Advancing Water Quality Control in Semiconductor Manufacturing: METTLER TOLEDO’s Precision Approach

As India advances toward becoming a global semiconductor manufacturing hub, ultrapure water (UPW) management has emerged as a critical factor in achieving high process yields and reliability. Maintaining contaminant-free environments demands real-time, high-precision monitoring of water quality at every stage of fabrication. METTLER TOLEDO, a leader in analytical instrumentation, delivers advanced solutions for conductivity and TOC analysis—enabling semiconductor fabs to ensure consistent water purity, minimize defects, and enhance overall manufacturing efficiency

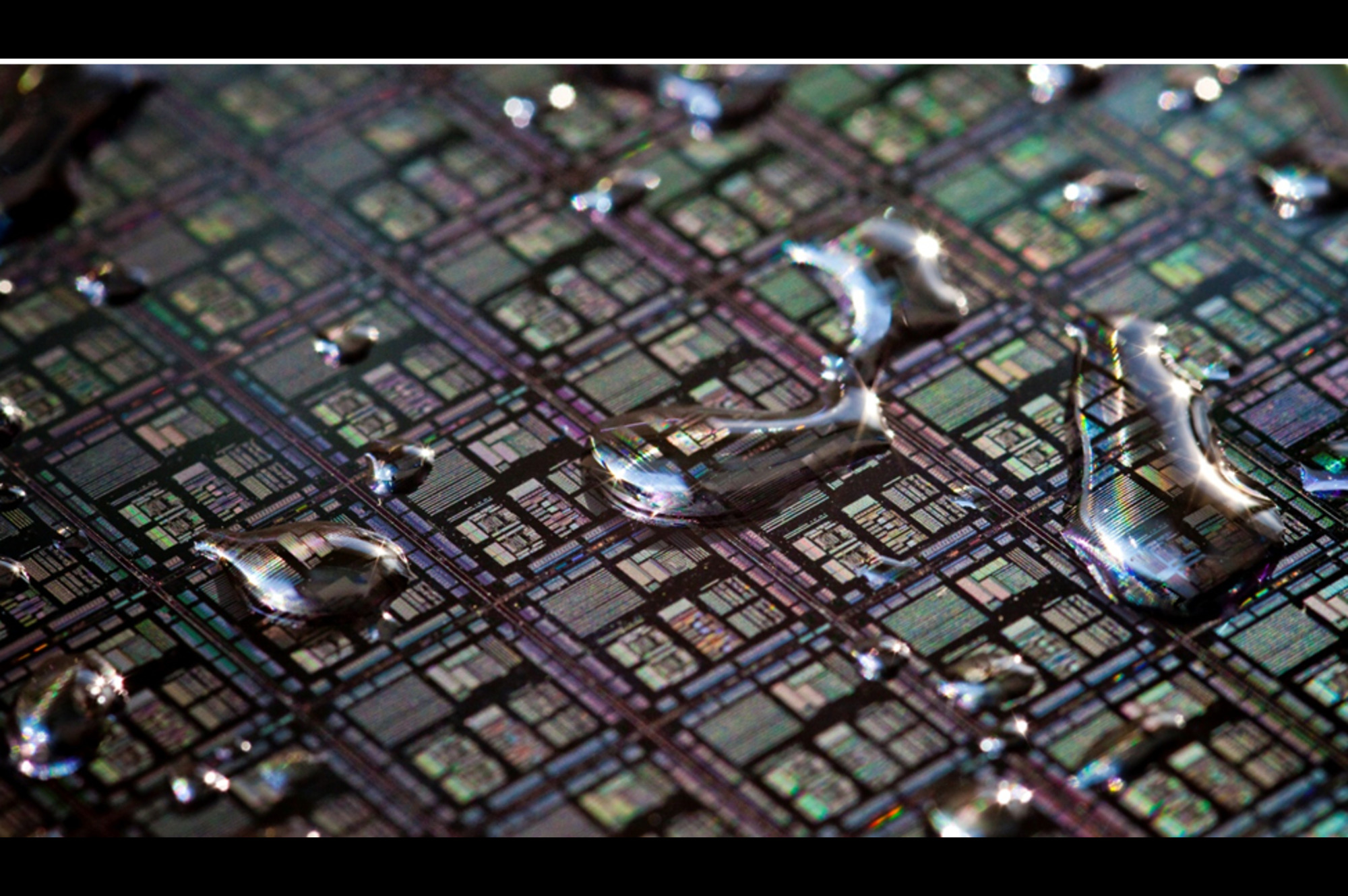

Semiconductors are the foundation of today’s digital economy, powering innovations in smartphones, electric vehicles, AI, and cloud computing. As the push for smaller, faster, and more efficient chips accelerates, semiconductor fabrication demands exceptional precision and purity. At the core of this process is ultrapure water (UPW)—vital for wafer cleaning, rinsing, and polishing to eliminate microscopic contaminants.

India’s emerging semiconductor industry is aligning with global standards, where stringent UPW management is critical to ensuring process reliability and high production yields. This requires real-time, high-accuracy monitoring and control of key water quality parameters—such as conductivity, silica, dissolved oxygen, and total organic carbon (TOC) etc to maintain the ultra-clean environments essential for advanced chip manufacturing.

Conductivity Monitoring for Ultrapure Water:

The purity of UPW is measured by its conductivity, which must be as low as 0.055 µS/cm (or 18.2 MΩ·cm) to ensure minimal ionic contamination. METTLER TOLEDO advanced conductivity sensors provide highly reliable and accurate measurements, crucial for continuous monitoring of UPW feed systems in semiconductor fabs. This ensures the water used in cleaning and cooling processes consistently meets stringent purity requirements, directly impacting chip quality and yield.

TOC Analysis for Organic Contamination Control:

Total Organic Carbon (TOC) levels must be meticulously controlled, often below 1 part per billion, to prevent defects in sensitive processes such as photolithography. METTLER TOLEDO 6000TOCi sensor paired with the M800 transmitter offers continuous, real-time, low-maintenance online TOC measurement. Equipped with Intelligent Sensor Management (ISM), this system provides advanced diagnostics and ensures optimal sensor performance, minimizing downtime and maintenance costs.

By integrating METTLER TOLEDO conductivity and TOC analysers, India’s semiconductor industry can achieve precise water quality control, enhancing manufacturing efficiency, reducing defects, and boosting overall productivity. Our solutions support the semiconductor industry’s quest for excellence and reliability in a rapidly advancing technological landscape.

Explore more: https://www.mt.com/in/en/home/industries/semiconductor-manufacturing.html

Tags