Material Handling Equipment: Manoeuvring with AI

With the integration of artificial intelligence (AI), warehouse material handling equipment are becoming smarter, faster, and more efficient. AI-driven solutions, such as autonomous robots, smart inventory systems, and predictive analytics, are revolutionising warehouse operations. These innovations not only optimise space utilisation and reduce errors but also enable warehouses to operate with greater flexibility and speed, ensuring that businesses can keep up with the growing expectations of the modern consumer

Over the past few years – especially in the aftermath of the COVID-19 pandemic – India’s warehousing sector has emerged as one of the fastest-growing segments of the economy. Accelerated by a surge in e-commerce, shifting consumer expectations around delivery timelines, and a renewed focus on supply chain resilience, the sector has seen record investments and rapid infrastructure expansion.

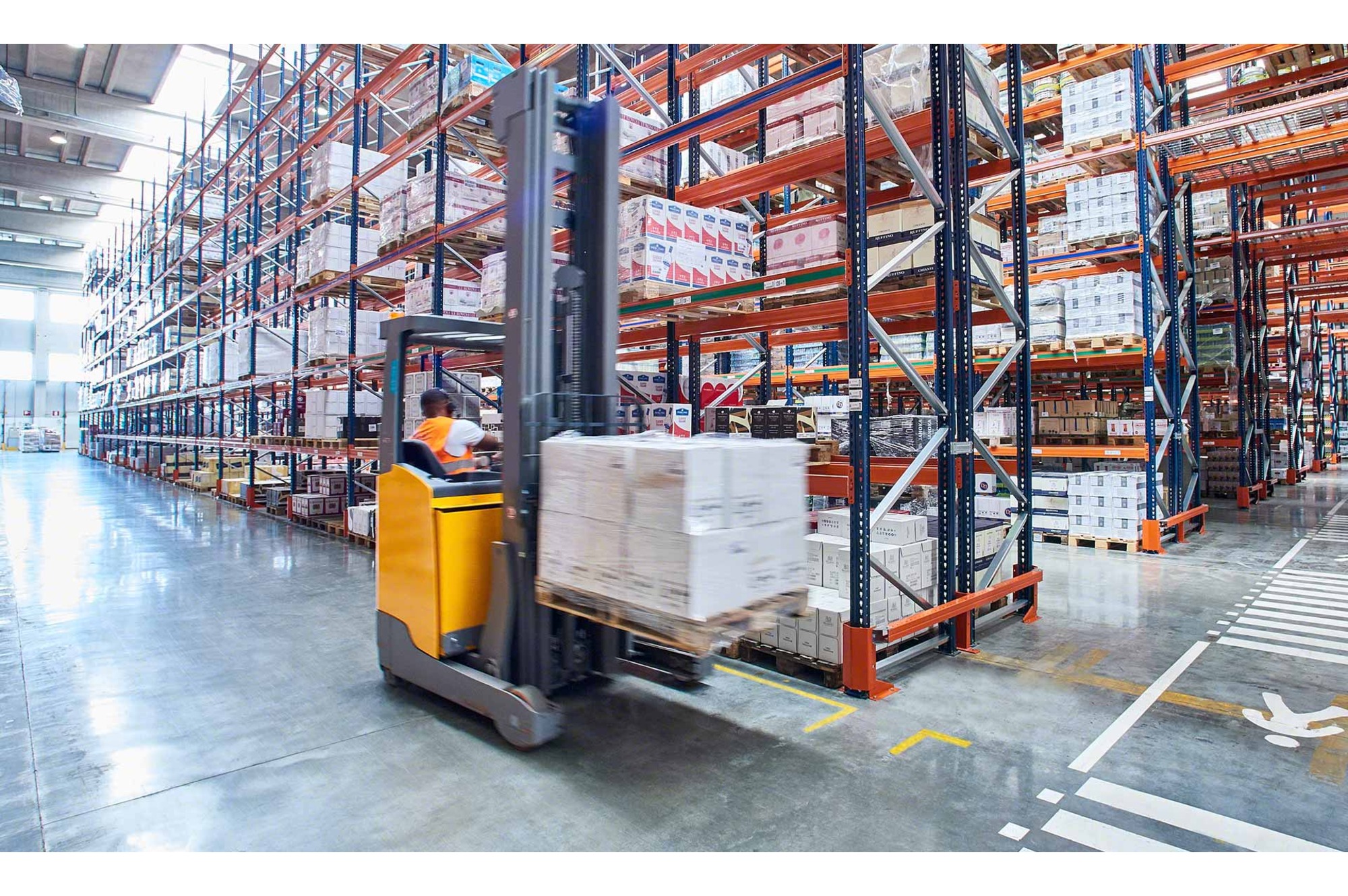

Warehouses today are not just storage spaces; they are high-efficiency hubs designed for swift, accurate, and seamless movement of goods. At the core of this transformation lies Material Handling Equipment (MHE)—a critical enabler without which modern warehousing operations cannot function. From transporting and stacking to sorting and retrieving, MHE ensures that daily warehouse tasks are executed with speed and precision. As warehouse layouts become more compact and vertical to optimize space, equipment must be designed to maneuver through narrow aisles and tight corners, handling increasingly complex operations with agility.

It’s no surprise, then, that the market for warehouse-focused MHE is experiencing substantial growth. According to industry data, India’s MHE market in warehouses was valued at USD 10.57 billion in 2024, and it is projected to reach USD 22.48 billion by 2033, registering a CAGR of 8.08% from 2025 to 2033. This explosive growth reflects not only the rising number of warehouses but also the growing preference for automation and efficiency in material movement.

Integrating advance technology

As warehouses scale up to meet the demands of a hyper-connected and on-demand economy, technological innovation in material handling equipment (MHE) has become indispensable. Traditional, manually operated equipment is being rapidly replaced or augmented by intelligent, sensor-driven, and automated systems that promise greater efficiency, safety, and real-time control. At the forefront of this innovation are automation, electrification, connectivity, and AI-powered systems that are transforming how goods are moved, stored, and tracked inside warehouses. “Among our latest innovations, the electric forklift stands out as a cutting-edge addition to the portfolio of Good & Green products, providing customers with a superior technological experience. The electric driven forklifts introduced in last 2 years are 10 percent more energy efficient than their predecessors. Electric forklifts boast several advantages over their diesel counterparts, including up to an 80 percent reduction in operating expenses, enhanced manoeuvrability, and adaptability. Within our electric forklift range, we offer three distinct models: UNO, NEO and BRAVO,” Neville Mevawala, Head of Sales & Marketing, Godrej Material Handling.

