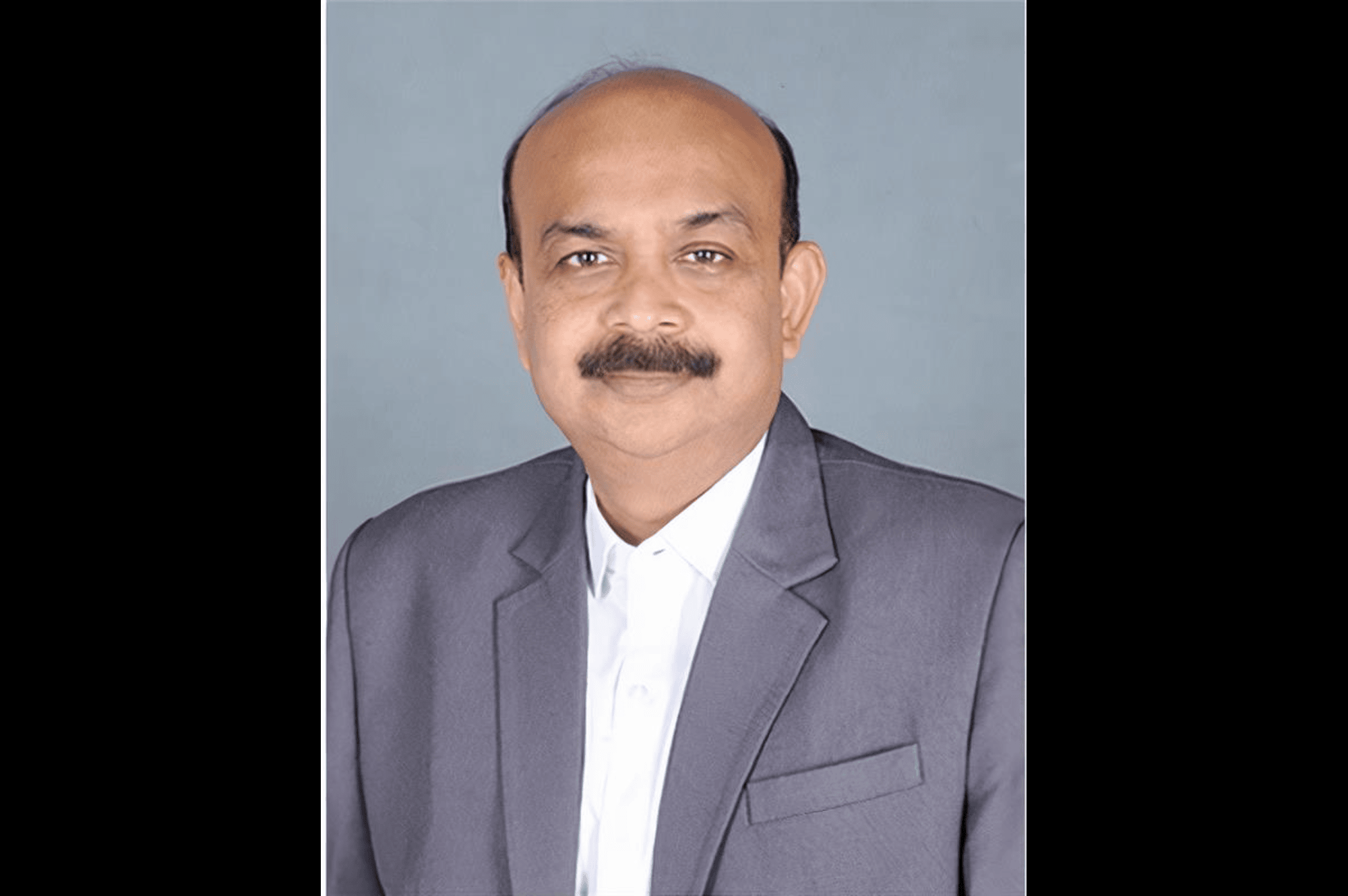

Interview: M T Swamy, Director – Sales, Kennametal India

The objective is to engage with our customers directly — to understand their evolving requirements and challenges, so that we can continue innovating with new grades, designs, and technologies that deliver real-world solutions to the market

Can you elaborate on the core focus areas for Kennametal and the next-generation manufacturing solutions you are showcasing at IME 2025?

Kennametal’s focus at this Exhibition is on driving growth in the mining sector, particularly iron ore. As you know, the Government of India has set an ambitious target to achieve 1,500 million metric tonnes of production by 2030. With this, we’re witnessing significant expansion in the mining industry — not just among government-owned mines, but also with the rise of commercial mining operations. So, the outlook for mining in India till 2030 is very promising. At Kennametal, our focus here is twofold. First, we are showcasing our latest products and next-generation solutions designed to help customers enhance productivity, reduce costs, and ensure reliable operations. The second objective is to engage with our customers directly — to understand their evolving requirements and challenges, so that we can continue innovating with new grades, designs, and technologies that deliver real-world solutions to the market.

Could you please explain how your products contribute to improved safety, better working conditions, and higher productivity across mining operations?

At IME, we are showcasing several new products designed to enhance safety, productivity, and reliability in mining operations. For underground mining, we’ve introduced advanced conicals and block systems, while in surface mining, we are launching a new grade called PlusPoint — an extra-tough grade engineered to deliver higher productivity and longer life. We are also displaying motor grader blades for haul road maintenance and our KenCast solutions, which were launched a couple of years ago and continue to deliver excellent results in the field. All these innovations are aimed at improving operational efficiency, reducing downtime, and enhancing safety across mining sites.

