PESTECH’s Cambodia substation and transmission system project bolsters region’s electricity

Substations and transmission line to bring the power

A new network in Cambodia was designed to meet the power needs of an area that is experiencing development and urbanization. Diamond Power awarded a contract to PESTECH International Berhad to design, supply, deliver, erect, and commission the 230-kilovolt Kratie and Kampong Cham Substation and Transmission System in Cambodia. An objective of the custom-designed high voltage (HV) and extra high voltage (EHV) system is to prolong the life and reliability of the transmission and distribution assets.

Kratie is a province located in northeastern Cambodia and Kampong Cham is the third-largest city in the country, situated about 57 miles away from Kratie. Both areas are not tourist destinations, but backpackers pass through Kampong Cham during the high season seeking accommodations as it is a transit point between Siem Reap and Phnom Penh, both of which are popular tourist spots.

The new Kratie 230/22-kilovolt substation will serve as a major collection center of electricity power from additional mini-hydropower plants and will be connected to the national power grid of Cambodia.The 125-kilometer 230-kilovolt duplex ACSR bittern transmission line will connect the new Kratie Substation to an updated Kampong Cham Substation. This line will transfer 700 megawatts of electrical power from Sesan Hydropower Plant, which is nearing completion in the upper Mekong area, to the Kratie and Kampong Cham regions. Power from the plant will also be transmitted through the Kampong Cham-Kratie transmission line to Cambodia’s capital, Phnom Penh.

Comprehensive engineering design by PESTECH

Established in 1991, PESTECH International Berhad is an electrical trading company in Malaysia that specializes in creating electrical power facilities in developing countries and has a market capitalization of over MYR 1 billion.The company has evolved from delivering power transmission infrastructure to building and operating transmission assets, embedding system software and product development, and most recently power generation and rail electrification.

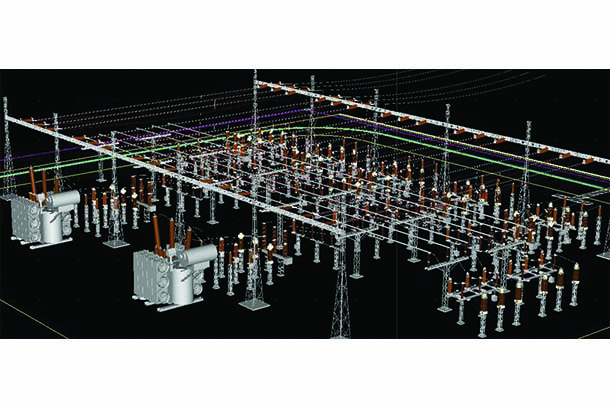

PESTECH was contracted to do the transmission portion of the project and the primary and secondary design of the substation system for the USD 92.2 million project. PESTECH created a conceptual design of the substation systems and assembled, installed, tested, and commissioned the 230-kilovolt switchyard within the existing Kampong Cham Substation, a new Kratie 230/22-kilovolt substation, and the interconnecting 230-kilovolt duplex ACSR bittern transmission line that connects the Kampong Cham Substation to the Kratie Substation. The primary design included designing the substation layout and the secondary design included the control and relay panel protection panels.

Advancing past manual methods

Previously, the engineering team designed and manually updated 2D hand-made drawings, conducted manual component calculation, and used AutoCAD. This methodology was inconsistent, time consuming, labor intensive, and prone to human error. Additionally, the manual method created a divide between the electrical and physical design. Drawings and design deliverables were dispersed among all stakeholders, so information sharing was disorganized and inefficient, often impacting construction when outdated files were referenced, necessitating expensive and time-consuming rework. PESTECH’s previous schematic diagram also did not incorporate intelligent functions, such as clash detections, lightning protection design simulation, and automated functions for drawings and report generation.

Visualization of the 3D substation design was essential for preparing work before and during construction, and the use of ProjectWise was integral for collaboration across departments, both on and offsite. Bentley Substation and Navigator were vital in ensuring project success in spite of the many situational challenges imposed on the project because of the isolated location.

Integrating the 2D electrical and 3D physical designs

PESTECH engineers used Bentley Substation for the 3D physical design and 2D electrical design. PESTECH’s engineering team created a systematic database and catalog. It took the team about one month to put together a full set of libraries that consisted of hundreds of parts. After the database was fully comprehensive, the design drawings used a pick and drop method for the electrical design of the 3D substation layout and the 2D electrical schematics of the control relay and protection panels. This saved the team time on submissions and revisions.