One of the most notable advancements is the rise of Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). These self-navigating machines are equipped with LiDAR, cameras, and onboard sensors to detect obstacles, follow predefined routes, and dynamically adjust paths—enabling them to operate independently in busy warehouse environments without human intervention. They are increasingly used for tasks such as transporting pallets, restocking shelves, and feeding goods into packing stations. Bengaluru-based startup ANSCER Robotics has secured $2 million in a seed funding round led by Info Edge Ventures, aiming to scale up its range of Autonomous Mobile Robots (AMRs) for warehouses and manufacturing facilities. The company develops a suite of robotic solutions including pallet movers, tuggers, and conveyor systems, and has already marked its presence in key international markets such as India, the United States, Singapore, and Japan. Among its key offerings is the Pallet Lifting Robot (PLR) Series, which includes the PLR1000 and PLR2000, capable of handling payloads of 1,000 kg and 2,000 kg respectively. These robots are engineered to autonomously transport heavy pallets across warehouse floors, reducing manual labor and increasing operational throughput. ANSCER’s portfolio also includes the PSR2000 (Pallet Stacking Robot), which automates the stacking of goods, optimizing space utilization within warehouse storage zones. Powered by artificial intelligence and real-time navigation systems, these robots are designed for seamless integration with existing warehouse infrastructure. Their ability to adapt dynamically to changing environments minimizes downtime and enhances overall warehouse efficiency—making them a valuable tool in the growing trend of smart, automated logistics operations.

In parallel, IoT-enabled forklifts and stackers are now being deployed to offer real-time monitoring of equipment health, battery status, and usage patterns. This integration of sensors allows for predictive maintenance, minimizing downtime and extending equipment life. Electric and lithium-ion-powered MHE is also gaining ground as businesses look to cut emissions, reduce operating costs, and align with sustainability goals. Godrej Consumer Products’ recently launched warehouse integrates advanced material handling capabilities such as angular docks, dock levellers and automation designed to manage over 60,000 cases daily. GCPL has also embedded cutting-edge safety and monitoring technologies including AI-ML powered warehouse monitoring, IR-based fire alarm systems, temperature and gas sensors, and a centralized warehouse control centre.

