Ammonium nitrate’s role in mining and infrastructure

by Tarun Sinha, President – Technical Ammonium Nitrate, Deepak Fertilisers and Petrochemicals Corp

Mining and Infrastructure sectors in India contribute heavily to the development and growth of Indian economy. Government of India (GoI) has recognized the critical role of these sectors towards faster growth to meet the target of $5 trillion economy in the next few years.

Technical Ammonium Nitrate (TAN) is the principal ingredient of most commercial explosives required for mineral and rock blasting in the mines, stone quarries and infrastructure projects to produce Coal for Power generation, Iron-ore for Steel production, Limestone for Cement production, Stone aggregates for use in Construction works, and recovery of other critical minerals/metals such as Aluminium, Lead, Zinc, Gold, Silver, Copper, Barytes, Manganese, Uranium, Lithium, etc.

Domestic capacities of technical ammonium nitrate

India currently has 13.5 LTPA production capacity of Ammonium Nitrate. Further 7.8 LTPA greenfield capacity has been committed most of which will be operation by 2026/27, totalling 21.3 LTPA domestic capacity, which will make India Atmanirbhar for its Ammonium Nitrate needs to support the growth in Mining and Infrastructure sectors of the economy.

Application of technical ammonium nitrate in rock blasting

TAN is manufactured in Solid and Liquid forms. It has the chemical formula NH4NO3. It is an “oxidiser” which contains approximately 60% oxygen and, therefore, supports combustion. TAN is not an explosive by itself. Commercial explosives are produced by mixing TAN with fuel and sensitizer. These commercial explosives, when used with other blasting agents like detonators and boosters, are rapidly converted into gases at high temperature and pressure in a confined state in the rock, leading to breaking of the rock/mineral.

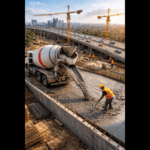

The broken rock/mineral is then put to its intended use after further processing as may be required, e.g., broken stone is used as stone chips for Infrastructure construction, broken limestone is used for cement production, broken iron ore is used for steel production, and broken coal is used for thermal power generation.

Blasting efficiency determines mine productivity and mineral extraction cost

Blasting activity has a significant impact on the downstream value chain in the mineral and rock production and extraction process. Improvement in blasting efficiency has a multiplier effect on the downstream process. Blasting efficiency is a factor of type of explosives used (based on the rock/mineral and associated geological conditions), and deployment of advanced technologies such as blast design, real-time measurement of blast outcomes, eg, rock fragmentation (correct sizes of blasted rock output enables faster excavation and also aids in improving crusher throughput), control in dilution (purity factor), vibration and noise control, blasted material profile etc. Drones and Artificial Intelligence are used to accurately analyse, simulate, and predict the results for improved safety and productivity.

ANFO – Specialty explosives

TAN in Solid and Liquid forms is used to manufacture different types of commercial Explosives.

One specialty explosives called as Ammonium Nitrate-Fuel Oil (ANFO), is a widely used explosives which is manufactured through use of ~94% of porous prilled TAN and ~6% fuel oil such as diesel. With this 94%/6% TAN/Diesel blend, ANFO is the purest form explosives which has a higher share of gas energy that leads to better fragmentation of mineral/stone aggregates which in turn leads to reduced excavation and transport cost of the broken minerals/stone aggregates eventually delivering improved productivity of heavy earth moving machinery (HEMM), reduced crusher power consumption and reduced wear and tear (hence improved maintenance cost) of the crusher.

ANFO explosives coupled with the use of advanced technologies mentioned above, enables faster throughput thereby speeding up infrastructure development in India, besides the cost savings and control over environmental parameters such as vibration, fly-rock, noise, etc. which are becoming more critical in view of mandate over ESG that the govt. and construction companies need to adhere to.

Benefits of ANFO in mining applications have been established across the World and in India by independent research and technical bodies like CIMFR, CMPDIL, NIT Rourkela, etc. and more Mines and Infrastructure projects are shifting towards use of ANFO to take advantage of the commercial (through reduction in rock/mineral extraction cost) and environmental (through reduction of environmental nuisances) benefits offered by ANFO.

Conclusion

Technical Ammonium Nitrate will continue to play a pivotal role in meeting India’s demand for power generation and infrastructure construction, which are set to grow with the increasing population and the improving standards of living.

Specialty explosives “ANFO” produced from Technical Ammonium Nitrate will enable faster mining, construction & infrastructure progress, and at improved productivity levels, which would be integral to supporting India’s economic growth in the decades to come.