Ambuja supplied 3.17 lakh tonnes of cement for the Chenani-Nashri tunnel

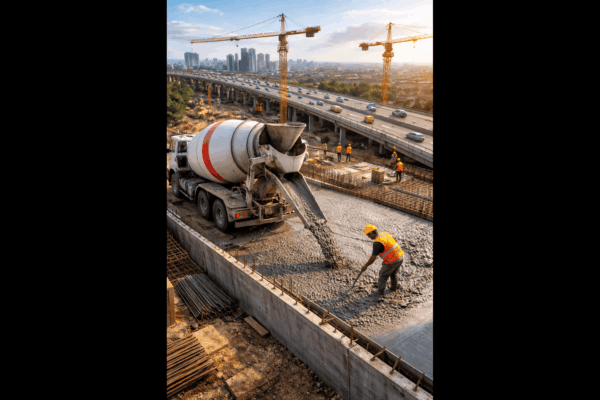

Ambuja Cement has once again reinforced its strong commitment towards nation building by playing a vital role in the construction of Chenani-Nashri road tunnel in Jammu and Kashmir. The world class infrastructure project is India's longest (9 km long) road passageway with state-of-the-art urban transport facilities.

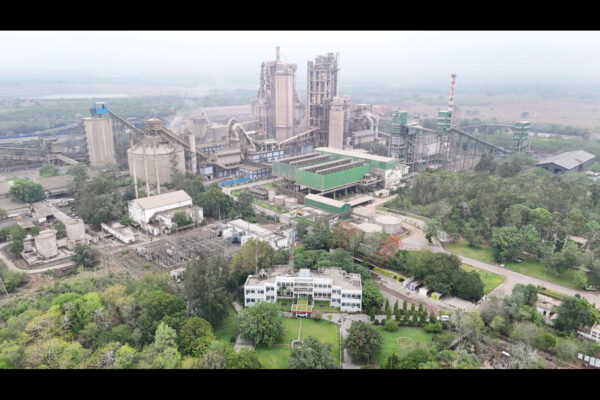

Ambuja Cement’s Ropar unit supplied 3.17 lakh tonnes of high quality cement for this project, developed by executing agency IL&FS Transportation Networks Ltd (ITNL). Ambuja Cement’s Technical Services teams provided complete technical support for this venture, demonstrating its strong manufacturing prowess combined with swift technical assistance.

Commenting on the occasion, Ajay Kapur, Managing Director and CEO, Ambuja Cement said, “It is a proud moment for all of us at Ambuja Cement to be a key partner of the world class Chenani-Nashri tunnel in Jammu and Kashmir, thus contributing to India’s growth story. Our participation in this ambitious venture goes a long way in reiterating our nation’s building vision. We are happy to be part of this landmark infrastructure and are confident that this all-weather road project will bring relief to thousands of commuters in the northern state.”

The new tunnel stretches from Chenani (Udhampur district) to Nashri (Ramban district) town. The tunnel project reduces the 41 km route through steep and hilly terrain to a highway of less than 10 km. This project is part of the development of the new alignment section of NH 1-A which includes the 9 km single tube bi-directional tunnel with a parallel intermediate lane escape tunnel of 29 cross passages.

The tunnel will enable sustainable transport through fuel saving of Rs.27 lakh per day by cutting down commute time. It will make road travel safer and reduce traffic disturbances caused by unpredictable land-slides, sharp-turns, vehicle breakdowns and accidents. The new tunnel is secured with a robust security and a three-tier power back-up system.

ITNL also plans to install a Display Museum near the tunnel entrance and has solicited Ambuja Cement to extend its technical prowess for the extended project. Ambuja’s Technical Services team is currently consulting ITNL to charting out a roadmap for developing this unique museum.

By EPC World Media Group