Moreover, Warehouse Management Systems (WMS) and Digital Twin technologies are being integrated with MHE to enable synchronized and optimized workflows. By using AI and machine learning algorithms, WMS can now dynamically assign tasks to robots, optimize picking paths, forecast demand surges, and simulate various layout scenarios to improve efficiency. Addverb Technologies, a leading robotics and automation firm, has unveiled a new suite of intelligent systems aimed at enhancing warehouse efficiency, safety, and adaptability across industries. The latest innovations include Trakr 2.0, a quadruped robotic assistant; HOCA, a high-speed carousel-based order consolidation system; and Brisk, an intuitive user interface designed for streamlined picking operations. Trakr 2.0 is a four-legged assistive robot engineered to support warehouse personnel in material handling tasks. With a payload capacity of up to 20 kg, 90-minute battery life, stereo vision cameras, and gesture-based command functionality, it offers a unique combination of agility and utility for navigating dynamic warehouse environments. The HOCA system (High-Speed Order Consolidation and Automation) is built for efficient batch picking and order fulfillment. It features a modular carousel that comes in sizes ranging from 5,900 mm to 46,700 mm, supports multiple carrier configurations, and can handle payloads up to 900 kg. Designed for flexibility and maximum space utilization, HOCA is ideal for high-throughput, multi-SKU operations. Complementing these systems is Brisk, an advanced user interface that elevates warehouse picking processes. It incorporates gesture-based interaction and glove-based EAN scanning, with adaptive lighting features that ensure consistent performance across varying warehouse conditions. Brisk improves operator comfort and speed, reducing the cognitive load during complex picking tasks. Bosch has launched its Supply Chain Studio, a cloud-based suite of tools aimed at enhancing supply chain efficiency and visibility. The Studio aims to address key gaps in transport and warehouse management, last-mile operations and more.

Voice-picking systems, wearable tech, and augmented reality (AR) headsets are further streamlining order picking and inventory tracking, especially when used in conjunction with robotic MHE. For example, a warehouse operator wearing AR glasses can receive real-time instructions, while a robotic picker handles the actual retrieval—cutting down on errors and speeding up order fulfillment. Nestle India has launched its state-of-the-art Distribution Center (DC) in Bhiwandi, Maharashtra. This is the first DC in Nestlé India to have a Digital Twin, a planning tool for the warehouse operations which helps in simulating different scenarios in a virtual environment and take actions accordingly, thus helping with better planning and preparedness. The distribution center is also equipped with AI-enabled CCTV, Operations Command hub, digital rack inspection system, and sensor-fitted material handling equipment, thus strengthening the security system. Global warehouse robotics provider has launched Next Generation of Skypo®︎ system with higher performance, improved storage density, and advanced software features The Next Generation of Skypod comes with a number of design improvements including a new and more compact Skypod robot, a workstation for robot-to-robot picking, high-throughput Exchanger, and denser storage. These redesigns combined with new software features improve the throughput at a single workstation by 50% while also enhancing storage density up to 30% compared to the previous generation.

In short, the next-generation MHE is not just about moving goods—it’s about intelligent, connected, and automated systems that drive operational excellence. As India’s warehousing industry embraces Industry 4.0, technology-driven MHE is becoming the key enabler of scalable, responsive, and future-ready logistics operations.

Green MHE

As the warehousing and logistics industry expands rapidly, sustainability has emerged as a key priority, influencing equipment choices, energy consumption, and overall operational strategies. Modern warehouses are increasingly shifting away from diesel-powered and fossil fuel-based material handling equipment toward electric, battery-operated, and energy-efficient alternatives. Lithium-ion batteries, in particular, are gaining traction due to their longer life cycles, faster charging capabilities, and minimal maintenance needs compared to traditional lead-acid batteries. This shift not only reduces the carbon footprint of warehouse operations but also lowers long-term operating costs. “Due to the government’s proactive push for Indian manufacturers to embrace sustainable manufacturing practices, there has been a notable transition from diesel-powered forklift trucks to electric alternatives within shop floors and warehouses. Over the past few years, our relentless dedication has been focused on the substantial reduction of carbon emissions. With our electric forklift trucks, we save 58K tonnes of carbons per year and aim to save 100K tonnes per year by 2025,” says Neville Mevawala.

