a historic crossroads. As the nation’s growth trajectory accelerates, its industries — from fertilizers to steel, hydrocarbons to chemicals — are under scrutiny. The traditional reliance on fossil fuels and carbon-intensive feedstocks is no longer endurable, either economically or environmentally. Into this moment steps green hydrogen, not just as an alternative fuel, but as a transformative force capable of redefining the very structure of India’s industrial backbone.

The National Green Hydrogen Mission, targeting five million tonnes of production annually by 2030, provides the strategic backbone to India’s ambitions. This initiative is not merely a climate compliance exercise; it is a blueprint for industrial transformation. With rapid advancements in electrolyser technology, green hydrogen is steadily narrowing the cost gap with conventional grey hydrogen. Simultaneously, global markets are placing a premium on low-carbon products, opening export opportunities and compelling Indian industries to adopt future ready standards.

Green hydrogen, therefore, is more than decarbonisation. It is about energy security, reduced import dependency, industrial competitiveness, and strategic autonomy. Beyond fuel substitution, it enhances India’s credibility in climate commitments while creating a platform for industrial innovation across sectors. Additionally, this platform is growing to include green methanol, green ammonia, and even compressed biogas (CBG)—fuels and feedstocks that are not merely “alternatives,” but rather the foundation of an entirely new industrial economy.

Few sectors will remain untouched by this transition such as:

Fertilizer Production: Large amounts of hydrogen is used in ammonia production. Switching to green hydrogen — and in time, green ammonia — could significantly lower carbon footprints while opening access to export markets that require certified low-carbon fertilizers.

Refineries: Clean fuels and desulfurization depend on hydrogen. Green hydrogen and green methanol pathways increase resilience while enabling compliance with stricter emission standards. Several global refiners are piloting such approaches, and Indian refiners are beginning to follow suit.

Steel: One of the industrial processes that emits the most carbon is still the production of steel. Green hydrogen-powered Direct Reduced Iron (DRI) production can take the place of coal and reduce CO₂ emissions by more than 70% during the reduction phase alone. A roadmap for India’s steel hubs has been provided by several international steelmakers who have shown pilot projects in which hydrogen is used in place of coke.

Chemicals & Specialty Intermediates: Green hydrogen paves the way for next-generation industrial chemistry, from hydrogenation reactions to the production of methanol and specialty chemicals. India has the potential to develop into a center for the production of high-value, low-carbon intermediates for both export and domestic markets as hydrogen-derived feedstocks gain popularity.

The ripple effect extends further. Green derivatives such as green ammonia and green methanol are gaining traction in shipping and aviation fuels, enhancing India’s export competitiveness. Industries that adopt these solutions early will set global benchmarks, positioning the country as a hub for clean industrial feedstocks.

Hydrogen is transforming industries globally, with Europe, Japan, and South Korea investing heavily to boost competitiveness and energy security. India can leverage policy support, R&D incentives, and global best practices to accelerate adoption while tailoring solutions to domestic energy, costs, and industrial needs.

Pilot projects, demonstration plants, and early-stage hydrogen hubs are proving grounds for testing feasibility, improving supply chain integration, and building investor confidence. While proprietary details remain confidential, these initiatives illustrate how India can gradually scale green hydrogen solutions across industrial clusters. Despite the promise, challenges remain. Significant obstacles include the high initial capital costs of electrolysers and hydrogen storage, the erratic nature of renewable energy sources, and the infancy of transportation networks. Industrial offtake commitments are still in their infancy, and policy frameworks pertaining to certification, safety, and market mechanisms are still developing.

At the same time, global technology trends are highlighting the importance of the Balance of Stack (BoS) — the suite of components that determine the efficiency, scalability, and reliability of electrolyser systems. The world is witnessing billion-dollar investments in BoS capabilities, and India has the chance to leapfrog in this area. Major BoS projects are already underway, signalling that this is no longer niche technology but a central pillar of the hydrogen economy.

