Kayan Kalthia, Director – Business Development, Kosol Energie

While execution challenges remain in the short term, we are positive about the direction of policy and infrastructure development

What new technologies or products are you showcasing at the exhibition, and how do they improve efficiency, cost or performance for customers?

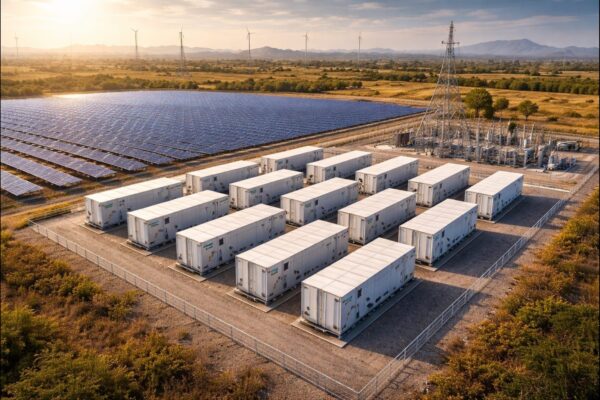

At the exhibition, we are showcasing our partnership with Kosol and GridScape, featuring an advanced AI-driven microgrid platform. This microgrid sits on top of all the customer’s available energy sources – such as solar, grid power, diesel generators, and storage – and uses AI to continuously analyze demand patterns, weather forecasts, tariff structures, and asset performance. Based on this, it automatically selects the most optimal energy mix to deliver the lowest possible LCOE, while improving reliability and overall energy efficiency. In addition, we will be presenting our latest Battery Energy Storage System (BESS) offerings, which will soon be available to customers. These include storage solutions ranging from 150 kWh and 300 kWh up to 7 MWh with indigenous BMS and EMS, enabling customers to reduce peak demand charges, increase renewable energy utilization, improve backup power capability, and enhance grid independence – all while optimizing cost and performance.

Solar panel prices have fluctuated lately. How are raw material costs, module prices and global supply dynamics impacting your pricing and competitiveness in India?

It’s true that solar panel prices have seen some volatility recently, driven mainly by fluctuations in raw material costs such as copper, silver, aluminum, and wafers, along with broader global supply-chain dynamics. These factors have led to some increase in overall module pricing across the industry. However, since this impact is industry-wide, it does not materially affect our competitiveness in the Indian market. All major manufacturers and suppliers are facing similar cost pressures. What differentiates us is our strong supplier partnerships, efficient procurement strategies, and optimized system design, which help us manage costs and pass on the most competitive pricing possible to customers while maintaining quality and performance. Despite short-term price movements, we continue to see strong long-term fundamentals for solar in India, supported by scale, localization, and improving efficiency across the value chain.

What progress are you making in manufacturing localisation in India? How critical is domestic manufacturing for future cost stability and supply security?

We are making strong progress on manufacturing localisation in India, particularly through strategic tie-ups for key raw materials used in solar panel manufacturing. At the same time, we are actively working toward localising as many components as possible across the entire solar EPC value chain. A major area of focus for us is Battery Energy Storage Systems (BESS), where localisation can have a significant impact – not just on cost, but also on availability, lead times, and long-term serviceability. From a cost perspective, we believe India will remain globally competitive as manufacturing scale and efficiency continue to improve. However, more critical than cost alone is supply security. Recent global disruptions have clearly shown that domestic manufacturing is essential to ensure predictable supply, reduce dependency on imports, and support the long-term growth of the renewable energy sector in India. This is why localisation is a strategic priority for us—not just as a cost lever, but as a foundation for resilience and reliability in the years ahead.

In a market with rising competition, how do your solutions stand apart? What value do you deliver that differentiates you from other players here?

In an increasingly competitive market, what truly sets our solutions apart is consistent quality and a deep focus on end-user value. We don’t take a one-size-fits-all approach. Instead, we work very closely with customers to maximize the actual earnings and returns from their renewable energy projects – whether the customer is a homeowner, farmer, developer, or an EPC partner. Our focus goes beyond just supplying equipment. We look at system design, performance optimization, reliability, and long-term outcomes, ensuring that each project delivers the best possible financial and operational results over its lifetime. Backing this approach is over a decade of proven experience as Kosol Energie, with a strong track record of performance across diverse applications and geographies. That history, combined with our emphasis on quality, trust, and customer outcomes, is what consistently differentiates us from other players in the market.

What emphasis do you place on after-sales service, warranties and O&M support? How crucial is service quality for gaining customer trust?

After-sales service is a core pillar of our approach, not an afterthought. Our first priority is always to deliver a “first-time-right” system – with robust design, quality components, and proper commissioning – so that ongoing O&M requirements are minimal from the start. Where O&M is required, we either manage it directly or provide the customer with a clear, structured O&M plan, ensuring transparency and ease of operation. We also stay in regular touch with customers, monitoring system performance and addressing issues proactively to ensure long-term reliability and output. Service quality is extremely crucial for earning and sustaining customer trust, especially in renewable energy where performance is realized over many years. Our focus has never been just customer satisfaction, but customer delight – by being responsive, dependable, and committed to the system’s performance throughout its lifecycle.

How are digital tools – like AI monitoring, remote controls and data analytics -shaping the performance and maintenance of solar plants?

Digital tools such as AI-based monitoring, remote controls, and data analytics are shaping solar plant performance and maintenance in a very significant way. At Kosol Energie, we plan to actively leverage our historical data and past project performance to demonstrate our pedigree and long-term reliability, while also using analytics internally to identify gaps, improve processes, and continuously enhance system performance.

These tools also play a critical operational role by helping us detect issues early, pinpoint exactly where problems are developing, and assign clear accountability, enabling faster resolution and reduced downtime. Looking ahead, we believe wider availability and transparency of performance data across the industry will benefit customers as well. Access to reliable data and analytics empowers end users to make more informed decisions when choosing suppliers and long-term partners, ultimately raising standards across the renewable energy ecosystem.

What are the major challenges companies face in executing solar projects today – land availability, grid connection, approvals, logistics, etc?

Today, the two biggest challenges in executing solar projects are land availability and timely grid connectivity. Securing suitable land – especially at scale – and coordinating right-of-way and evacuation infrastructure often create delays and cost uncertainty. That said, the recent budget announcements have been very supportive, particularly in addressing grid infrastructure expansion and streamlining processes related to land and connectivity. These steps give us confidence that many of the current bottlenecks will ease over time. Overall, while execution challenges remain in the short term, we are positive about the direction of policy and infrastructure development, and we expect a much smoother project environment going forward.

Tags