Many warehouses are now incorporating solar power solutions, energy-efficient lighting, and smart climate control systems to further reduce energy use. When paired with eco-friendly MHE – such as electric forklifts, hybrid automated guided vehicles (AGVs), and regenerative braking technologies – warehouses can significantly cut greenhouse gas emissions and meet global sustainability targets. In addition, manufacturers of MHE are adopting circular economy principles by designing equipment with recyclable components and promoting refurbishment and reusability. Green certifications and environmental compliance standards like LEED (Leadership in Energy and Environmental Design) are also becoming benchmarks for modern warehouse design and operation. By investing in sustainable MHE, companies not only contribute to environmental protection but also gain competitive advantages through regulatory compliance, improved brand image, and greater appeal to ESG-conscious investors and clients.

Manoeuvring challenges

While warehousing material handling equipment (MHE) has made significant strides in innovation and technology, its adoption and integration continue to face notable challenges. A major barrier is the high initial investment required for advanced automated systems such as Autonomous Mobile Robots (AMRs), Automated Storage and Retrieval Systems (ASRS), and lithium-ion-powered forklifts. For many small and mid-sized warehouse operators, these costs are prohibitive without access to financial assistance or a clearly defined return on investment. To address this issue, several MHE manufacturers have partnered with leading banks and non-banking financial companies (NBFCs) to offer tailored financing solutions, making advanced equipment more accessible to a broader segment of the industry. Like many other industries, the material handling equipment (MHE) sector also faces a shortage of skilled manpower, especially in Tier-II and Tier-III cities where industrial activity is growing rapidly. This skills gap poses a challenge to the effective operation and maintenance of modern MHE systems. In response, several equipment manufacturers have initiated skill development and training programmes aimed at equipping operators with the technical knowledge and practical expertise required to safely and efficiently manoeuvre MHE machines in increasingly complex warehouse environments. Compatibility issues between legacy systems and new automation technologies also pose integration challenges. Moreover, frequent power disruptions, lack of standardization in warehouse design, and limited awareness about the long-term benefits of automation further impede widespread adoption. Addressing these barriers will be crucial to realizing the full potential of smart and efficient warehouse operations in India.

While challenges exist, the warehouse MHE sector in India is ripe with transformational opportunities driven by the ongoing boom in e-commerce, third-party logistics (3PL), manufacturing, and the government’s focus on infrastructure development. The rollout of policies like the PM Gati Shakti Master Plan and National Logistics Policy is creating a favorable environment for large-scale warehouse expansion, especially along industrial corridors and near consumption hubs. This growth is fueling demand for efficient, scalable, and tech-enabled material handling solutions. The increasing trend toward multi-level and automated warehouses in urban centers has opened up new avenues for vertical MHE such as reach trucks, stackers, and robotic pickers. Additionally, India’s emerging status as a global manufacturing and export hub under initiatives like ‘Make in India’ is encouraging global MHE players to localize production and form strategic partnerships. There is also a rising interest in MHE-as-a-Service (MHEaaS) models and rental-based deployments, allowing smaller businesses to adopt high-end equipment without large capital outlays. With digitization, sustainability, and automation becoming key priorities, the future holds immense potential for companies that can offer customized, intelligent, and eco-friendly MHE solutions to India’s rapidly modernizing warehouse ecosystem.

Growth trajectory ahead

India’s warehousing sector is undergoing a transformative shift, driven by rapid digitalisation, rising consumer expectations, and government-backed infrastructure initiatives. At the heart of this evolution lies the growing importance of Material Handling Equipment (MHE), which not only enhances operational efficiency but also enables scalability, safety, and sustainability. While challenges such as high capital costs, skill shortages, and integration barriers persist, they are gradually being addressed through innovative financing models, focused skilling efforts, and technological advancements. As automation, AI, and sustainability continue to reshape the logistics landscape, the MHE industry is poised to play a pivotal role in powering India’s future-ready, smart warehouses.

Tags