- by Jogesh Sharma, Head – Industrial Lubricants, GP Petroleums

After two months in a lockdown imposed due to the COVID-19 pandemic, the focus has now begun to shift to opening up the economy. As factories begin operating again as part of the gradual easing of the lockdown rules, it is important that certain precautions are taken before powering up all of the equipment and machines.

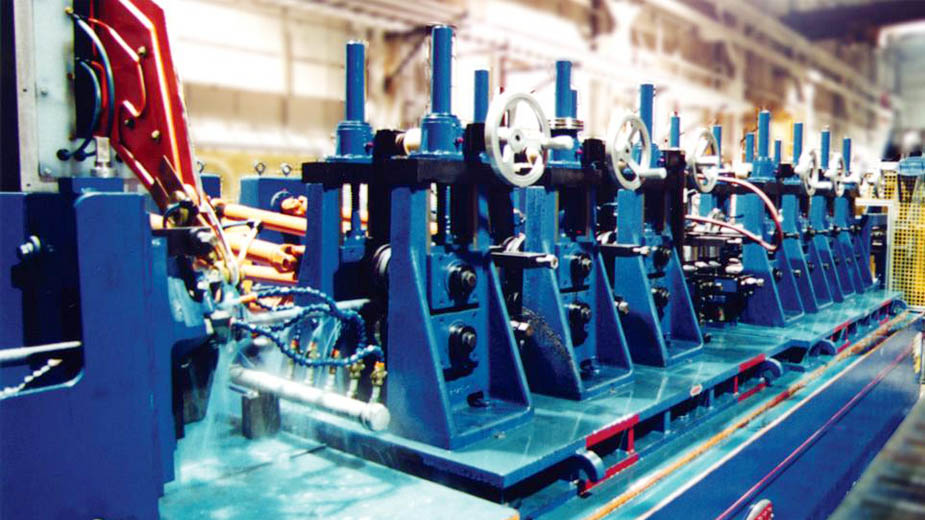

Factories have lain dormant for nearly eight weeks now. The machinery, which practically ran non-stop, has now remained unused for an extended period of time. As a result, thorough maintenance must be carried out before restarting operations. This includes not just the machinery itself but also coolants.

Water soluble Coolants are universally used in any factory running any machine. But often when it comes to maintenance, coolants are generally at the bottom of the to-do list. That can be a mistake that can cause catastrophic and expensive damage to your factory equipment.

Coolants counteract the friction generated by the moving parts in factory machinery so that they don’t overheat and break down.

So they are critical to the smooth operation of any factory. Yet, just like machines, coolants can degrade after long periods of disuse. For one thing, coolants are susceptible to bacterial infection in the absence of regular use. The bacteria can lower the pH level of the coolant, reduce its life, degrade its stability, and lead to health risks for factory workers and in the worst case scenario even strip it of all its properties.

The longer the coolant stays static and stagnant the higher the chance of bacterial infection. Running this contaminated coolant through your equipment can lead to damage like rust and corrosion that can prove expensive and lead to long downtimes, not what you want when your factory has already been idle for nearly two months.

The contaminant may not always necessarily be bacteria either. Dirt and oils can also accumulate on the surface of the coolant when it sits stagnant for long. These destabilize the emulsion, degrade the coolant’s properties and lower its life.

Thus great care must be taken, specifically with respect to coolant quality, when restarting factories and there are some precautions that can be followed which factory operators can use their stores of coolant even though it has been sitting stagnant.

To begin with the coolant needs to be recirculated for at least 10 to 15 minutes. Pumping air into it will also help as it will aerate the coolant and restrict the growth of anaerobic bacteria.

The coolant also needs to be thoroughly checked - its concentration, its pH levels, hardness, chloride and bacterial count all need to be within normal parameters before use.

Whatever you do, do not turn on the coolant systems until this is done. Otherwise there is a risk that degraded coolant could be introduced into the internal cooling systems which would in turn contaminate any fresh coolant that may be pumping through the cooling lines. If after your checks, the coolant is still found to be not satisfactory, then the safest option is to dispose it off & replace it with new fresh coolant.

Ultimately, think of a factory as a living thing. It needs maintenance after idling for so long. It can’t just go from idle to operating at peak efficiency. And checking the condition of the coolant is a key part of that maintenance. Because the last thing you need after a two month shutdown is even more downtime.