Bentley Substation integrates both 3D substation design with 2D electrical protection and control schematics and panel design into one application. This combined platform provided the engineering team with a seamless review of the project, eliminating the need for multiple applications. The unified environment also limited manual coordination needed to keep the electrical and physical designs constant and it promoted greater collaboration across the multi-discipline team. The unified design environment eliminated data re-entry, reduced manual coordination, enabled cross-discipline collaboration, curtailed drawing errors, avoided rework, enhanced efficiencies in design work, and created an interconnected design.

Utilizing the Bentley solution for the primary and secondary design phases of the project optimized workflows and the team of electrical and civil engineers designed and constructed the project to meet all standards, electrical parameters, and safety requirements. The engineering team developed libraries, databases, and templates compliant with Cambodian standards.

Intelligent database software

During the primary design, the substation system needed to be laid out, including transformers, gantry towers, large cables, and circuit breakers. It was essential that these designs adhere to regulatory standards and be created via accurate engineering calculations. Bentley Substation capabilities helped construct the layout in a matter of seconds, whereas manual methods would have taken weeks. The team produced visual simulations of lightning protection of the area, grounding grid design functions, and took advantage of navigational functionalities with components interlinked in the parts database through Bentley Substation. Also, hook point technology in Bentley Substation enabled 3D components to snap automatically,saving significant time.

Additionally, Bentley Substation created an intelligent substation digital engineering model that helped the team automate their design drawings and reports. Bentley Substation significantly reduced time for the project team through automatic diagram and report generation, real-time post-process error checking, smart PDF generation, and simple navigation of the intelligent 2D and 3D models.

Plug-ins were developed with the API generated information automatically, saving time. The Automatic Wire Numbering plug-in automatically named thousands of wires within a minute and panel wiring numbers were generated instantly. Over 100 kinds of panels were used in the substation that required thousands of schematics pages, because each panel has over 50 components. With the Graphical Report Plug-in, all the schematics pages were generated automatically within a few seconds after the schematic design was complete. Other reports, such as bills of materials, cable schedules, tables of contents, and terminal connection diagrams were all automatically produced with the report templates prepared.

Accurate results, real-time sharing

Bentley Substation and Navigator helped visualize the site with accurate dimensions of the site even though it was in a secluded, hilly, and forested area. Bentley Navigator Mobile was essential for the management, consultants, contractors, and engineering team. All stakeholders could have a 3D digital model on-site and all required changes could be communicated to other team members in real-time. ProjectWise was used to easily share documents across multiple departments for seamless collaboration among all teams.

Bentley solution saves time and money

PESTECH has estimated that they saved nearly 70 percent in time and a total of RM 50,000 on the project. Schematic drawings were completed in under seven days, when they would normally take between two to three weeks with prior methods. 3D design in Bentley Substation took three days, whereas similar 3D design in CAD took two weeks and required each design to be drawn and viewed separately. Additionally, the application automatically generated cable schedules within one hour for the entire project when it would typically take three days to check and document each cable. A further example of the time savings with Bentley software is evident in how a plug-in allowed terminal function diagrams to be generated in just seconds rather than the three days it would have taken to manually document and check the report.

Through Bentley software, the PESTECH engineering team achieved accurate generated drawings and documentation, saved time on drawing production, saved money in procurement, and delivered better visualized substation presentations with3D primary and 2D secondary engineering designs unified in a single application.

With more power comes a greater impact

With Cambodia growing as a tourist destination and Kampong Cham having roads that connect to major Cambodian cities, added electricity to this region of the country through the substation is vital for future development. Concurrent with the construction of the substation is the construction of additional highways between Kampong Cham and the capital city of Phnom Penh. These routes will benefit the tourism industry as well as the surrounding community as it allows for better transit access for cars and buses. Further electricity in the area is also set to spur construction of hotels and resorts.

Bentley Substation’s unique ability to integrate primary and secondary designs, the flexibility of Bentley’s software, its expansive capabilities, and its customizable environment with a variety of software components that can be integrated into a single platform were the greatest assets of the technology. After the project is completed, the Kratie and Kampong Cham area will have enhanced electricity usage that supports the quick development of the region and PESTECH will operate and maintain the power transmission system for a 25-year period.

Cyndi Smith, Senior Industry Marketing Director, Bentley Systems’ Utilities, Water, and Communications Industries

@EPC World Media