Engineering the transition

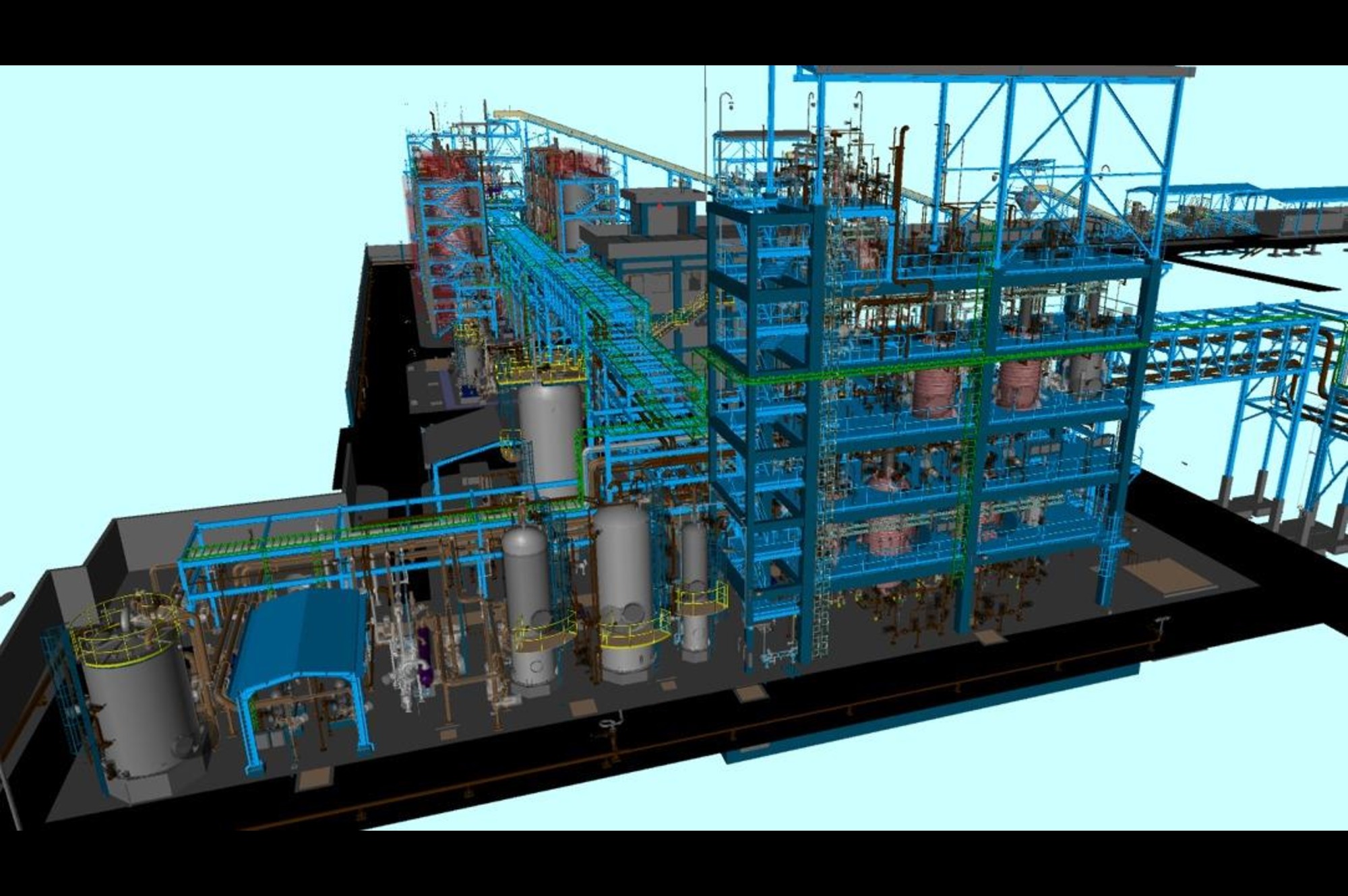

Execution is where policy ambition meets industrial reality. Designing, building, and operating integrated hydrogen projects at scale demands deep engineering expertise – spanning electrolysers, storage, purification, and integration — as well as specialised

capabilities as a Green NH₃ EPC contractor for ammonia projects. This is where Green Hydrogen Engineering Companies & EPC Contractors with proven capabilities will play a central role in bridging vision with reality.

At Nuberg Green Energy, we have already embarked on this journey. With over two decades of global hydrogen experience, we have been at the forefront of several milestones — from engineering India’s first hydrogen refuelling station in Vadodara for IOCL, to executing green hydrogen plants, green ammonia and green methanol facilities, advanced hydrogen purification units, and Balance of Stack-enabled systems. Beyond project execution, we also provide in-house engineering and specialised equipment manufacturing for electrolysers, BoS units, storage systems, and integrated hydrogen plants. We are also advancing CBG projects as part of an integrated clean fuels portfolio.

This breadth of capability positions Nuberg not just as a leading green H₂ EPC contractor but also among India’s foremost green hydrogen manufacturing companies, delivering solutions that combine renewable integration, process efficiency, and industrial scalability. Our approach underscores the importance of merging engineering innovation with operational pragmatism, ensuring that India moves seamlessly from pilot initiatives to large-scale industrial adoption.

Green hydrogen is a strategic economic tool, helping India reduce fossil fuel imports, stabilise industrial costs, and tap into low-carbon export markets. Early adoption offers competitive advantage, reshapes global supply chains, and drives job creation across EPC, renewables, and advanced chemical sectors.

The Way Forward

India’s green hydrogen transition goes beyond replacing fuels — it’s about reshaping industries, value chains, and competitiveness. Success requires clear policies on certification and incentives, innovative financing to reduce capital risks, robust EPC capabilities (as demonstrated by Nuberg Green Energy’s global experience), and international collaboration. Together, these efforts can make green hydrogen the backbone of India’s industrial growth, decarbonisation, and global competitiveness.

Tags