Beyond mining, Kennametal has been a key enabler of productivity in multiple industries, including steel, power, petrochemicals, automotive, and food processing. Wherever there are wear-related challenges, we provide advanced tungsten carbide and related solutions. In mining, specifically, our approach to boosting productivity is twofold. First, through material science, we continuously develop new grades — such as PlusPoint — based on customer feedback to offer superior toughness and wear resistance. Second, through design innovation, we engineer conicals and tooling systems tailored to specific mining conditions, optimising wear performance and tool life. Together, these efforts ensure safer, more efficient, and cost-effective mining operations for our customers.

Are the products showcased at IME 2025 manufactured in India?

Currently, most of our products are not manufactured in India. However, as the Indian mining market continues to grow, we are actively evaluating the possibility of local production. We already have a facility in India with complete end-to-end manufacturing capability — from powder processing to finished goods. At present, the production volumes do not justify local manufacturing from an economic standpoint. But as business scales up, we will certainly look at manufacturing our products here.

Could you elaborate on Kennametal’s sustainability initiatives and the measures you are taking to reduce your environmental footprint?

Sustainability is a very important parameter for us. At Kennametal in Bengaluru, we have an excellent track record in this area. A significant portion of the electricity used at our facility comes from solar power, and we have implemented several initiatives to reduce water consumption. Our CSR efforts also focus on environmental restoration — including lake rejuvenation projects and tree plantation drives. Beyond these initiatives, we also run a global carbide recycling programme. Through this, we buy back used carbide from customers and reclaim it through a specialised process to produce new, high-quality carbide. This not only supports resource conservation but also significantly reduces our environmental footprint.

What digital innovations or smart products is Kennametal currently working on, and how do these advancements contribute to improved safety and performance in mining operations?

We have several initiatives underway to introduce smarter, more digitised products. One such innovation in development is the Smart Drum for mining applications. This product will provide real-time data on drum usage, wear patterns, and failure trends, enabling predictive maintenance and improved operational efficiency. It’s currently in the development stage and will be launched soon. When it comes to safety, Kennametal has always been recognised for its uncompromising focus on quality. Our products are designed and tested to deliver consistent performance throughout their lifecycle, ensuring they do not fail unexpectedly. Quality remains the cornerstone of safety in all our tools and solutions.

How do you view the growth outlook for India’s coal mining sector, and how is Kennametal positioning itself to support this expansion?

India is one of the key regions where coal mining is expected to witness significant growth. From a production level of around 800 million metric tonnes, the country has already crossed the 1,000–1,100 million marks, and projections indicate it could reach nearly 1,500 million tonnes in the coming years. With this surge in mining activity, the focus will increasingly be on enhancing productivity, efficiency, and cost-effectiveness.

At Kennametal, we are preparing for this shift by developing high-performance, durable tools and solutions that help customers achieve greater output with reduced downtime and maintenance. Our focus remains on delivering technologies that improve both productivity and sustainability in mining operations.

Can you explain how Kennametal’s solutions enhance productivity and reduce operational costs, particularly in mining applications?

Value is undoubtedly a key factor in today’s competitive market, and at Kennametal, we have always focused on delivering high-value solutions that enhance productivity and efficiency. Our products are designed and engineered to help customers achieve more output at a lower operational cost. For example, in several mining applications, our tools have demonstrated productivity improvements of up to 20%. To put it simply, if a customer was producing 100 tonnes with a standard set of tools, with Kennametal’s tools, they can achieve around 120 tonnes — without any major additional capital investment. Our focus has always been on providing high-quality, reliable products that deliver measurable value. We also take pride in maintaining a robust and stable supply chain. Despite global challenges in the availability of tungsten carbide, we have managed to ensure consistent supply to our customers, thanks to our integrated sourcing and manufacturing capabilities. Another emerging trend we see is closer collaboration with OEMs to develop customised solutions. At Kennametal, we are actively working with our OEM partners to co-create application-specific tools that deliver superior performance and cost efficiency.

How does Kennametal approach application-specific customisation, and what role do your collaborations with OEMs play in developing tailored mining solutions?

At Kennametal, we offer both standard products and customised solutions. Not every mining application can be addressed with standard tooling, as each site often presents unique conditions and challenges. For instance, even within a single category of tooling, you may find multiple variants designed for different applications — whether for surface or underground mining. Whenever we encounter applications that require a more tailored approach, we work closely with customers or OEMs to design and develop tools that meet their specific operational requirements. We actively customise our products to ensure optimal performance for each unique mining environment. We do have collaborations with OEMs, both in India and globally, for some of the products we manufacture. However, due to the confidential nature of these partnerships, I’m not in a position to disclose specific names. These collaborations enable us to co-develop and customise tooling solutions that meet the unique requirements of our OEM partners and their end customers.

How important are OEM collaborations in developing customised tooling solutions at Kennametal?

We do have collaborations with OEMs, both in India and globally, for some of the products we manufacture. However, due to the confidential nature of these partnerships, I’m not in a position to disclose specific names. These collaborations enable us to co-develop and customise tooling solutions that meet the unique requirements of our OEM partners and their end customers.

What role do you see AI playing in the mining sector, and how is Kennametal leveraging it within your operations?

I think it’s still early days for the application of AI in the mining sector. At this stage, its direct impact on mining operations may be limited, but we are beginning to see meaningful use cases in areas like design and product development. For instance, within Kennametal, there was a particular design activity that earlier took about eight weeks to complete. After integrating AI into the process, we were able to reduce that timeline to just eight days. This clearly shows the potential of AI in enhancing design efficiency and accelerating product development cycles. So, while AI’s broader role in mining is still evolving, its contribution to improving our internal design, engineering, and manufacturing processes is already becoming evident.

Tags